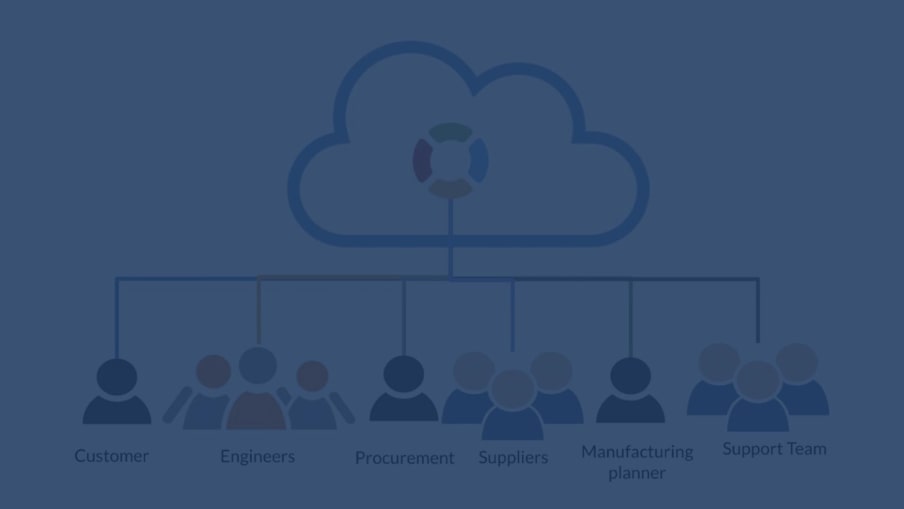

Every manufacturing company or engineering team must decide how to manage one of the most precious things they have – data about the product. And I’m not talking about CAD files only – I’m talking about a complex set of information including data about items, specifications, requirements, 3D models, bill of materials, vendors, purchasing orders, and many others. To have this data not managed in a proper way, can lead to an information disaster, mistakes, lost time, etc. However, to choose what is the right way is not a simple thing too.

Each Company Has Its Own Way To Get Things Done

If you’re part of an engineering team, work for an industrial company, or are involved in any type of manufacturing activity, you know that each team or company has its own way of getting things done. No matter how it is done, things are getting done eventually. In every company, there is a very short period when you can start from scratch – this is a very unique moment, but it is so quick that you almost never feel it. What happens is, usually somebody pulls one of the known patterns of how to get things done and Excel (or spreadsheets) is usually a very popular choice. I’ve seen manufacturing teams start from inheriting the experience of the people that worked in other companies. This event is also happening very quickly, leading to some sort of status quo.

A couple of weeks ago, I had the privilege to be invited to an 808 podcast. It is cool and its duration is exactly 8:08 min. Check out my video. I shared my thoughts about engineers and the biggest challenge for everyone who is trying to sell their products and services to manufacturing companies – status quo.

Speaking to thousands of engineers and manufacturers about data management, PDM, PLM, BOM management and ERP, helped me to understand and to help them to decide about what is the right solution for their problems. Every company has its own setup, specific set of tools, needs, and habits. To change them is hard, but we came to the conclusion why OpenBOM is the best first PLM solution you can find. Here are my 3 “why” below with some explanations.

1- Feels like Excel

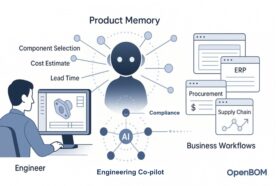

People don’t like to have something new. They want to have something very familiar but done differently. OpenBOM feels like Excel, but it is a cloud-based platform with sophisticated capabilities to manage product data, files, documents, dependencies, etc.

2- Integrated With All CAD Systems

Getting data in a seamless way is paramount. You can overestimate the value of being able to get data from your CAD system in five minutes after you start using the system. OpenBOM “one-click” BOM solution allows you to extract data from your favorite CAD including metadata, files, product structure, visual images, etc.

3- From A Simple BOM to Change Management and POs

Every company that is looking at how to organize their data is afraid to get stuck with a complex process of data extraction, implementation, customization, and many other aspects. Legacy enterprise PLM systems were designed for large companies with established processes and siloed business systems – PDM/PLM, ERP, CRM, etc. OpenBOM provides a unique integrated way to work, which includes many of the highly demanded PDM, PLM, and ERP functionalities combined.

… but that is not all.

One of the biggest values of OpenBOM is the way you can start small and grow up by integrating multiple pieces of functionality and data. It all starts with a FREE 14-day trial where you can explore the service and get support via online support desk and if needed to schedule a web meeting. OpenBOM onboarding training is an exclusive way to help manufacturing companies that are experiencing difficulties to start somewhere…

Conclusion

Start with something familiar. For every engineer, procurement manager, operation worker, the way OpenBOM lays out data (in a way of Excel) is one of the easiest ways to start pulling the organizational data to OpenBOM, step by step. The vertical scale is important. OpenBOM is equally equipped for a single user, a very small team, and larger enterprise companies.

Check out how to start a 14-day Free OpenBOM trial as a next step and contact support to schedule a call with our team.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.