Manufacturing companies use a bill of materials (BOM) to perform multiple analyses and calculations. One of the most typical is raw materials, cost, and weight. I didn’t see a single company that can stay neutral about the optimization of the product cost and asks a question about how much will cost for a specific manufacturing BOM. The finished product, engineering BOM, BOM structure, supply chain, inventory management, material cost – all these disciplines are crucial to understanding the cost. Material cost and labor cost are other examples where In some industries (eg. aerospace), the weight is part of product requirements. Manufacturing companies are continuously looking at how to organize the calculations and keep the efficiency of their work.

The BOM is a list of all the materials and components that are used in a product, as well as the quantity of each component. By calculating the cost of each component, manufacturers can get an accurate estimate of how much it will cost to produce a product.

Is your head spinning from all the OpenBOM calculations? Do you wish you could just see how it all works in a quick video? In this blog post, we’ve created a four-minute video that explains OpenBOM rollups and calculations. You’ll see how OpenBOM calculates part quantities and prices, as well as how to set up your own calculations. After watching this video, you’ll be able to understand OpenBOM’s calculation logic and use it to your advantage!

Why Legacy PLM and Old Excels Are Not Good For Calculations?

The ability to perform the calculations is extremely important, but to be honest, most complex PLM and ERP systems are not so good at this. Their data models are too rigid and they don’t have an easy and flexible way to apply formulas. On contrary, Excels (and other forms of spreadsheets) are good in many sophisticated calculations, but… they are not capable to manage product structure and relationships and, as a result, they cannot help you to perform the calculations that can go between “levels” of product structure.

Many challenges in BOM analytics and calculations are coming from the organization of product development and manufacturing processes. The process of managing the engineering bill of materials, multiple options, components required, identifying parts creating a final product, calculating of production order and many other parameters are important before finished products can be built. Combining data between sub-assemblies is another challenge. Including raw materials is another one. Contract manufacturers are also places where cost calculation can be challenging. Because some of the assemblies are delivered by other vendors.

A simple Excel can calculate a single level BOM, but cannot do much with hierarchical formats and a comprehensive list of all components combined from multiple assemblies. What you using as a BOM list in Excel is good for a demo, but not very useful for comprehensive hierarchical format calculations.

OpenBOM Formulas and Rollups

And this is exactly the place where OpenBOM shines with its flexible data model allowing you to add any attributes and applies formulas to manage a variety of calculations, conditions, and rollups. Here are 5 important things about the OpenBOM Formulas and Calculations model:

- A flexible data model allows using of any attributes. You’re almost as flexible as Excel.

- Product structure data model including Items and BOM.

- Item value calculation can be done in the catalog to support any sophisticated item-related calculations (eg. Item cost, Item weight, etc.)

- BOM calculated value formulas that are applied in BOMs to perform a variety of rollup type calculations (eg. rollup cost from the bottom of the product structure up).

- Rollup conditions allow making exceptions for rollup (eg. very useful for purchased assemblies). It puts a stop to rollup and allows not to perform calculations for a variety of assemblies supplied “as is” – (eg. Purchased assemblies).

