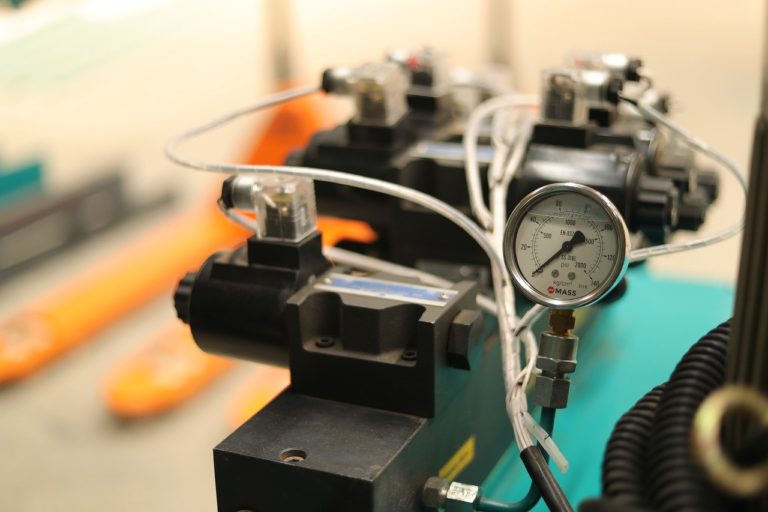

OpenBOM helps to build complex industrial products by managing parts, complex multi-level Bill of Materials, estimates cost and manage vendors and purchasing

The complexity of mechanical and industrial products is increasing as well as the need to have robust tools to design, manufacture, and maintain them. Manufacturing companies are looking for technology to help to improve efficiency and productivity and at the same time, to decrease the cost, improve collaboration. OpenBOM helps to build a comprehensive product information model, multi-level BOMs, perform cost calculation and analysis and to enable real-time collaboration between teams, contractors, and suppliers.

Check What Customers Are Saying?

Pierson designs and manufactures a wide variety of innovative work-holding solutions for rotary, pallet, vacuum, and other applications. Pierson Workholding customers demand quality and reliability. Carlos Acosta, a chief problem solver at Pierson has the same demands when choosing a Bill of Materials management solution – which is why he chose OpenBOM

“We looked at a lot of options for creating and managing Bill of Materials, the CAD-based product didn’t have the ability to create Planning BOMs and Purchase Orders (which we need) and Excel didn’t have any connection to our design process (CAD), which we also required,” says Carlos. “OpenBOM offers a complete Design to Purchase process which includes BOM, Order (planning) Planning BOMs, Vendor Lists and Purchase Orders. As well as inventory control of Quantity on Hand”

FF Robotics Saves Times And Money by Standardizing 16K Individual Components and Optimizing BOMs.

FF Robotics has developed an innovative gripper technology, coupled with a twelve-arm multi-axis robot, to delicately harvest ripe fruits from trees. The harvested fruits are then meticulously placed onto an automated conveyor, which transports them to an 800lb harvest bin for packaging. This entire process mirrors the care and precision of human handling. Given the intricate nature of replicating human gentleness, FF Robotics relies on sophisticated and precise solutions. That’s why they’ve chosen OpenBOM to accelerate the journey of their innovation to market.

“We needed to reduce the number of specific part numbers and OpenBOM makes it easy to understand where each and every one of the components is being used. Something which was not the case when he was using Excel. Getting our BOMs out of Solidworks in Excel was hard. We would add some non-modeled items like hardware then have to manage all those additions individually each time we updated the Excel from Solidworks. Using OpenBOM with SolidWorks and PDMWorks is much much easier, he says. OpenBOM easily manages and tracks our part numbers, something as simple as finding where a part is used is easy with OpenBOM’s where-used command; not having to open our CAD and look for a part is a huge time-saving.”

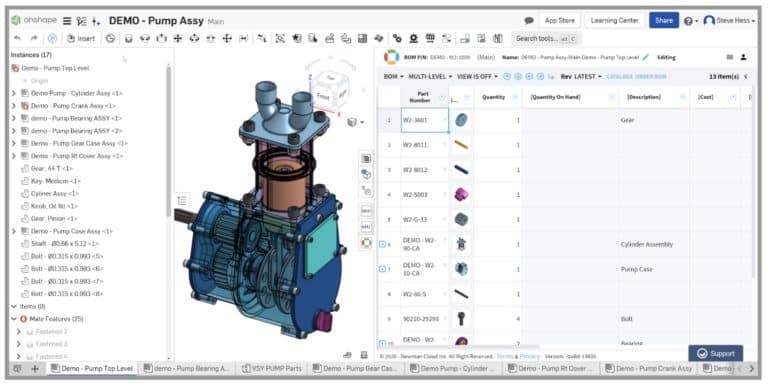

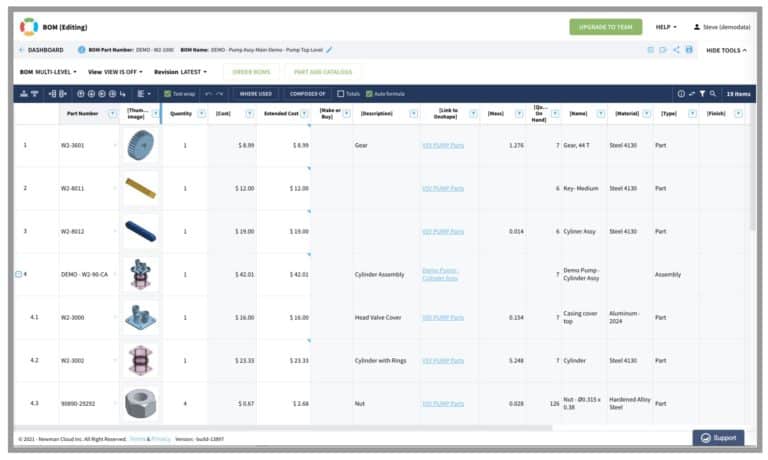

Full Multi-Level Bill of Materials for Complex Assemblies

OpenBOM allows creating a database of items and Bill of Materials using one-click CAD Integrations from 3D design.

Parts, Vendors, and Multi-level Bill of Materials

OpenBOM provides a highly intuitive user interface to navigate and manage Bill of Materials and all related product information.

Read more OpenBOM User Stories Online.

Read more OpenBOM stories on G2.