When finalizing your product, it is easy to get overly excited and rush into production. You might have been developing your product for years and are overly eager to start making it. However, there are a number of tasks you must complete before production.

The goal of these tasks and steps between development and production is to ensure you will have a successful product launch.

Depending on your industry, there might be multiple additional tasks to complete, such as applying for certain certificates. However, this list is meant to be industry agnostic. Here are four tasks and steps you must have before starting production in any industry.

Golden Sample

The golden sample is important because it’s the perfect sample that you use as a reference. The golden sample proves you are able to make the perfect product while using mass-produced tools and processes. The main difference between a prototype and the golden sample is that the golden sample uses and follows everything that will be used in mass production. While the prototype uses cost-effective processes.

The golden sample only provides part of the picture though. During production, you can not constantly have all parts made perfectly, there are tolerances. You will have tolerances based on measurements (mm, cm, inches, etc..), colors, textures, and more. To formally objectify this process, you will most likely need to have limit samples, which will complement your golden sample.

Work Instructions (WIs)

During early stage builds and prototypes, there will most likely be an engineer that creates the perfect sample, and it takes time. However, when you transition into production, you will not have this time. Everything will need to be faster and at the same quality level.

Therefore, identifying the steps during production and laying them out is important. The work instructions (WIs) are a set of instructions that the workers and operators must follow. Each step during the fabrication or assembly process is documented so a new worker can easily follow them.

Quality Requirements

Before you start production, you must have an objective quality standard. The quality standard will state what needs to be checked for parts coming in, parts being processed, and final assembly.

With quality standards, defects can often find themselves falling through the cracks, or something you did not expect to cause problems has occurred. You will need to understand how your contract manufacturer (CM) will be able to support you with solving your quality problems.

Regardless, these standards and requirements should be outlined and confirmed with your CM before starting production.

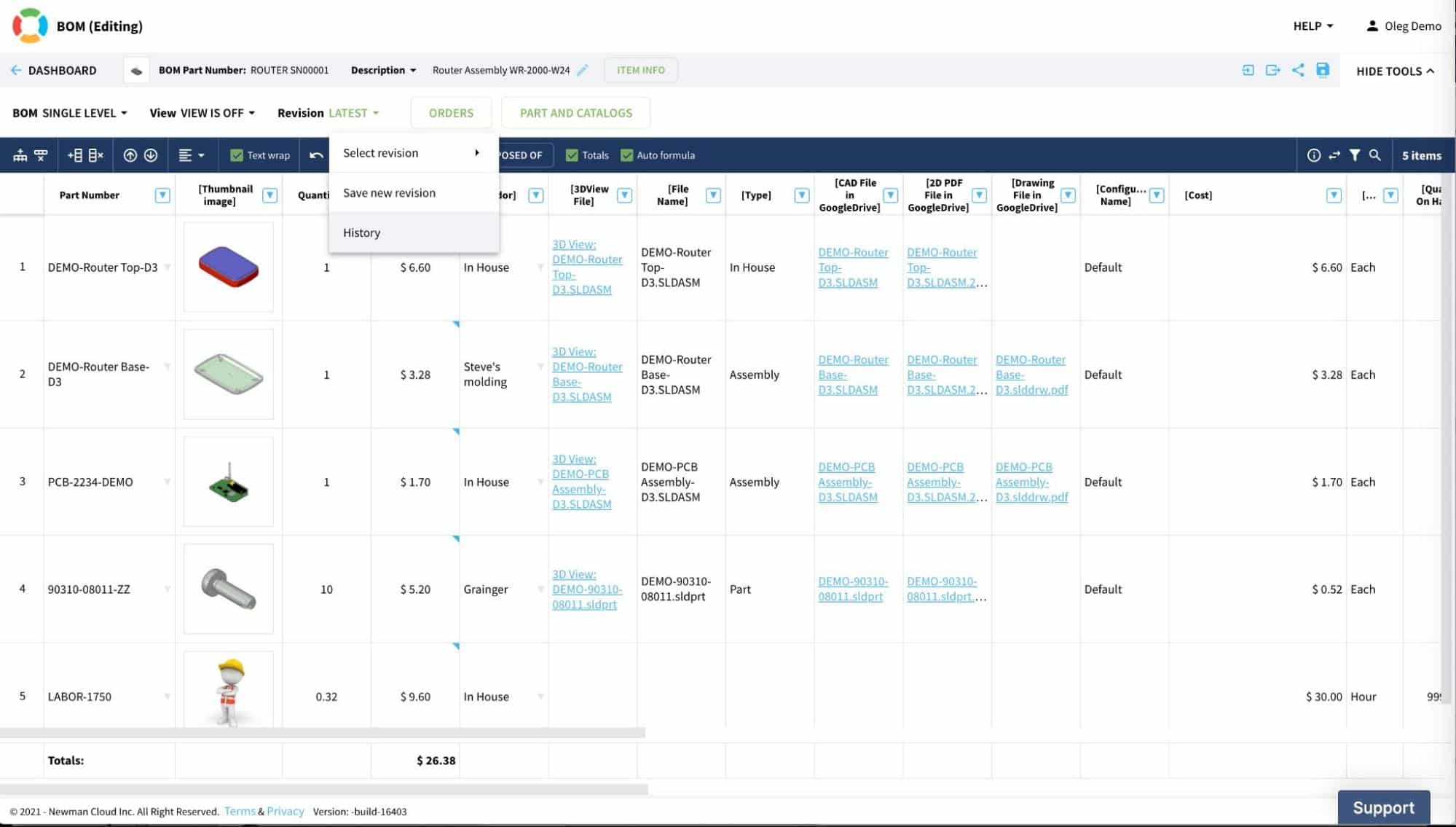

Bill of Materials (BOM)

Defining the BOM before production sounds straightforward. However, manufacturing companies often fail to provide an updated BOM for production. This is usually due to the constant changes not being documented in the BOM. Not having the correct BOM will lead to the following:

- Purchasing or fabricating the wrong parts

- Ordering or fabricating parts with the wrong quantities

- Having the wrong colors, textures, etc…

Before production, you need to confirm the BOM is up-to-date and it’s best to compare the BOM to the golden sample.

What can you do today?

When you are launching your product, there will be multiple revisions and change requests that must be managed. It is easy to lose historical data or fail to share changes with the correct team members. A centralized platform that connects your team, contractors, and suppliers is your solution.

OpenBOM is a cloud-based PDM & PLM platform to manage your engineering and manufacturing data. Companies from startups to Fortune 500’s use OpenBOM to create a centralized database to bring in, store and manage their manufacturing data. With this infrastructure, users also use OpenBOM to streamline both their change management and PO processes.

If you need to improve the way you manage your data and processes, contact us today for a free consultation.

Regards,

Jared Haw

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.