The last 20 months have demonstrated an unprecedented level of disruption and all industrial companies are looking to dig themselves out of the current situation they find themselves in. The following image caught my attention last year and stuck deep in my mind as I was talking to engineers and manufacturing companies for the last months.

I found it interesting to find that almost every company has a very challenging understanding of the long-accepted view of product development organization as well as other lifecycle phases. Everything was disrupted, the development phases were not well defined and supported. Complexities, risks, and opportunities that were downplayed at the beginning were tackled on the factory floors and everywhere in between.

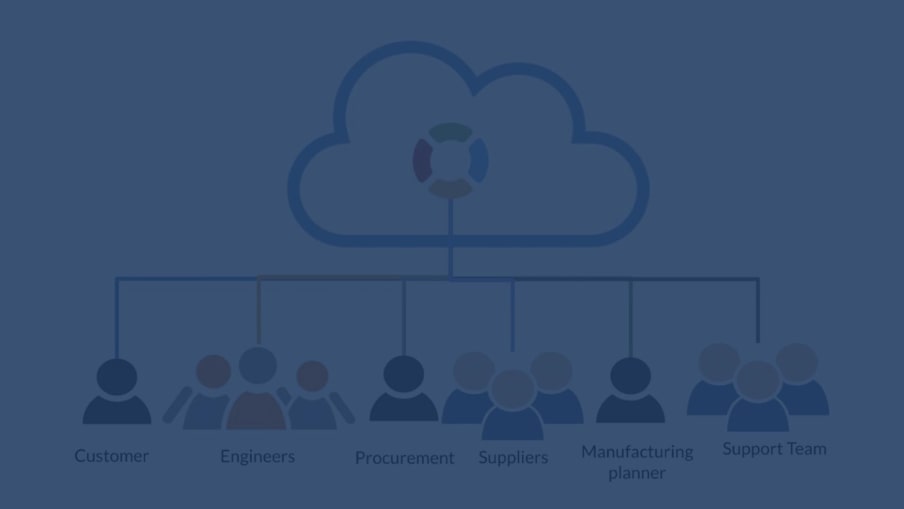

The result of this was a massive sudden change that went through all stages of the development, operation, projects, and the high demand in speeding up all processes and activities. The question about how digital transformation can make a difference to companies was merged together with the new realities most manufacturers are experiencing these days. However, what was the key element of this sudden change is the highest possible demand for information that can be obtained in every level and every state of the company development.

I came across 5 distinct changes in the manufacturing industry that fundamentally changed the behavior and the way these companies are operating, developing, manufacturing, and supporting products. Here is my list and some comments about it.

Manufacturing companies are becoming software companies

There is big news in every manufacturing company these days. They are fast transforming from companies developing products (metal, plastic, or even electronica) to companies that are developing software. It changes many of their views and beliefs on how they should develop their products and operate.

Products are becoming services

This is the second big change after moving away from just product development and selling these products. Companies are changing and now developing services. Think about mileage instead of tires, think about hours of flight instead of airplane turbines and think about electricity service instead of generators producing it. The changes are so fundamental that it requires re-thinking of everything you do and especially how to manage product development and lifecycle processes.

Connected products are everywhere

Another interesting aspect of the change is related to connected products. Everything is not connected. Similar to how we connect with our families, friends and peers, we can see products (or services) are becoming more and more connected. Products are providing information about what happens with them and this information is quickly becoming a critical part of the delivery of the new services.

Companies are selling services

Selling services transforms the fundamentals of how everything is sold. What was important before is to sell a product, now it is a question of how to operate it every day and how to keep customers happy on an everyday basis. The sales process switched from selling a product and then managing the customers very much in the subscription payments. All together it changes the state of mind.

Customer experience rules everything

An immediate outcome of the changes related to selling services to customer support is the switch of the priority on how to deal with customers. What was known as a sell and move on the new prospect behavior has now changed to be a focus on the customer experience.

What is my conclusion?

This is the time of change for many manufacturing companies and these changes will impact the way PLM vendors are developing the products and selling them. PLM must become more adaptable to new industrial companies’ behaviors, new business models, and new software delivering methods to support new manufacturing activities and adaptations to new normals. It is an interesting time for PLM vendors to be in. PLM software vendors will have to adapt to the new demands and realities of manufacturing companies. The vendors who will do it will be moving forward. The others will stay in the past.

Want to check out how OpenBOM can help you? You can REGISTER for FREE, check out our product tour page, register, and start the free trial today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.