SOLIDWORKS is one of the most popular 3D MCAD software packages on the market. It has revolutionized the CAD market by bringing a professional MCAD tool to the Windows platform. For years it was the first choice for many mechanical engineers, it’s a powerful program that can do a lot.

However, SOLIDWORKS was born back in a time when USB drives and floppy discs were more popular than the Internet and companies were not concerned about digital transformation and establishing digital workflows between designers, manufacturing contractors, and suppliers.

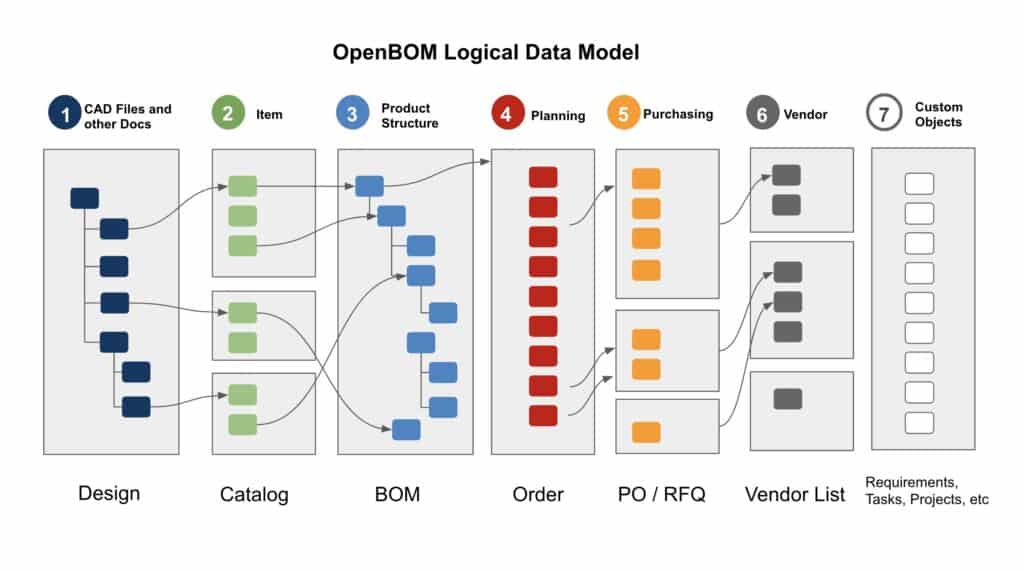

These days products are getting more complex, including not only mechanical, but also electronics, PCB, and software components, Design contractors, and contract manufacturing is growing and becoming an inseparable part of the product development process and production planning.

