Sales and customers can solve any problem of any business. Manufacturing is not an exception. Design, plan production, order parts, assembly, and sales. In this sequence of activities, to be able to accelerate the outcome is one of the most important processes.

In the world of manufacturing, selling more products and services often comes down to doing a few key things really well: getting to market faster, staying close to your customers, making maintenance easy, and ensuring what you’re building matches exactly what your customers need.

Traditional PLM systems have prioritized engineering workflows, often overlooking the needs of sales and service teams. This engineering-first focus creates silos, limiting alignment with market demands and sales opportunities, and missing chances to drive revenue growth through better product and customer integration. Thinking holistically about product lifecycle and not only focusing on managing CAD files and engineering release can help to grow you manufacturing business. This is why OpenBOM created a unique product combination of PDM, PLM, and ERP functions.

In my article today, I want to show you how OpenBOM can make a big difference for your organization to bring more sales. OpenBOM helps you organize, share, and work with your product data more efficiently. Let’s break it down and look at how OpenBOM can help you sell more by focusing on four important areas:

Getting to Market Faster

In the world of the online economy, customers want to experience the product and learn more about a product’s functions as early as possible.

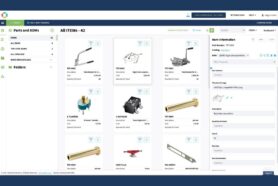

What OpenBOM does is centralize all information in a single and simple way. Getting your product into customers’ hands quickly is critical, and OpenBOM is built to help you do just that.

- Stay in sync: OpenBOM ensures everyone on your team is working with the same up-to-date information, so you avoid costly delays caused by miscommunication or old data. So, when your salespeople speak about the product, they can get easy access to all information remotely. This is what “sales BOM” is about with all features.

- Cut out busywork: OpenBOM automates repetitive tasks like updating Bills of Materials (BOMs) and sharing design changes, giving your team more time to focus on what really matters- innovating and building. It is extremely important for ETO and CTO projects.

- Smooth handoffs: OpenBOM is an element in the overall structure of product information – design, engineering, manufacturing, and maintenance. Handoff this information in the most accurate logic. It connects your CAD, ERP, and other systems so you can move smoothly from design to production without missing a beat. Passing mistakes to ERP will slow the delivery process and lead to delays in product delivery.

When you can get to market faster, you not only sell more but also stand out as a company that delivers.

Building Stronger Customer Relationships

The stronger your connection with your customers, the more likely they’ll buy from you again – and tell others about you. OpenBOM helps you build those relationships by making it easier to meet customer needs.

- Be clear and accurate: OpenBOM makes it simple to share product details that are clear, consistent, and accurate. Customers appreciate when they can get the information they need without confusion. it happens with manuals, product characteristics and other information.

- Customize with ease: Whether it’s tweaking a product for a specific customer or showing them options, OpenBOM’s flexible tools make customization with ease.

- Respond faster: If a customer has feedback or needs a change, OpenBOM helps you track and implement it quickly, showing them that you care and can deliver.

Strong customer relationships mean more repeat business and more trust, which ultimately leads to more sales. Data about the product and all related information can help to communicate with customers and accelerate the business.

Making Maintenance Simple

After the sale, customers want to know that maintaining and supporting your product won’t be a headache.

Companies are moving these days to a service and maintenance mode. In fact, you’re not building hardware and machines, but you’re “renting” these machines and getting more output.

But it comes with a price – the need to manage all maintenance information. OpenBOM product lifecycle twin includes xBOM functionality (DBOM, EBOM, MBOM, SBOM) and it is a foundation for maintenance and operation.

OpenBOM helps you simplify maintenance, so your customers stay happy long after their purchase.

- Organize service data: With OpenBOM, you can keep track of spare parts, service schedules, and product documentation in one place, so your customers (and service teams) can find what they need quickly.

- Help faster: When something needs to order spare parts, OpenBOM makes it easy for your team to access the right data about a specific product right away, cutting downtime and frustration for your customers.

- Keep things current: If your products evolve or improve, OpenBOM ensures everyone has access to the latest information and updates, helping customers stay on top of things.

When maintenance is easy, customers stick around—and are more likely to recommend your product.

Ensuring Your Designs Match Customer Needs

Making sure your designs align with what customers actually want and need is crucial. OpenBOM helps you keep everything on track so there are no surprises (or missed opportunities).

- Track requirements: OpenBOM lets you connect customer requirements to your designs and track them through the entire process, so nothing important slips through the cracks. This is a “requirements BOM” is about.

- Bring teams together: Everyone—whether they’re in engineering, manufacturing, or sales—can work in the same system, making it easier to stay aligned on what’s being built and why.

- Stay on top of changes: OpenBOM keeps a record of changes and updates, so you can confidently manage revisions and make sure everyone’s on the same page.

When your designs match customer needs perfectly, you deliver value—and that’s what drives more sales.

Product Lifecycle Twin and Digital BOM

The foundation of accurate and powerful sales machines, there is a need to get a holistic view of product information for internal and external usage. OpenBOM Product Lifecycle Twin is a foundation of Digital BOM and allows all customers to get up to speed with product information to drive sales of products and services.

Conclusion

OpenBOM creates a digital twin of your product lifecycle, organizing information and streamliining processes across teams, contractors and suppliers.

OpenBOM empowers engineering teams and manufacturing businesses to enhance their product and service sales by streamlining processes, improving data accuracy, and fostering collaboration. In this article, I explored four key ways OpenBOM delivers value and helps drive sales growth effectively.

Selling more products and services isn’t about doing one big thing – it’s about getting a lot of little things right.

OpenBOM helps you speed up your processes, build better relationships, simplify post-sale maintenance, and stay laser-focused on customer requirements.

It’s a simple yet powerful tool that helps you run your business more smoothly, impress your customers, and ultimately sell more. If you’re ready to see what OpenBOM can do for you, give it a try—you might be surprised at how much easier it can make things!

REGISTER FOR FREE and learn more about OpenBOM.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.