If you’re like most manufacturers, your bill of materials (BOM) is probably a mess. It’s likely scattered across multiple Excel files, and it’s difficult to keep track of changes and revisions. What’s more, if you need to make any changes to your BOM, you have to tediously go through each Excel file and update them all manually. This process can be time-consuming and frustrating, especially if you’re working on a tight deadline.

Why Excel Is Easy To Start?

Excel is a first go solution for every engineer or company to manage the Bill of Materials. History is the root cause for all the mistakes engineers and manufacturing companies do when they pick this choice. Here are 3 reasons why companies slip into Excel data management.

- Existing CAD exports are using Excel

- Flexible to add any data

- Clear ownership and zero $$$ to start

You cannot blame engineers and manufacturing companies for making this decision. Most of them, don’t want to think about data management and they think that their business is not big enough, the problems are not that painful and, after all, this is not their responsibility to think about data management. After all, blaming IT was a good strategy for the absence of reliable data management and mistakes done by generations of engineers and manufacturing companies.

Spreadsheets Are Super Costly Down To The Road

While spreadsheets are easy to start, Excel (or any other spreadsheet) is a fundamental barrier to operational efficiency in any engineering team and manufacturing company. Talking to thousands of engineers and manufacturers we learn about 5 top inefficiencies you will be facing when using spreadsheets to manage product information.

- Data copied in multiple spreadsheets leads to no single source of truth.

- No way to manage structures and dependencies and files

- No way to make calculations such as rollups and others

- No way to manage multiple revisions of structure data

- No way to securely share data between multiple users and teams

Here are a few quotes for OpenBOM customers about problems they faced by managing product data using Excel.

“Trying to manage a product evolution in Excel gave me nightmares,” says Senior Mechanical Engineer David Rubli at Fize Medical. “We quickly realized we needed a solution that fit our needs.”

Thunderbasin Engineering was tired of managing complex design projects using Excel.

“I was absolutely tired of using Excel to manage bills of material”, Excel was just not up to the task of managing my customer’s increasingly complex data”.

“I use Solidworks, Altium, Autodesk Fusion 360 and Eagle, Excel, Google docs, and many others. No single cad platform or spreadsheet holds all my information and OpenBOM connects them all” says Paul Blaylock of Blaylock LLC.

OpenBOM is Like Excel, But Better…

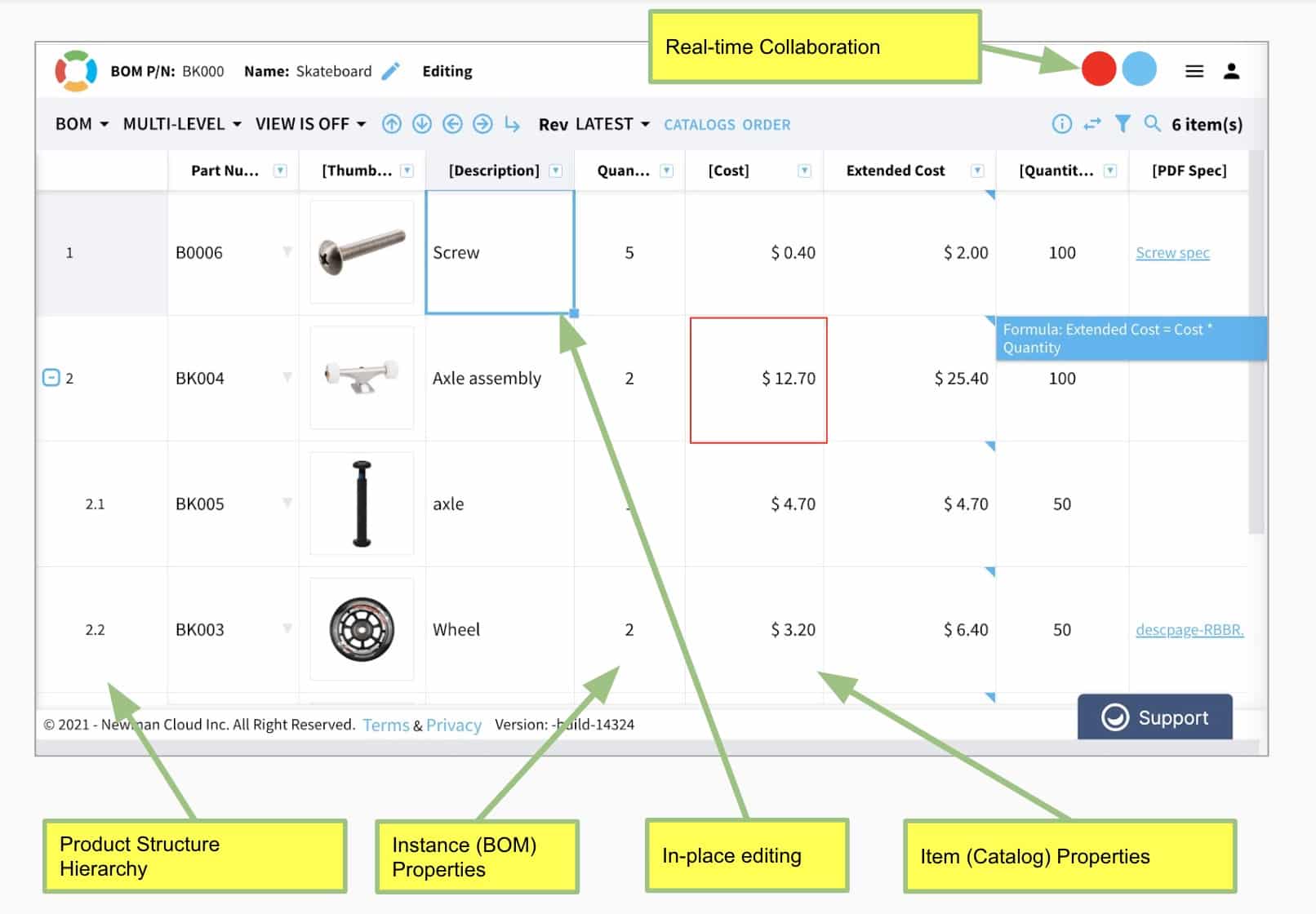

Luckily, there is a better way. And this is what OpenBOM does with our patented BOM collaboration SaaS platform and SaaS BOM service capable of easily managing your BOMs online, making it easy to keep track of changes and revisions. What’s more, this service can help you improve efficiency and reduce costs in your manufacturing process.

OpenBOM gives you super flexible data management like Excel, to support global access and instant real-time collaboration like Google Spreadsheet, but at the same time, provides you with everything you would need to manage product data

- Item Management and Revisions Control

- Structured BOM

- Automatic rollups and calculations

- Team collaboration and change approvals

- Seamless integrations with CAD systems.

Conclusion

OpenBOM gives you all the advantages of Excel and spreadsheets but delivers it as a scalable data management solution available globally that supports manufacturing companies of every scale.

As one of the OpenBOM customers, FlyPyka said, our airplanes have lots of parts and assemblies to keep track of across two distinct teams, Engineering and Manufacturing, and we need to be on the same BOM all of the time. Getting all of that info straight was a big problem and Google sheets weren’t going to get us there. We were basically trying to build OpenBOM in Google sheets.” After a bit of research, OpenBOM for Teams was a perfect fit for this rapidly growing company.

REGISTER FOR FREE and check out how OpenBOM can help you today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.