There are many choices for PLM systems on the market, but not all of them are created equal. In my article, I presented multiple options on how cloud technologies can be used to empower PLM infrastructure and applications. Between hosting, enterprise SaaS and cloud-native SaaS platforms, I want to stop and talk about what makes OpenBOM cloud-native SaaS and what are the differences that allow OpenBOM to bring a unique value and scale from individual engineering contractors, to SME industrial companies, and Fortune 500 enterprises.

When it comes to cloud-native PLM systems, there are a few key differentiators that you should keep in mind. In this blog post, we’ll explore three differentiators of cloud-native PLM systems: scalability, flexibility, and collaboration. By understanding these three core concepts, you’ll be able to make a more informed decision when selecting a PLM system for your business.

Gartner’s Hype Cycle Perspective

One of the top analytical and research companies, Gartner, published their Hype Cycle for Manufacturing Digital Optimization and Modernization 2021. According to Gartner, cloud-native PLM applications are designed specially to take advantage of cloud infrastructure and they are sold via SaaS (Software as a Service) subscription model.

Moreover, cloud-native SaaS PLM is architectured to take full advantage of cloud computing power and model. Legacy (mainstream) PLM applications are required VPN or hosted in the cloud and therefore provide limited scale, but most importantly, cloud-native PLM systems provide an unprecedented level of collaboration that cannot be achieved in hosted cloud applications because of their single-tenant data management architecture.

Two of the most important business impacts of cloud-native multi-tenant platforms is that it improves the ability to use applications and collaborate for everyone in the company, but also across multiple companies. In a modern manufacturing world, multiple companies’ use case goes much beyond a traditional OEM-Tier1-n scenario, but are also critical for multiple business transformations such as joint ventures, M&A activities, and other use-cases.

According to Gartner, cloud-native PLM platforms are leaving the period of “Trough of disillusionment” and entering the period of “Slope of Enlightenment” according to Gartner’s Hype Cycle terminology.

How Different Is OpenBOM SaaS PLM?

In today’s blog, I would like to share with you 3 fundamental differentiation elements of OpenBOM that position it aside from mainstream PLM systems.