OpenBOM Calculation Logical Model

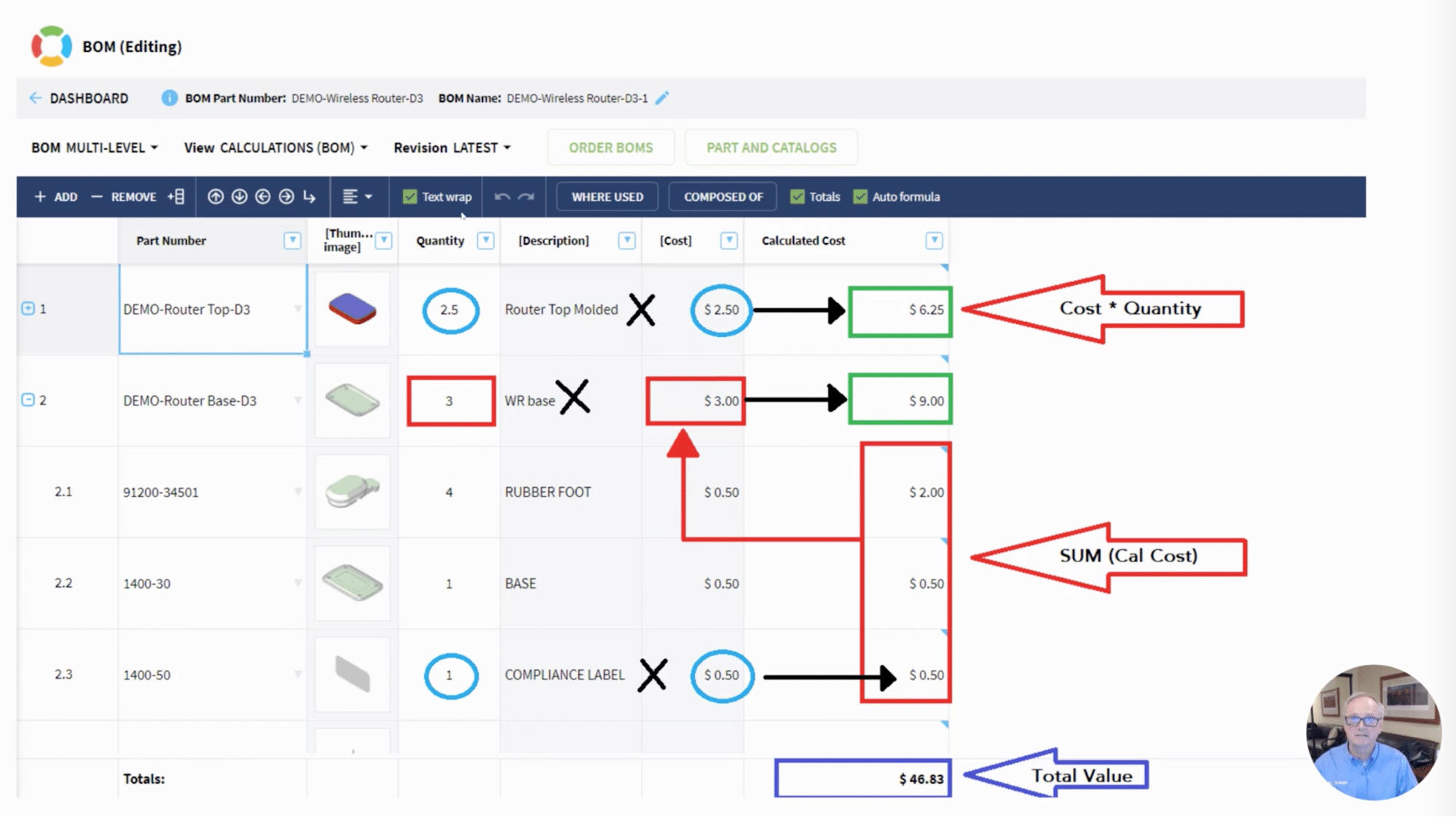

The calculation model is simple, but the following images will help you to understand how it works. In the image below you can see how formulas are evaluated for each line and then used for rollup conditions.

The picture shows you the rollup formula. Each Item [Cost] in that example coming from the catalog can be calculated using a separate formula defined in different catalogs. The only important thing is that each catalog will produce a “Cost” value that can then be used in rollup formulas. This is a very scalable, robust, and flexible mechanism.

Another stronger aspect is OpenBOM CAD add-ins which allow you to extract any data from the CAD system (eg. size, weight) and also use it for calculations and analysis.

Video – 4 min

In the video below you can watch the process of how you can start using formulas for cost rollup. Similar formulas can be done for any other value defined by OpenBOM’s flexible data model. Check the video:

Conclusion

OpenBOM’s simple and powerful mechanism allows performing functions and calculations that are impossible to perform in simple Excel. A short and powerful video can give you an idea of how to start using OpenBOM for calculations. Such formula support will allow for a combination of BOM data management with analysis and calculations – a very simple and powerful concept realized by OpenBOM.

REGISTER FOR FREE to check how OpenBOM can help you today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.