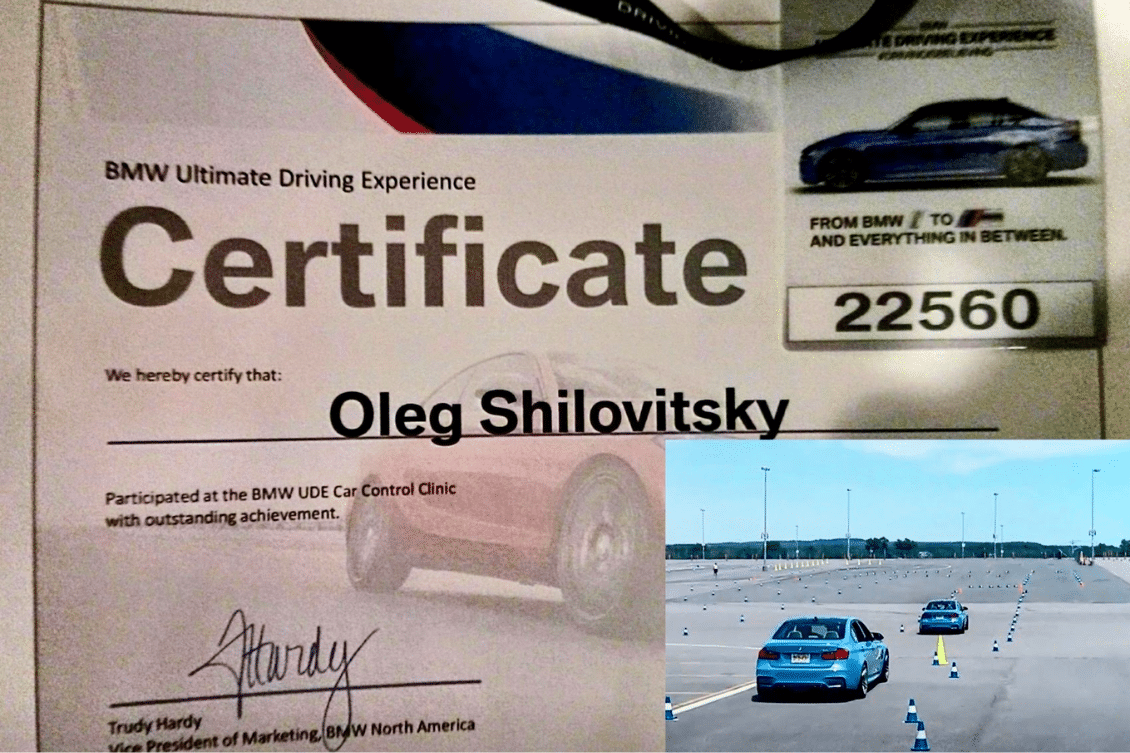

Driving a car is one of the things I like to do. Learning more about driving was always my dream. A few years ago, I took a day course at BMW Driving School where you can get behind the wheel with professional instructors giving you an opportunity to learn how to drive a car to its limits including accelerating, braking, oversteering, understeering, drifting, and more.

My biggest learning aha-moment was about driving strategy, which I found amazingly connecting to my day-to-day practices of PLM implementations.

Today, I want to share my experience of what I learned and compare what I learned during the BMW driving course with best practice recommendations for how to successfully implement the PLM system.

Lesson #1: A car can only do one thing at a time

While the car is a super sophisticated piece of equipment, it can only do one thing at a time efficiently. Your car can (1) accelerate, (2) brake; (3) turn. At the moment of time, you will try to accelerate and turn or turn and brake, and you will lose efficiency.

In my PLM implementation recommendations, I always recommend a company focus on one implementation phase and goal at a time to make it efficient. Decide what problem you want to solve and put all your forces there. For example, you want to focus on how to centralize Item data and create a set of catalogs to classify all items. A great goal, btw. Once you decided to do so, focus on this goal. Don’t try at the same time to bring legacy data from your CAD system and work on setting up your change management process. Do it later. A phased PLM implementation approach is key.

Lesson #2: Raise your eyes and look where you want a car to go

The instructor told me- don’t look at those border cones or g-d forbid at a wall. Believe it or not, your car will end up in the place where your eyes go. Therefore, raise your eyes up and look where you want to go. You will be amazed to realize that car will follow your eyes.

Translating it to PLM language means raising your goals and focusing on the problem you want to solve and where you want to be. For example, if you want to streamline information flow to eliminate manual data re-type, think about it and put in place mechanisms to eliminate manual operations. Thinking about how to improve your Excel routines between CAD drawing and BOM won’t help you. The fundamentals (Excel) are wrong. Focus on goals (automate information flow, single source of truth) and drive your PLM implementation to these goals.

Lesson #3: Push the limits and correct oversteer and understeer

As much as drifting looks cool, it is one of the most inefficient ways of driving, if you want to show results. Therefore, you need to learn how to push the car to its limits but correct oversteer and understeer. Being able to correct yourself during the turning time and pushing the speed up is the most important goal.

The limits of PLM implementation are always a tradeoff and balance between the power of modern technologies and a conservative approach related to organizational change management. Think about this – you push your organization too hard to implement new stuff and you (oversteer) lost the traction. On the other hand, not changing bad processes and not making the organization clean the mess (understeer) will slow you down and won’t help you to maximize the return.

Conclusion

PLM implementation is always a balancing act between introducing a change to your organization and fixing processes and keeping the organization following the same old processes using computers. One of my recommendations, I always say – if you have an organizational mess, don’t bring computers and software. Because you will end up with a “computerized mess”. Focus first on how to change the process, and only then consider bringing in computers and PLM software. The same about technologies – bringing new stuff is great, but only when you set a process for your organization and the PLM system is a way to implement the processes.

At OpenBOM Onboarding Course, we help you to learn about your organization and think how to make the change that will benefit your organization, only after stepping into actual OpenBOM implementation.

REGISTER FOR FREE and check how OpenBOM can help you today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.