If you’re like most people in manufacturing, you probably think of a bill of materials (BOM) as a list of parts used to build something. While that’s true, the BOM is so much more than that! It’s the foundation for everything from pricing and procurement to production and shipping.

At OpenBOM, while working with thousands of engineers and companies we learned that education is one of the biggest lacking points often preventing companies from making progress in the way they can organize the data and their processes. This is one of the reasons we created an extensive Training Library with webinars and make it available online for everyone. Our blog and Youtube channel are also sources of information where you can learn more. OpenBOM also provides an educational free subscription for everyone who needs to learn how to manage the Bill of Materials in their school and college environment.

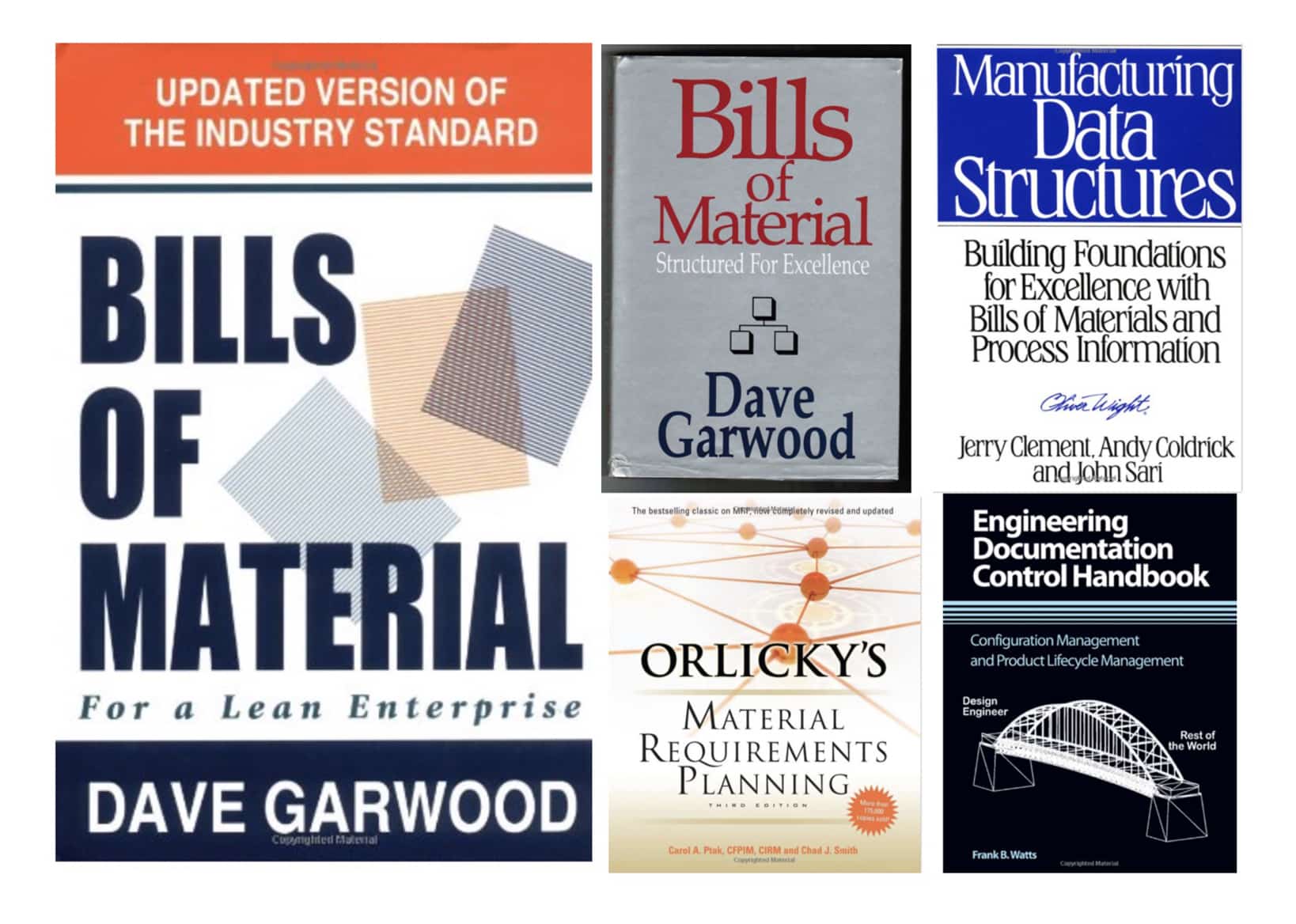

Speaking with many people I found that many people struggle where to start. In my blog today, I want to share with you four books that you can use to start your education about Bil of Materials. This is not a complete reference and I also recommend you follow and read more advanced and new books about technological trends and new development. However, it is important to start from the basics and understand the roots of Bill of Materials, Manufacturing Planning, and CAD data management. If you’re looking to gain a better understanding of the BOM, these five books are a great place to start.

Bill of Materials Structured for Excellence

The book Bill of Materials – Structured For Excellence by Dave Garwood is a classical masterpiece that I recommend you start with. You will learn the basics of material management, data structures, optimization, and how to manage information. The materials from this book were used to teach thousands of companies over the course of more than 15 years. This book took its root at the beginning of CIM (computer integrated manufacturing) and even earlier back in IBM BOMP (Bill of Materials Processes).

Bill of Materials For Lean Enterprise

This is a continuation of the previous book written by Dave Garwood. BOM for Lean Enterprise is a must-read if you want to understand how BOMs are connected to manufacturing processes. My favorite statement from this book is that “your BOM might be correct today, but wrong tomorrow because your business is constantly changing. Want to learn how to manage modern manufacturing companies with the right product structure? This book gives you a basic understanding of how you can optimize manufacturing processes using data management in general and BOM specifically.

Manufacturing Data Structure Foundation

This book was written by Jerry Clement, Andy Coldrick, and John Sari and it is a great piece of reading material that helps you understand the fundamentals of data structures in manufacturing. It starts from defining the manufacturing process, BOMs and routing, speaks about data completeness, and gives you a foundation of NPI processes and custom manufacturing. My favorite part of the book is a comparison between the manufacturing and food businesses. Every restaurant is a manufacturing facility and this comparison gives you a great and easy understanding of every manufacturing process. Check this out.

Orlicky’s Materials Requirements Planning

This book by George Plossi is a classic book about MRP. You should read it if you ever touch anything related to manufacturing to understand how it works and how to manage data and processes, inventory control, business logic, keeping systems up to date, requirements, lots, data inputs, and many others.

Engineering Documentation Control Handbook: CM and PLM

The book is written by Frank Watts. His contribution to engineering change management control processes is indisputable. The book provides a practical guide to the implementation and improvement of Engineering Documentation Control (EDC), Product Lifecycle Management, and Product Configuration Management (CM).

Conclusion

Bill of Materials is not a list of parts in an Excel spreadsheet. It is a much more complex data structure that can help you manage your business and manufacturing processes. Education is absolutely essential in complex disciplines such as PLM, Bill of Materials, Manufacturing planning, and others. Starting from basics will help you understand the fundamentals of the data structures and manufacturing processes. It will also help you to connect to modern digital trends and transformations that are happening these days in the manufacturing industry.

If you want to learn more about OpenBOM then register for free and start a FREE 14 Day Trial.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.