OpenBOM for SOLIDWORKS – Expanding Digital Workflows

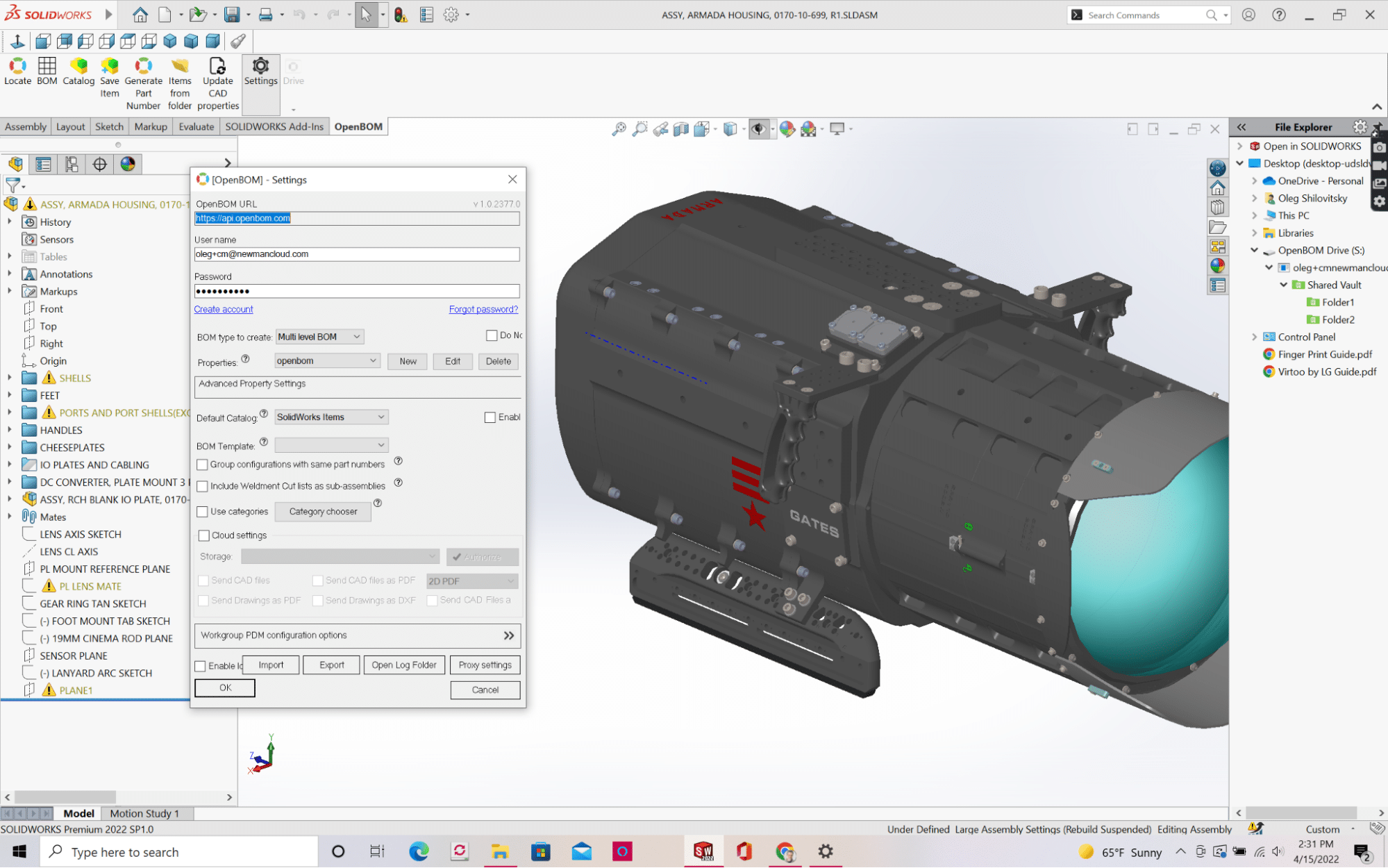

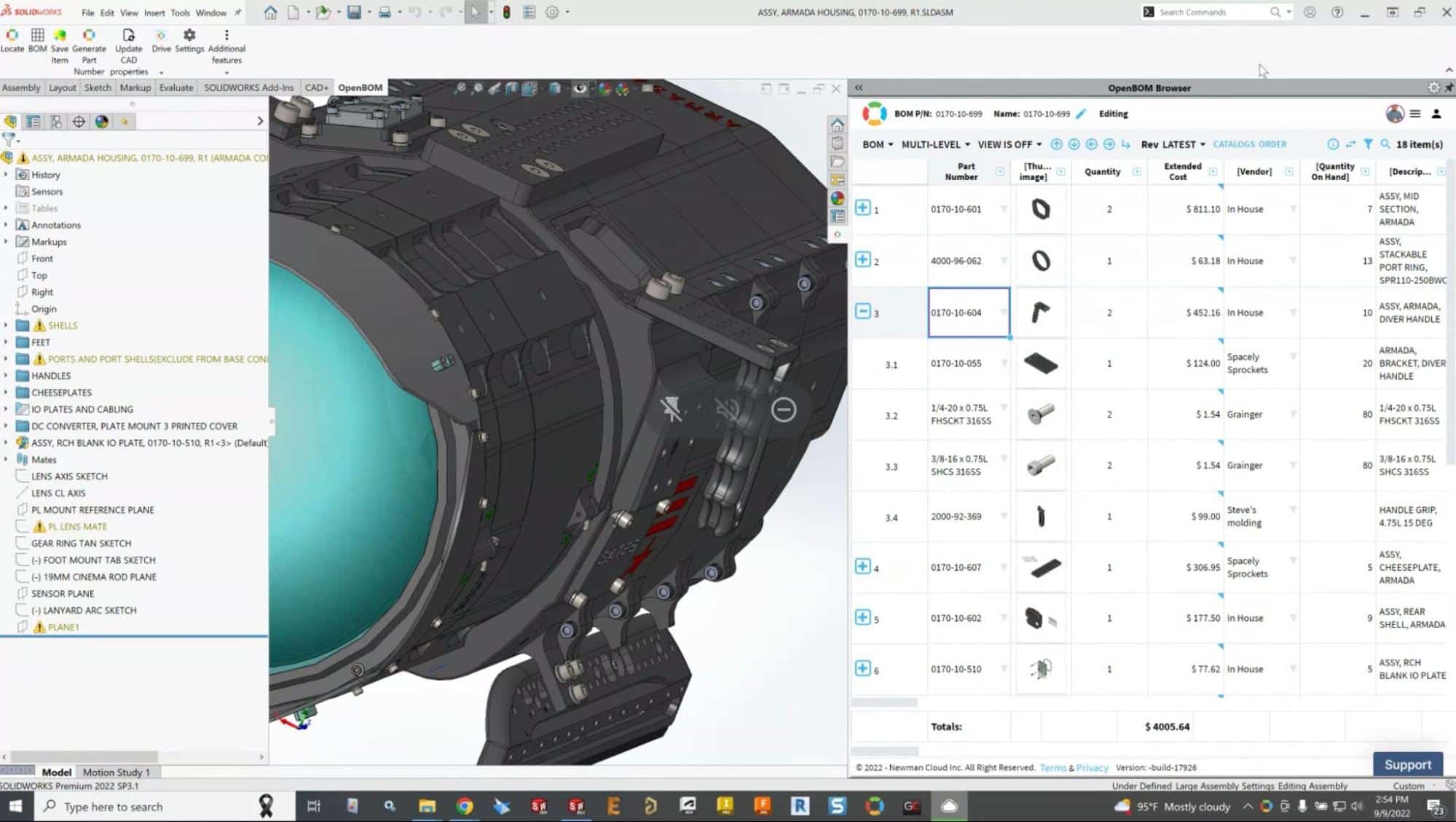

To deal with such a growing level of complexity and communication you need to complement SOLIDWORKS with an online tool and technologies that can help to manage data in a digital form beyond a traditional CAD system’s features and functions. Let’s start by saying that OpenBOM is fully integrated into traditional SOLIDWORKS system and user experience.

OpenBOM for SOLIDWORKS is a tool that can help engineers and manufacturing companies to expand the SOLIDWORKS CAD system with additional capabilities to manage SOLIDWORKS CAD files, bills of materials, and to improve data management beyond the design process, to connect engineering, manufacturing, and procurement teams.

If you’re a SOLIDWORKS user, looking for ways to improve your workflow and digitally transform your processes you should try OpenBOM. In this blog post, we’ll share five things you should try with OpenBOM – an online PDM and PLM tool that manages bill of materials (BOM), integrates seamlessly with SOLIDWORKS, and helps you digitally transform the downstream processes. Whether you’re new to OpenBOM or just looking for some new tips, read on for some helpful advice!

5 Things SolidWorks Users Must Try With OpenBOM

Here are the top five things that can change the way you think about the Bill of Materials and overall information workflow.

