If you’re like most engineers, you’ll agree that the faster you can prototype a new design, the better. The rapid prototyping process is a foundation of modern design and manufacturing. Companies are spending tons of resources to make it happen fast. It includes new design techniques, additive manufacturing methods, simulations, and many others. However, there is one thing where prototyping processes go very ugly – data management. One of the biggest challenges is connecting multiple siloed activities such as product development cycle together with connecting design process using computer-aided design (CAD) tools, data sharing including CAD file sharing, custom parts produced, supply chain and to optimize the information flow between all people involved into this process.

This is where OpenBOM comes in – it streamlines the process by providing a single source of truth for parts and Bill of Materials (BOMs). In this blog post, we’ll discuss three ways OpenBOM can help you speed up your prototyping process. Keep reading to learn more!

OpenBOM Basic Features

To streamline the process, OpenBOM provides a set of very unique features as well as a way to streamline the information between all players. Here are 4 groups of basic OpenBOM functions that make it possible.

Multi-Disciplinary Product Structure and Collaboration

The core of OpenBOM is a universal way to manage product structure in the way of a complex data graph model capable to connect together multiple items and BOMs belonging to different product development disciplines- mechanical, electronics, software. OpenBOM makes real-time collaboration process possible with a simultaneous editing process that allows you to restructure modules, assemblies, components together, recombine units designed by multiple engineers, yet keep all this information together, calculating cost rollup and other analytics.

CAD integrations and robust import

Bringing data from multiple data sources is a vital part of the process. Getting BOMs from CAD systems is a pain and when complex design cycles are done by multiple CAD systems and other sources such as Excels and legacy databases, the process can be very complex and prone to errors and other human mistakes. OpenBOM solves it by providing out-of-the-box integrations with all popular CAD systems, as well as Spreadsheets and legacy databases.

Inventory and Order (Planning) BOM

OpenBOM provides integrated inventory management functions that allow you to keep QOH for each item, and build a planning BOM from any assembly (top-down) scaled for the quantity of the order (eg. 100 units). The beauty and simplicity of the process make it easy and fully integrated with production planning and procurement. Everyone relies on OpenBOM to know what parts are needed to be produced, ordered, and assembled.

Purchasing Integrations

Last, but not least is the logical finale – ordering components (both custom and standard) brings the question of how to generate POs to be sent to all contractors and suppliers. OpenBOM automates it by first splitting Order (planning) BOM to multiple vendors and later product POs that will be sent to vendors and control receiving process. Once PO is received, the QOH is updated in OpenBOM catalogs.

