In 2022, manufacturing will be changing and evolving. The assumptions we had a few years ago seem to be no longer valid. As we proceed into 2022, it is important to point out the common pitfalls and what you can do about them.

Not Diversifying your Supply Chain

If there is one thing the pandemic has taught us, it’s to not take anything for granted. This includes your suppliers.

Even if you have 100% faith in your supplier, there are barriers that you can not control that can either make it difficult or impossible to work with them.

The most common reason why companies consolidate into one supplier is for cost savings. You are able to reach economies of scale with one supplier. For example, if you are purchasing 10,00 parts, you will get a better price if you go with one supplier purchasing 10,000, rather than 2 suppliers each providing 5,000. And also, who has time to find backup suppliers? Unfortunately, it’s time to make time.

The pandemic has highlighted certain risks of only having one supplier. Consolidating into one supplier leaves your company vulnerable if that supplier goes out of business or policies change that makes it more expensive to purchase from them.

For each part you procure, you should have a few backups that are ready to receive and place orders if needed. These suppliers should also be in different regions. So, if you are fabricating one part in China, why find another supplier in China? This doesn’t help when certain political policies are in place.

To diversify, look at different regions. Look for suppliers in your home country, re-shoring, or to a country close to yours, near-shoring.

Building the Contract before the Relationship

This one might raise some eyebrows. However, developing your relationship with the supplier, especially an Asian-based supplier is much more important than what’s on a contract. How many people have you heard complain about their manufacturing partner? Of those, how many of those had a contract that was broken? Probably the majority of them. I can also bet that they assumed the contract was more important than their relationship with their supplier.

Simply put, don’t base the potential success of the part or product coming from a supplier off a contract. If you have a great relationship with them, expect to receive collaboration during your manufacturing process. If the relationship is broken, expect last-minute updates, poor communication, and a “deal with it yourself” attitude.

I am not saying that a contract is not important. But, historically, we have seen contracts broken and IP stolen after the lawyers looked at the contracts. A clear contract plus a great relationship with your supplier is the most ideal.

Poor NPI Collaboration

Developing and launching a new product is complex as it is. During a pandemic, an extra layer of complexity was added.

A project with a hundred or so parts brings thousands of tasks. On the development side, you need to properly design, prototype, and source all of the parts. You also need to prepare yourself for mass production by creating the work instructions, assembly instructions, quality requirements, and more.

Open collaboration during the NPI process is extremely important and will lead to a successful product launch. However, there are a few parts that seem to break up collaboration.

A broken change management process:

Depending on the maturity of the development project, you might not have a change management process. If you need to make a change, you make a revision to a part and that’s it. However, as more people become involved, you need governance and control. Meaning, not just anyone can make a change to the part. You need to request a change and then an authorized person can accept the change request.

Having anyone make a change to the product will lead to a number of issues. All of these add up to extra costs and an extended product launch time.

Where inefficiencies and errors start to be shown is when you start to collaborate with your contract manufacturer (CM).

A poor handover from you to your CM:

Your CM will be responsible for making your product. With this, they know best how to make your product efficiently which usually leads to some re-designs. When they start a design for manufacturing and assembly (DFMA) project, there will be multiple changes. Not having the proper change management system in place will create chaos.

This chaos is fueled by the brand questioning their transparency and asking why changes were made when they were not needed, even if the CM found them necessary.

With your CM, you have multiple differences, you have different cultures, different languages, different mentalities, different workflows, and more. With all these differences, you will have proposed changes (requests) that automatically become changes. Thus resulting in errors, financial burdens, and time delays.

From the very start of the process with your CM, objectify the change management process and set rules that can not be broken. This usually means getting away from emailing excels back and forth and moving to a centralized platform.

Not calculating your Landed Costs

Before, if you made a product in China or in Asia, you just assumed that it would be cost-effective. However, recent supply chain trends are impacting your final costs. You have freight costs increasing, tariffs, chip shortages, material inflation, and more.

All of these factors will result in your landed costs being higher than it once was, resulting in thinner margins, or a higher price than your clients might not accept.

There are multiple different ways you can be producing your product. You might contract a CM to fabricate and assemble your entire product. You might also procure the parts and send them to a third-party contract assembler. Or you can procure all the parts and assemble them in-house.

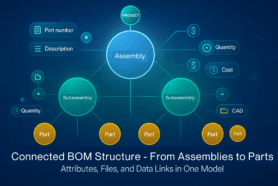

No matter the way manufacture your product, you should review your cost of goods sold (COGS). Break down the BOM, understand the cost of each item, and extend the costs to cover final assembly, quality control, shipping, and tariffs.

Your landed costs are what drive the price of the product you are selling. Perhaps, historically it was based on COGS but freight and tariffs have been shown to be too volatile to ignore.

How OpenBOM Can Help

OpenBOM is a cloud-based platform that manages all of your manufacturing and engineering data. Companies from startups all the way up to fortune 500’s use OpenBOM to replace excels, create a centralized database to bring in, store and share their manufacturing data, and streamline their purchasing & change management processes.

OpenBOM keeps everyone on the same BOM while providing you with the tools to streamline your development to production & scale up operations.

Regards,

Jared Haw

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.