The demand for digital solutions in hardware product development has never been higher. As projects grow in complexity, the traditional methods of managing design files, tracking changes, and coordinating tasks become increasingly cumbersome and prone to errors. The integration of digital tools offers a way to streamline processes, enhance collaboration, and ultimately deliver superior products to the market faster and more efficiently.

In this blog post, we will explore three key benefits of going digital for hardware product development studios. From centralized CAD file management to managing projects, these advantages illustrate how embracing digital transformation can significantly elevate the value and efficiency of your development process.

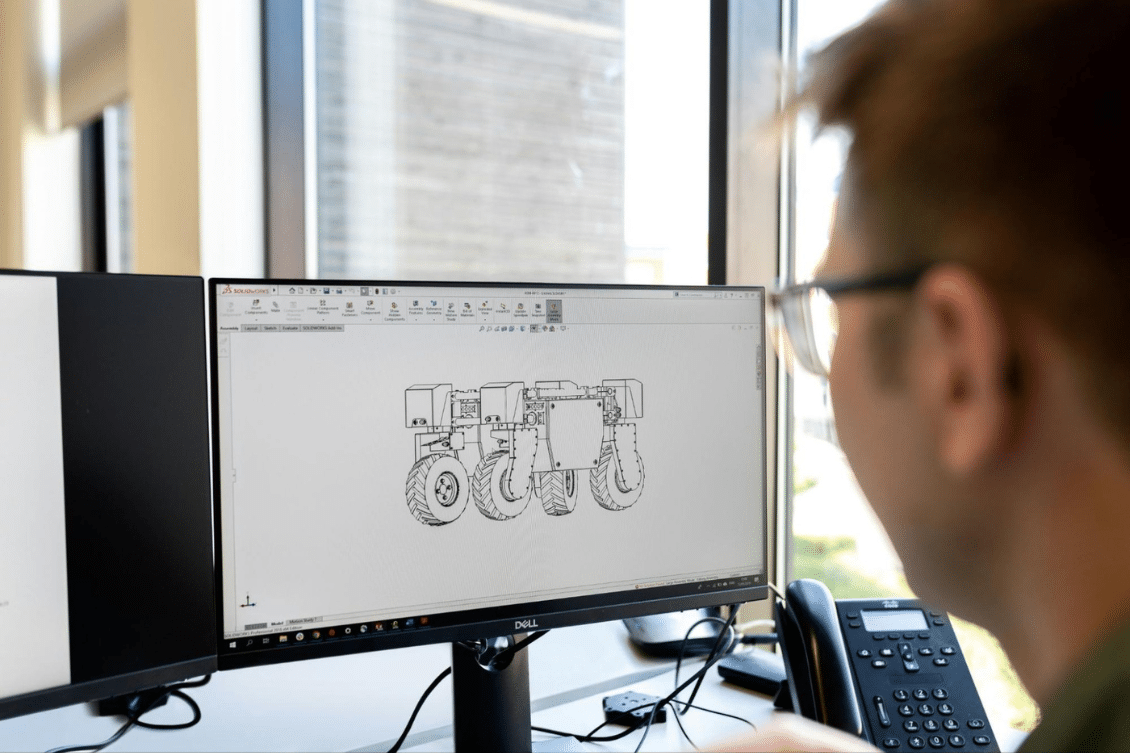

Enhanced Collaboration through Digital CAD Sharing

One of the most significant advantages of going digital in hardware product development is the centralized management of CAD files. Traditional methods often involve multiple copies of files being stored on individual computers or local servers, leading to confusion and version conflicts. Digital platforms solve this issue by providing a single, centralized repository where all CAD files are stored and managed.

With centralized CAD file management, every team member has easy access to the most up-to-date designs from anywhere, at any time. This eliminates the inefficiencies and errors that come from working with outdated versions. Moreover, centralized storage ensures that all changes are tracked systematically, providing a clear history of modifications and the ability to revert to previous versions if necessary. This streamlined approach fosters improved collaboration among team members, as everyone is always on the same page, working with the latest information.

In addition, real-time collaboration accelerates design iterations by facilitating immediate feedback and quick adjustments. Instead of waiting for feedback cycles that can take days or weeks, teams can resolve issues and make decisions on the spot. This rapid iteration process not only enhances the quality of the designs but also significantly reduces the time to market for new products.

Here are the benefits that digital can have for collaboration:

- Easy Access: Team members can access the latest CAD files from anywhere, enhancing flexibility and remote work capabilities.

- Reduced Version Conflicts: Centralized management eliminates the confusion of multiple file versions, ensuring consistency and accuracy.

- Accelerated Design Iterations: Real-time collaboration enables faster feedback and quicker adjustments, speeding up the design process.

- Immediate Feedback: Stakeholders can provide instant feedback, ensuring that any issues are addressed promptly.