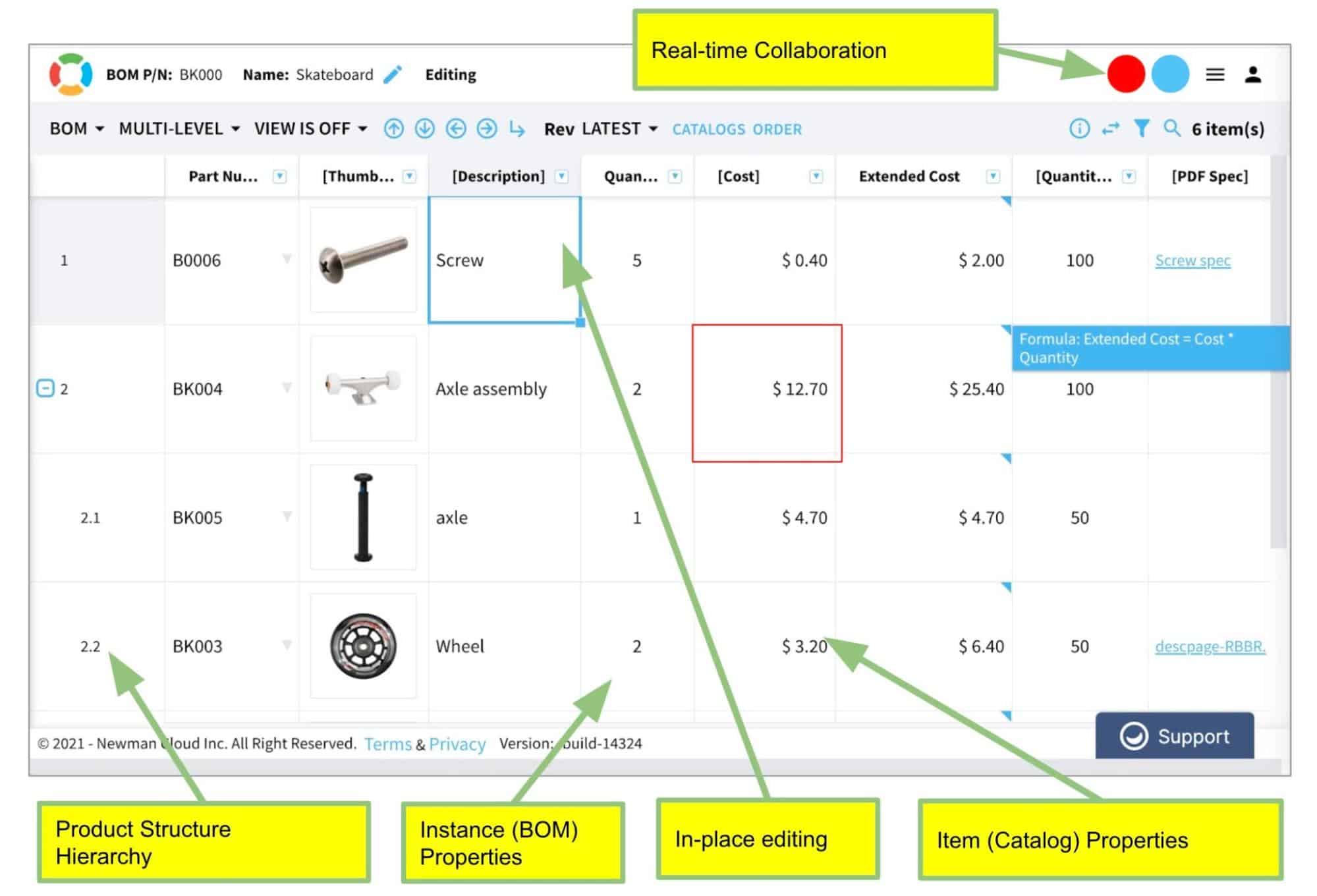

- Multi-tenant flexible data management platform

- Real-time collaboration & simultaneous data editing and collaborative workflow processes

- Instant data sharing across multiple teams and companies

The data management foundation of OpenBOM is where the differences start to show up. A distributed catalog system allows users to define item types and customize the data model for each type. They are flexible and, most importantly, can be provided by multiple users and even companies. You can think of the distributed item data set of a representation of all items used in the company both developed by the R&D department as well as provided by contractors, suppliers, and other players (eg. equipment distributors). Special data management mechanisms ensure data integrity, Part Numbers control, and the ability to extend data models dynamically in real-time.

Combined with a unique user experience, the OpenBOM data management platform provides an instant data save without the need to perform special operations to save data. Even more, two or more people can perform editing and viewing of the data at the same time, capturing history, managing revisions, and changes.

Change management capabilities provide a seamless way to present a change process and real-time visibility on the approval workflow. These workflows use the same collaborative technology with instant data sharing. Multi-tenant data management capabilities allow you to bring users from multiple teams and companies to participate in the process, which is impossible in any mainstream PLM software (even hosted in the cloud).

Why pay attention?

According to CIMdata cloud PLM research, about 70% of industrial companies are looking at how to optimize and modernize their PLM stack and considering cloud PLM software as an option for their next platform. This is an incredibly large number, which means that manufacturing companies are on the move and looking at how to adopt modern PLM systems and shift towards a better way to manage product data and business processes. A typical large manufacturing company is using a PLM tech stack developed 25 years ago, which cannot be easily upgraded and modified. A typical SME company is using a bunch of Excel files (or Google sheets) to do the same. This is not the right way to do business in the 21st century.

Conclusion

You can host mainstream PLM software in the cloud, but you cannot turn it from a single-tenant SQL-based architecture to a cloud-native multi-tenant platform. This is a generational shift, which provides unique capabilities that will never be possible to develop in 20-25 year old PLM data stacks. Cloud-native PLM software might not be that feature-rich, but the gap is shrinking much faster.

Product lifecycle management systems are turning to the cloud-native platform because their much more familiar to modern users, provide clear business values, and can support a wide range of customers from large companies to SMEs and supply chains.

REGISTER FOR FREE to check out how OpenBOM can help revolutionize the way you manage data and coordinate business processes.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.