Data is the new oil in the 21st century. The most successful manufacturing companies in the world have realized the importance of data. Understanding and managing the data of a product and its lifecycle is a key element to improving product development and manufacturing process, getting aligned and connected to suppliers, contractors, and other related processes such as procurement and supply chain.

Unfortunately, for many companies today, Excel is still a mainstream tool to manage data. Companies understand there is a better way but the change is hard. This is how data management and digital transformation look for many companies.

As we work with many manufacturing companies, engineers, and contractors, we found that companies really struggle to understand how to move from the state of “Excel mess” to an organized data management process. We helped thousands of companies to organize their processes and data organization by implementing OpenBOM, which provides a super flexible platform to manage data, share information and connect people together.

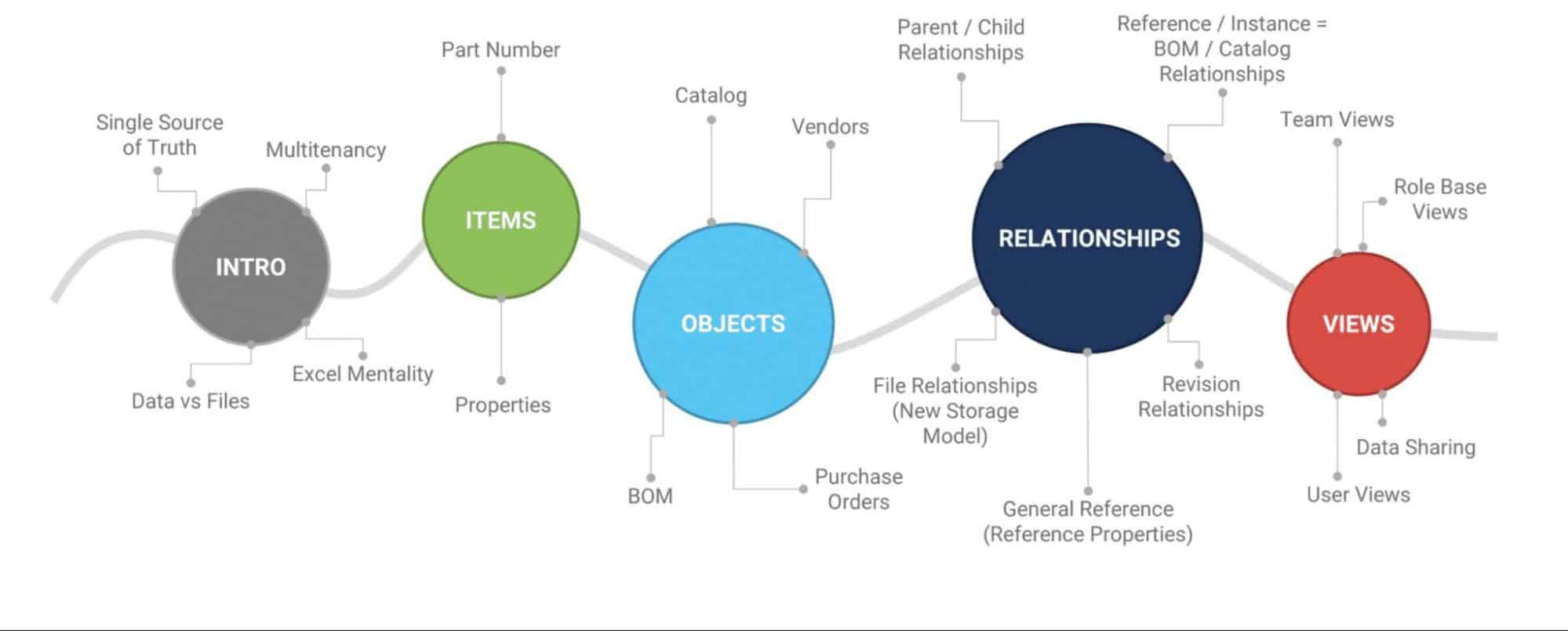

OpenBOM Data Management Basics

Data is the heart of OpenBOM and it is very important to think about data first when you plan OpenBOM implementation. Before moving forward, I recommend you take a minute and check out this free OpenBOM Basic Data management course from the training library.

In my article today, I want to help you organize a framework on how to move from Excel data management to OpenBOM in 4 simple steps.

Step 1: Define Items and Catalogs

This is the most important part of the process as you will be defining a fundamental data element of the product – items. In OpenBOM, an item can be anything – component, standard part, assembly, materials, etc. You manage Items using OpenBOM catalogs, Each catalog has a set of properties (attributes). To get prepared you need to think about all your data and define these Item Types and their attributes. Once you are done, you can create an OpenBOM catalog for each item type.

Step 2: Define BOMs and Templates

While Item is an abstract object that can be used to build products as well as a product itself, the data that actually defines what to include in the product is managed in OpenBOM’s Bill of Materials. BOM represents the recipe, the list of items for each assembly, and sub-assembly. They connect hierarchically. OpenBOM manages these relationships.

To get ready for BOMs, you need to think about what attributes you want to manage in BOMs.The out of the box template coming with OpenBOM defines some typical parameters (eg. Quantity) and a few other attributes that are usually calculated values (eg. Extended cost) that are used to store specific BOM data. Besides that, you can put any parameters there. From our experience, 20% of data is usually in BOM while 80% of data is item data and managed in catalogs.

We recommend creating a simple BOM to check your planning and what attributes to include there. Once you’re done, save it as a template in OpenBOM. Once it is ready you can start creating data using OpenBOM manually and the remaining part is to import the data.

Step 3: Import Existing Data

You should prepare the data for import using the formats described in OpenBOM’s training library. You will be importing data for catalogs and BOMs separately. First, we recommend importing all catalogs and ensuring that everything is saved in the way you want, all attributes are defined and all the data from Excels used to define these items are now imported.

After catalog data import, you can import BOMs. OpenBOM can import multi-level BOMs as well as single-level BOMs. There is no need to have a specific data order- you can do it bottom-up and top-down. OpenBOM will connect it together.

Conclusion

Data migration is a complex process. Do not make the mistake of underestimating the importance and the amount of time you want to spend to manage this process. Define items carefully, organize Excels to import the data, and then import BOM.

Check OpenBOM’s onboarding course – we help you manage this process and will give you advice about what is the best way to organize the data in OpenBOM.

REGISTER FOR FREE to check out how OpenBOM can help.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.