Unfortunately, a few bad apples can spoil the bunch, this saying is true for many areas in life but especially true when it comes to creating a business relationship.

There have been a few bad contract manufacturers (CMs) that have made engineers, product development teams, and companies in general skeptical of partnering with them. So again I stress the importance of vetting and choosing the right supplier because they might become your partner.

Why turn your CM into a Partner?

If you think about it, you wouldn’t hire an engineer with 20 years of experience and tell him/her to sit in the corner, right? So, why would you do this with the CM you hired.

The whole reason for hiring is to bring on people and companies that are smarter than you in something. You hired that marketing firm so they could lead your marketing efforts. You do the same with your CM. If you hired them to make your products and not say anything else then maybe your philosophy is a bit dated.

How to Identify your partner

Just so we’re clear, not all CM’s can or should become your partner, maybe they lack knowledge or proper departments. The Harvard Business Review wrote a fantastic article about how Honda and Toyota set up their manufacturing operations in the US.

New suppliers of both Toyota and Honda were given a list of requirements to meet, such as cost, quality, and delivery. They provided these new suppliers with smaller contracts to test their ability. If they succeeded, they would receive larger contracts and this is how these two automobile giants found their long-term partners.

Now, we all don’t have the resources, volume and time to be testing out multiple different suppliers but we can all do this to a certain degree.

The Steps

Keep in mind that this is not a quick task, nor should it be. Like everything else, a partnership is based on trust that is developed while working together. However, these steps will lead you in the right direction.

Understand how your supplier works:

Not all suppliers are built the same. Understand their specialties and capabilities. For example, if a CM is strong with electronic engineering, don’t ask them to help too much on the mechanical side.

Toyota and Honda will only start a supplier after they understand everything about them. Once you understand your supplier you can collaborate with them in a more beneficial way.

Also, this is a two-way street. Make sure your supplier understands your expectations. If you are honest and forthcoming with them, they will decide whether or not they can support you.

Turn your Supplier into an Opportunity:

Many companies look at their CM as a threat. Maybe this is because they are making similar products or they don’t trust them. If this is the case then you should find a new CM. Why work with someone if you have an uneasy feeling about them?

Successful companies do the exact opposite. Since they understand how their supplier works they are able to figure out ways in which the CM can propose ways in which to improve their processes, optimization, lead time, payment terms, etc…

Turning your supplier into an opportunity rather than a threat is more of a mindset. It takes place after the vetting process. It can also take place after each party understands what is expected from them.

Supervise Your Supplier

Just like managing your team, you don’t want to hand-hold or micromanage but you also don’t want to put it off until your annual meeting. You need to develop metrics to evaluate their overall performance to make sure everything is running smoothly.

Joint Collaboration

Joint collaboration means joint trust. You have all of the foundations built to expand your relationship. Reaching this stage means you understand the capabilities of your CM and understand how they can increase your overall value. They also understand what you expect from them.

This step is by far the most exciting step because your CM will start to get involved in more aspects of your product. You can expect the following:

- Engineering support during development

- More favorable payment terms

- Cost down projects

- Resource investment into your product and company

- And Much More

Choosing the right CM will provide you with multiple opportunities to improve your overall product. There are reasons companies do not trust their CM but I always urge them to look elsewhere if this is the case.

How OpenBOM Can Help:

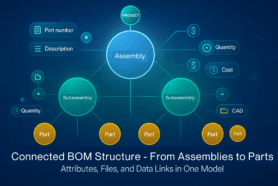

OpenBOM improves the process of how you work with your CM, contractors, colleagues, and other team members. We provide you with the capabilities to seamlessly manage your parts, vendors, bill of materials, purchase orders, and change orders. All BOM, engineering, and manufacturing information are stored in the cloud which you can share with anyone.

Register for FREE to create your OpenBOM account and reach out to us via support @ openbom dot com if you have any questions.

Regards,

Jared Haw

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.