How OpenBOM streamlines the fast prototyping processes

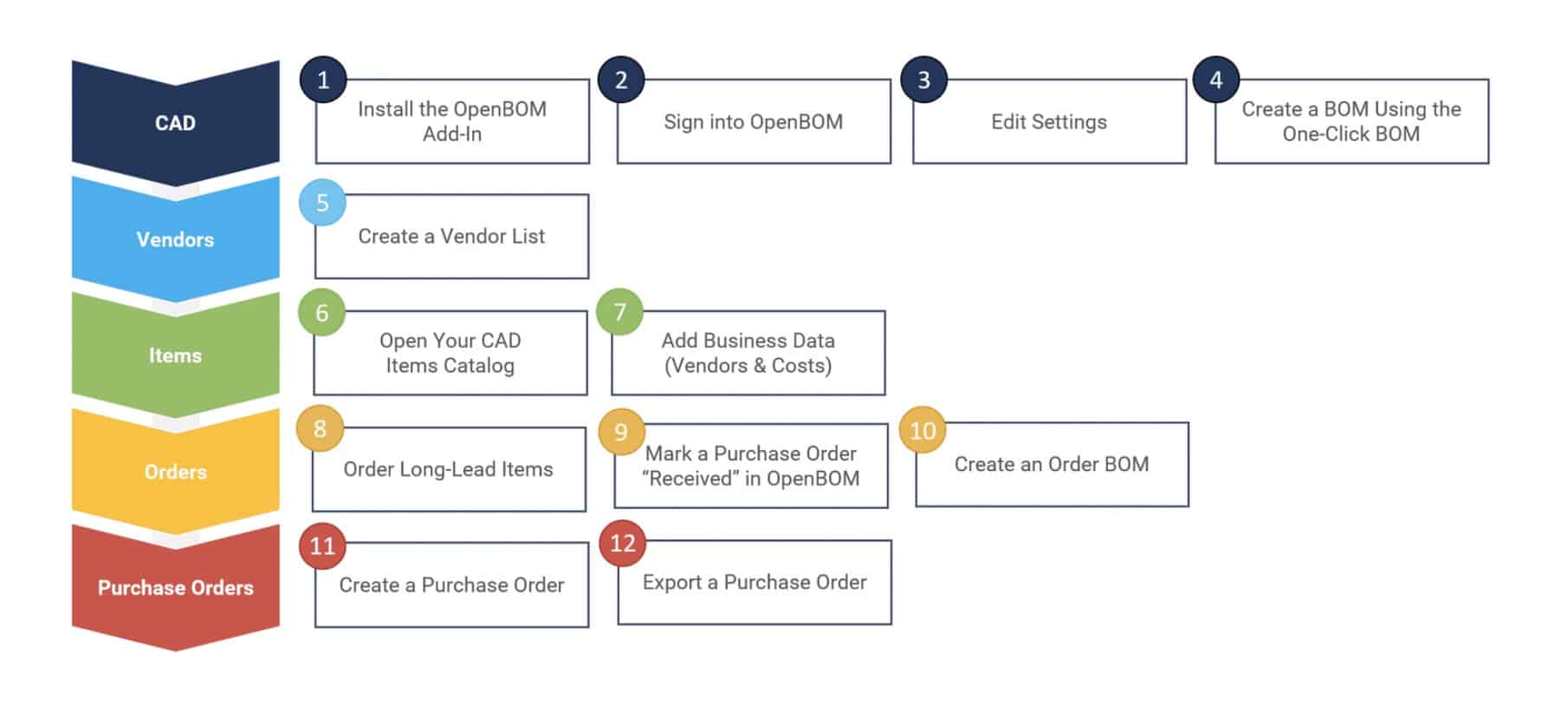

So, how does OpenBOM help to streamline the process? The answer is in the following diagram – end-to-end design to purchase process.

The process provides a fully integrated data management and collaborative stream which connects pieces of information together. Because of simplicity and great integration, companies are spending less time on communication, stop using Excels attached to emails to transfer the data, and put more visibility into the process of transferring engineering to the manufacturing process.

Case Studies – Mechasys and Kuva Systems

Here is an example of how OpenBOM customers are using capabilities described in the article to make product development and prototyping more efficient. In the recent customer story, Cambridge-based Kuva Systems speaks about how OpenBOM drives process improvement.

“OpenBOM quickly produced an accurate and complete Bill of Materials from our CAD models”, says Ethan, “something we had been struggling with our non-integrated Google sheets based process.” Kuva strives to deliver the best value in the continuous methane detection space and has recently increased demands on both internal and external planning and manufacturing. “As we moved into manufacturing, we just didn’t have an accurate BOM with reliable pricing, vendors, and lead times,” says Ethan, “we didn’t know how much our product cost.” According to Ethan, “we started with a complete BOM in OpenBOM, then looked towards costing, forecasting and manufacturing planning.” “The OpenBOM staff coached us on how to set up our inventory management system,” he explains, “helping us decide which CAD properties were important, how to bring them to OpenBOM, and how to extend the item property definition in OpenBOM.”

Another example is Canda-based Mechasys, which is according to the story, streamlines the NPI process using OpenBOM.

“OpenBOM manages our data smartly, with categories and catalogs that align with the way we design and manufacture our product. OpenBOM is literally our Single Source of Truth! FramR has a lot of sub-assemblies and OpenBOM manages and updates them accurately. The OpenBOM catalog item definition is the key to the accurate item and BOM management at Mechasys, we can’t do that with Excel.” Leaving Excel behind has had other benefits at Mechasys. “The company is transitioning from R&D to NPI. We need an accurate, structured BOM to communicate with our supply line and the manufacturing team. OpenBOM gives us just that. We share with internal and external stakeholders, easily exchange BOM data with suppliers, and can deal with a specific sub-assembly easily because OpenBOM naturally divides the BOM into multiple nested levels.”

Conclusion

OpenBOM data management features such as CAD integration, the building of a single source of truth about all components, and the creation of BOM during the early design stage helps to streamline the demand to the procurement process and establish an early BOM baseline for the ordering process.

Unlike traditional siloed processes combining PLM systems with MRP and finance systems, OpenBOM provides a single integrated environment including the design process, information flow between engineers and everyone else involved in the process (production planners, purchasing, contract manufactures and standard parts providers) into a single integrated process. The real differentiation here is how to connect design teams to produce multi-disciplinary product structure, to provide real-time collaboration features connecting people and multiple organizations.

Check out how OpenBOM can help you – REGISTER FOR FREE and start a FREE 14-days TRIAL.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.