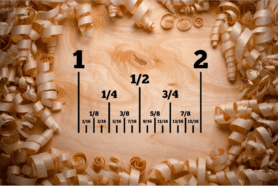

Data is a new oil and businesses understand the tremendous importance of data in a new business world. For a very long time, PLM businesses were relying on the “data locking” paradigm. Although no company specifically declared data locking as a strategy, in reality, once you’ve been getting into a software universe of a single vendor, it would be very hard to get out.

Data vs Application – what is more important and why?

Data is more important than applications. This is the reality of the manufacturing industry. The lifecycle of companies and products they are developing is much longer than applications and software. What was true only for large aerospace and defense customers with a long lifecycle, today is the reality for many smaller companies. Companies are looking for PDM/PLM software that can speed up the product development process, but the fast company and product development accelerates company transformations and brings a question of moving between PLM platforms more often than it happened in the past. Mergers and acquisitions are other factors that contribute to the problem of data migrations. Legacy PLM software, which is going out of support, and some other PLM companies that are going out of business are completing the picture. As a result, companies are more than ever sensitive today about data management, data ownership, and data migrations.

Declaration of Data Independence

Companies are looking at how to separate data and applications. Such data mobility can be a good solution, but the reality is much more complex. Each company creates its own data abstraction level and if it is poorly done, you might be stuck forever with the data stored in some legacy database and, as a result, develop a data survival plan.

When you’re selecting a PLM system, you need to check that a vendor doesn’t do any data obfuscation and that the data model is transparent and allows you to get it out of the system and import it to the stake in a very easy and simple way.

SaaS PLM and Web Services

From a very early beginning, manufacturing companies were suspicious of SaaS businesses, which were criticized for the creation of closed systems that will hold customers as a prisoner and will create problems to get this data out when needed. Well, it was true for old hosted PLM systems that were the same legacy PLM platforms hosted in the cloud services like AWS. The absence of Web API was a bad thing for these systems and therefore accessing the information was extremely complex or even impossible.

The change was coming with the introduction of modern SaaS PLM systems developed as web services and providing REST API as a normal way to communicate (similar to all other web platforms). Such an API gives a new and simple way to get data out of the system and import it to the system when needed.

At OpenBOM, our strategy was to lead the way for the industry to provide a simple and flexible service that can help to manage engineering and manufacturing data while keeping data APIs open and available to everyone. This is part of the OpenBOM strategy.

Customer Migration Story

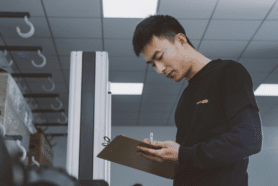

As an example of how the OpenBOM API strategy and flexible data model can work in a real life, I want to bring the story of Barron Weather company that came to OpenBOM to help to migrate from the old PLM system to OpenBOM. Read the story Huntsville, Alabama-based Baron is replacing the end-of-life PLM system with modern OpenBOM Web Services and uses REST API to migrate and consolidate product data. Here is my favorite passage.

OpenBOMs modern REST API was just what Baron was looking for. We hired an intern to manage the migration of all our component information from FusePLM. We conditioned the FusePLM full data export using Python to add important features like data references to our Zoho repository and then loaded it into OpenBOM using the OpenBOM public API’s. The documentation is online and we found the process met our needs. We bought OpenBOM because we needed to bring all our FusePLM data forward to a modern system. As of now, we have completely migrated from FusePLM to OpenBOM.”

Simply put, OpenBOM provided a robust mechanism to bring the data in and to ensure data transformation is seamless with no data loss.

Conclusion

OpenBOM’s strategy is to provide an open and transparent mechanism to bring data in and export data out to ensure, that the data is the main asset that can travel between PLM systems. REST API is the way to communicate and use multiple stakes. Combined with out-of-the-box import, OpenBOM’s capabilities to migrate customer data are robust and powerful.

REGISTER FOR FREE to check how OpenBOM can help you today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.