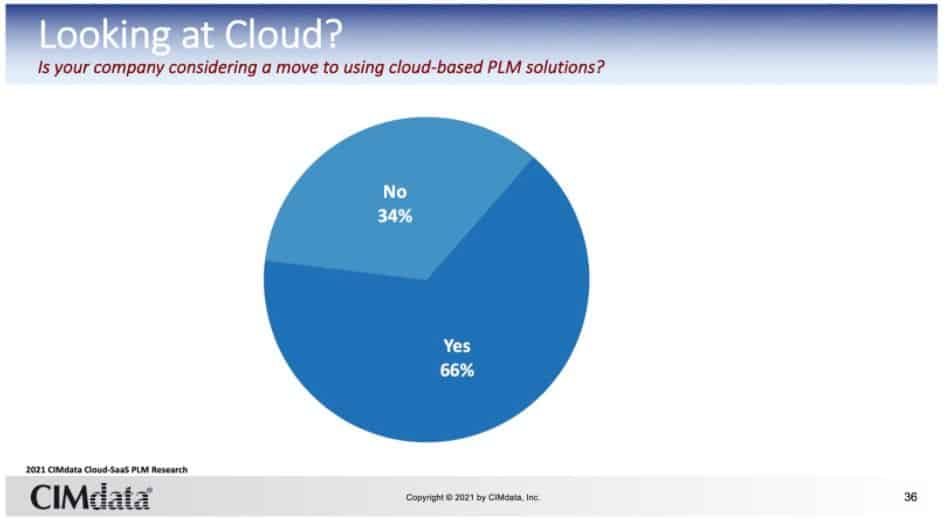

According to the recent research of CIMdata, about 66% of industrial companies participating in their recent study about SaaS PLM are looking for cloud solutions right now.

While that number can seem staggering to some, I’ve got to say I am not one bit surprised.

In this article, I’ll be sharing my insights on why the majority of manufacturing companies are looking for new cloud solutions when it comes to their PLM’s.

PLM is The Last Enterprise Software To Move To Cloud/SaaS

In many leading companies, legacy product lifecycle management (PLM) implementations have been installed on-site with implementation delays, customizations, and challenges to maintain and adapt to changing business requirements.

In smaller companies, PLM is primarily ad-hoc, using Microsoft Excel and shared file services in support of product development. For both, the product development processes are found lacking and unable to support the agility requirements of business today. Many companies are looking to address these requirements using software-as-a-service (SaaS) PLM offerings often delivered using the cloud infrastructure.

This collaborative research program focused on helping answer vital questions about industrial companies’ ongoing and planned Cloud/SaaS-related PLM efforts. The eBook highlights the issues faced by industrial companies looking to make this move and includes sponsor information about how they address these issues, including customer vignettes and links to more information.

Why Cloud/ SaaS?

During my talks with engineers, manufacturing companies, contractors, and suppliers, I usually ask them what is the reason they are looking for cloud software to solve their engineering and manufacturing problems?

I’ve gone ahead and summarized the 5 top reasons that I have received as the leading force to their decision making of bringing a SaaS solution to their workflow.

I decided to share them with you because I think they will help you make the right decision in the process of planning your next steps as a company.

- IT is moving to the cloud: Back in the days when main PLM consumers were large enterprise consumers with a very conservative IT department that was vetting each enterprise software, the current situation was fundamentally different. The last decade of IT development confirmed that IT is moving straight to the cloud. The rationale is very simple. Major IaaS vendors such as Amazon, Microsoft, and Google finally created an awareness that cloud infrastructure is much safer and easier to use than on-premise enterprise data centers. Once AWS and its competitors open the floodgate, companies are moving to IaaS to host an entire infrastructure there. If this is the case, the decision about companies to search for their next PLM solution on the cloud/SaaS is growing.

- Upgrades are too complex and not sustainable: System upgrade and data migration is one of the most important and complex elements of on-premise PLM infrastructure. Companies are scared to be stuck in the legacy system and looking for ways not to get into PLM version lock, not allowing them to move and run on full upgraded platforms. SaaS/Cloud solutions automatically provide a guarantee that a vendor will be taking full responsibility for the update and data change.

- Optimize the cost and PLM investment: Traditional PLM solutions are expensive, require complex installation, implementation, and maintenance. Most of them were developed 20+ years ago and trailed a lot of old technological and implementation practices. SaaS / Cloud-based solution is an alternative to outdated costly systems with dependencies on outdated legacy infrastructure, substantial upfront investment in licenses, installation, and customization.

- Collaboration: The time when companies were located in a single place is gone forever. Modern manufacturing companies are hiring the best engineers they can afford globally, working with contractors and suppliers remotely, and badly need to have tools that can support remote work. In addition to that, COVID-19 became a substantial trigger to speed up manufacturing companies to adopt new collaboration methods to support remote work.

- Ecosystem of other applications: Moving together. This is the current motivation for many companies looking at other applications used in a company. When the majority of new applications are SaaS-based, companies are looking for ways to optimize the infrastructure and information flow using native SaaS approaches.

OpenBOM SaaS Differentiators

At OpenBOM we strongly believe in the value of modern SaaS and cloud technologies. But we go beyond just belief by providing a unique patented real-time collaboration technology to facilitate BOM collaboration and connect manufacturing teams, contractors, and suppliers together.

Here are the main characteristics that make OpenBOM different from many other applications.

- Native Multi-Tenant SaaS provides global access to everyone on the same platform with a unique freemium model and risk-free subscriptions. You can get a FREE 14-Days Trial to test any features and functions in OpenBOM.

- OpenBOM is in continuous ongoing development with frequent updates every 3-4 weeks providing new features and fixes.

- OpenBOM’s unique subscription model provides a flat consumption-based subscription cost that is easy to scale and control for organizational IT. You don’t need to worry about how to supply the software – OpenBOM does it for you.

- OpenBOM patented real-time collaboration combined with a unique streamlined collaborative (a-la Google Doc) user experience, allows your teams, contractors and suppliers to work together and to share the right information at the right time.

- Integrations are on the top of the mind with manufacturing companies when it comes to software adoption. As a native SaaS application, OpenBOM provides REST API, which can simplify the integration with other SaaS applications used in the organization.

Conclusion

The time to move to SaaS and to leverage the power of cloud PLM is now. It was never easier to use the services on demand, import the data and start using SaaS applications right away.

OpenBOM provides a unique approach in data management combined with a simple streamlined user experience and patented real-time collaboration model.

OpenBOM onboarding services gives you all needed support to rethink the way you manage the data in Excels and legacy databases and will help you to move forward.

All together, these features create a strong value proposition for every manufacturing company to start the OpenBOM adoption journey.

REGISTER FOR FREE and start your OpenBOM journey to SaaS immediately.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.