Manufacturers are always looking for ways to streamline their operations, reduce costs, and gain a competitive advantage over their competitors. A manufacturing strategy that is often used to help manufacturers launch products faster, reduce costs, and gain a competitive advantage is leveraging the skills and experience of a contract manufacturer (CM).

While partnering with CM’s is not a new concept it’s been proven challenging to do. Especially with COVID, supply chain disruptions, and political tensions, which have made manufacturers pivot their manufacturing strategies in the last 4 years.

However, by following the correct processes, you can leverage the services of CMs and gain the competitive edge your company desires. In this blog, we will go over the 5 steps you need to take in order to partner with your CM and the long-term benefits this partnership will bring.

What is Contract Manufacturing

Before we go into the steps to partner with a CM, let’s first focus on what a CM is. A CM is a company a manufacturer hires to build their product. The CM might not have all of the production lines in-house to make each part and component but they have a supply chain network to source all parts they can’t fabricate in-house.

The main reason why companies hire a CM is so they can focus on what they do best and they let the CM focus on what they do best. Think of why Apple outsources production to Foxconn. Apple has more than enough money to invest in its own facilities but has decided for years to leverage a company to build its products.

Here are the top reasons a Manufacturer partners with a CM:

- Cost Savings – The manufacturer does not need to invest in the production lines to build their own products.

- Expertise and Specialization – CMs typically have specialized knowledge and experience in specific industries.

- Scalability and flexibility – CMs can adjust production volumes to meet your demands.

- Focus on Core Competencies – Outsourcing manufacturing allows your businesses to concentrate on their core competencies, such as product engineering, marketing, and distribution.

5 Steps to Partner with a CM

Like anything else, there is a process to achieve a goal. For this goal, it is forming a successful partnership with a CM that will last years to come and help your company gain a competitive advantage.

Here are the 5 steps to partner with your CM.

Step 1: Define Your Objectives and Requirements

Before you even begin searching for a suitable CM, it’s important to have a clear understanding of what you aim to achieve through this partnership. This initial step sets the foundation for the entire collaboration and shapes your approach toward selecting the right CM.

Here’s a breakdown of this first step.

- Identify Your Goals

- Define Product Requirements

- Set Budget and Cost Expectations

- Establish a Timeline

- Assess Scalability Needs

- Align Values and Culture

While not as quantifiable as other objectives, cultural alignment and shared values can significantly impact the success of a partnership. Consider whether the CM’s values and approach to business align with your own, as this can enable smoother collaboration.

Step 2: Search Suitable CMs

With a clear understanding of your objectives and requirements, it’s time to evaluate multiple CMs. This step involves evaluating, research, assessment, and decision-making. Here’s a list of what you plan to accomplish in the second step:

- Comprehensive Research

- Evaluation Criteria

- Develop a Set of Criteria for Evaluating and Comparing CMs

- Request Proposals and Quotes

- Seek References

Step 3: Due Diligence and Site Visits

As you progress to find the ideal CM for your partnership, it’s essential to conduct thorough due diligence and site visits. This step allows you to verify the suitability of potential CMs and gain a deeper understanding of their capabilities and practices. Here’s how to navigate this critical phase:

- Verify Financial Stability

- Certifications and Compliance

- Quality Control and Assurance

- Regulatory Compliance

- Site Visits

- Assess Communication

- Analyze Capacity and Lead Times

- Review Intellectual Property Considerations

During site visits and discussions, consider whether there is potential for collaboration between your organization and the CM. By conducting thorough due diligence and site visits, you gain confidence in your chosen CM’s capabilities and practices.

This step not only validates your decision but also lays the groundwork for a productive and successful partnership. It ensures that both parties are well-informed and aligned as you move forward in the partnership process.

Step 4: Negotiate Terms and Sign Contracts

With a suitable CM identified and due diligence completed, it’s time to formalize your partnership through negotiations and the signing of contracts. This step is pivotal in establishing clear expectations, responsibilities, and safeguards for both parties involved. Here’s how to navigate this critical phase:

- Preliminary Discussions

- Engage Legal Expertise

- Essential Contract Components

- Pricing and Cost Structure

- Intellectual Property Protection

- Quality Control and Assurance

- Communication Channels

- Review and Approval

- Signing and Implementation

By negotiating terms and signing contracts, you formalize the partnership with your chosen CM. This phase is essential for establishing clear expectations, protecting your interests, and ensuring that both parties are aligned in their commitment to the partnership’s success. Effective contract management sets the stage for a productive and mutually beneficial relationship throughout the duration of the partnership.

Step 5: Establish Effective Communication and Collaboration

Having negotiated and signed a partnership contract with your chosen CM, the next phase is to establish seamless communication and collaboration. Effective interaction and teamwork between your organization and the CM are fundamental to the success of the partnership. Here’s how to navigate this phase:

- Communication Protocols

- Regular Meetings

- Shared Goals and Objectives

- Collaborative Product Development

- Quality Assurance

- Set Key Performance Indicators (KPIs)

- Continuous Improvement Initiatives

By establishing effective communication and collaboration practices, you enhance the efficiency, quality, and overall success of your partnership with the Contract Manufacturer. Regular and open dialogue, a commitment to shared goals, and a focus on continuous improvement contribute to a productive and harmonious relationship that can thrive in the dynamic world of manufacturing.

Steps to Take Today

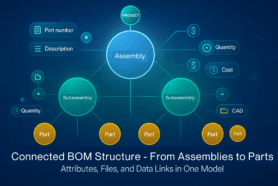

Everything starts with your data and the quality of your data. If you have broken data then you’ll have a broken system. Before you start evaluating CMs you’ll need to make sure your data is all in order for a smooth transition to your CM. This is what OpenBOM provides you.

OpenBOM is a cloud-based PDM & PLM platform to manage your engineering and manufacturing data. Companies from startups to Fortune 500s use OpenBOM to create a centralized database to bring in, store, and manage their manufacturing data. With this infrastructure, users also use OpenBOM to streamline both their change management and PO processes.

If you need to improve the way you manage your data and processes, share data instantly, or collaborate with contractors and suppliers, contact us today for a free consultation.

Regards,

Jared Haw

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.