- Reduced Time-to-Market: Faster design iterations and decision-making processes lead to shorter development cycles and quicker product launches.

Version & Change Management Control

Digital platforms improve change tracking and version control, essential for the meticulous nature of hardware product development. These systems log every change made to CAD files, maintaining a detailed version history. This ensures that every modification is recorded, providing a comprehensive audit trail.

Version control systems allow teams to easily roll back to previous versions of a design if needed. This capability is invaluable during the iterative design process, where experiments and changes are frequent. Knowing that previous versions are preserved gives teams the confidence to innovate without the fear of losing critical work.

Furthermore, clear audit trails enhance accountability within the team. Each change is tagged with the user’s identity and a timestamp, ensuring that everyone is responsible for their modifications. This transparency not only fosters trust but also helps in identifying and addressing any errors quickly.

Also, change notifications play a vital role in keeping the entire team up-to-date and reducing the chances of miscommunication. When everyone is aware of the latest developments, coordination improves, and the likelihood of errors diminishes. This feature is particularly beneficial in large teams where communication can often become a bottleneck.

By ensuring that all team members are promptly informed of changes, automated notifications enhance overall project coordination. This leads to a more synchronized workflow, where everyone is aware of their responsibilities and the current status of the project.

Here are some benefits that going digital brings to managing versions and changes.

- Easy Rollback to Previous Versions: Teams can revert to earlier versions effortlessly, aiding in troubleshooting and experimentation.

- Clear Audit Trails: Detailed records of every change enhance transparency and accountability.

- Accountability: Knowing who made each change and when helps in maintaining high standards of responsibility.

- Ensures Everyone is Up-to-Date: Immediate notifications keep all team members informed of the latest changes.

- Reduces Miscommunication: Clear and timely updates reduce the risk of misunderstandings and errors.

- Enhances Team Coordination: Improved awareness and communication lead to better coordination and efficiency.

Enhanced Project Management and Workflow Automation

Integrating digital project management tools such as Asana, Jira, or Trello can significantly enhance the efficiency and effectiveness of hardware product development. These platforms provide a centralized hub where all tasks, deadlines, and project milestones can be tracked and managed.

Digital project management tools offer improved project visibility, allowing team members and stakeholders to see the status of tasks and the overall progress of the project in real-time. This transparency ensures that everyone is aware of their responsibilities and deadlines, reducing the risk of tasks falling through the cracks.

Moreover, these tools facilitate better task allocation by allowing project managers to assign tasks based on team members’ strengths and availability. This ensures that work is distributed efficiently and that each team member is working on tasks that match their skills and expertise.

Efficient workflow management is another significant benefit. Digital project management tools streamline processes by integrating with other tools and platforms, enabling seamless transitions between different stages of the project. This integration helps in maintaining a steady workflow, minimizing bottlenecks, and ensuring that the project stays on track.

Automation tools can handle these tasks with precision and speed, freeing up team members to focus on more critical and creative aspects of the project. For example, instead of manually creating BOMs, which can be time-consuming and error-prone, an automated system, like OpenBOM, can generate them instantly. This not only increases efficiency but also ensures that the BOMs are always accurate and up-to-date.

Additionally, automated inventory updates can streamline supply chain management. As parts are used or received, the inventory system can automatically update, providing real-time visibility into stock levels. This helps prevent delays due to stockouts or overordering, ensuring that the right parts are available when needed.

By leveraging workflow automation, hardware product development studios can enhance their operational efficiency, reduce the risk of human error, and allow team members to dedicate more time to innovation and problem-solving.

Here are the benefits going digital can bring to project management:

- Improved Project Visibility: Real-time tracking of tasks and progress ensures everyone is informed and aligned.

- Better Task Allocation: Efficient distribution of tasks based on team members’ skills and availability enhances productivity.

- Efficient Workflow Management: Integrated tools streamline processes and maintain a steady workflow.

Conclusion

Embracing digital transformation is no longer optional—it’s imperative. By integrating digital tools and platforms, development firms can significantly enhance their efficiency, collaboration, and overall project management. From centralized CAD file management and real-time collaboration to comprehensive version control systems and automated workflow processes, the benefits of going digital are manifold.

The advantages we’ve discussed—improved collaboration through digital CAD sharing, robust change tracking and version control, and enhanced project management and workflow automation—demonstrate how digital solutions can elevate the value of a product development studio. These tools not only streamline processes but also foster a more collaborative, accountable, and innovative work environment.

As the industry continues to evolve, the studios that invest in digital transformation will be better positioned to stay ahead of the curve, delivering high-quality products more efficiently and effectively. Now is the time to take the leap and begin your digital transformation journey. By doing so, you can unlock new levels of productivity, innovation, and success in your hardware product development endeavors.

Are you interested to learn more about OpenBOM? Please reach out.

By: Jared Haw

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.