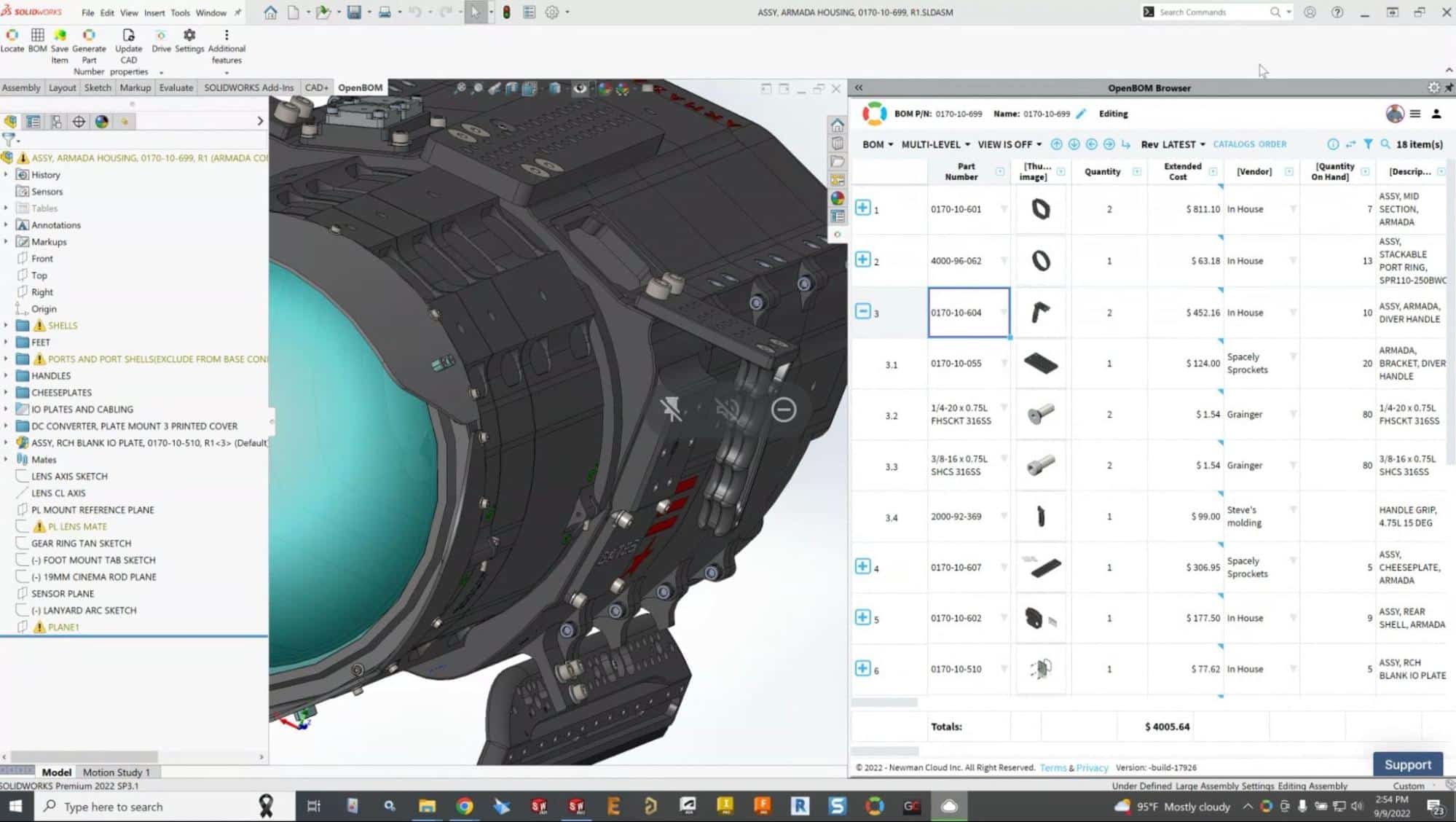

One-Click BOM for SOLIDWORKS

Don’t make it think. OpenBOM environment is easy and simple to start with. And this is my favorite thing because it is easy and simple. You can register for OpenBOM, start a free trial, install Solidworks Add-in, configure your account, (hint: don’t pick the most complex one – it is easier to test), and click on the “BOM” command. The total experience will be about 15-20 min. You can watch videos here.

OpenBOM’s flexible data management environment allows you to capture the data automatically, and generate a full Bill of materials with all information that can be shared instantly with anyone you need or exported to Excel, CSV, PDF, or Zip format.

Automatic Part Number Generation

Managing Part Numbers is a huge pain. OpenBOM gives you a flexible way to automate this process for any individual part or an entire assembly. Check the following video for more details.

Merge Bill of Materials for multiple assemblies

This feature is an absolute killer. Imagine you develop some equipment and the design is in multiple Solidworks assemblies. Working with many Solidworks customers I found it to be a very typical use case. However, you need to produce a single BOM for your machine or equipment. You won’t solve the problem by exporting BOM into Excel from each SolidWorks assembly. Combining BOMs in Excel is a nightmare. OpenBOM will do it with a single click using the OpenBOM Flattened BOM feature.

Automatic Cost (and others) Rollup

I didn’t see any manufacturing company that will stay neutral to the ability to automatically create a cost rollup in multi-level cost rollup based on the data imported from the finance or ERP environment. It is a priceless function and it can save you a ton of time. Check the following documentation page in OpenBOM Training Library to learn more about the rollup function.

Automatic upload of files to the cloud and OpenBOM ZIP export

Another winning feature that has been asked for by practically every customer – the ability to export data and files in a single zip package. OpenBOM allows you to automatically upload any files when generating BOM from SolidWorks – native CAD files, STEP, PDF, DXF, and other files. Once it is in the cloud a single click of the Export button will create a zip package that includes a BOM and all files attached to BOM items. Watch the following video for more details.

What SolidWorks Customers Are Saying about OpenBOM

There is no better way to learn about OpenBOM than to read customer stories and G2 customer reviews. There are hundreds of stories and reviews – I highly recommend you check them out. Here are a few of Solidworks customer quotes about the value of the usage of OpenBOM in the Solidworks environment.

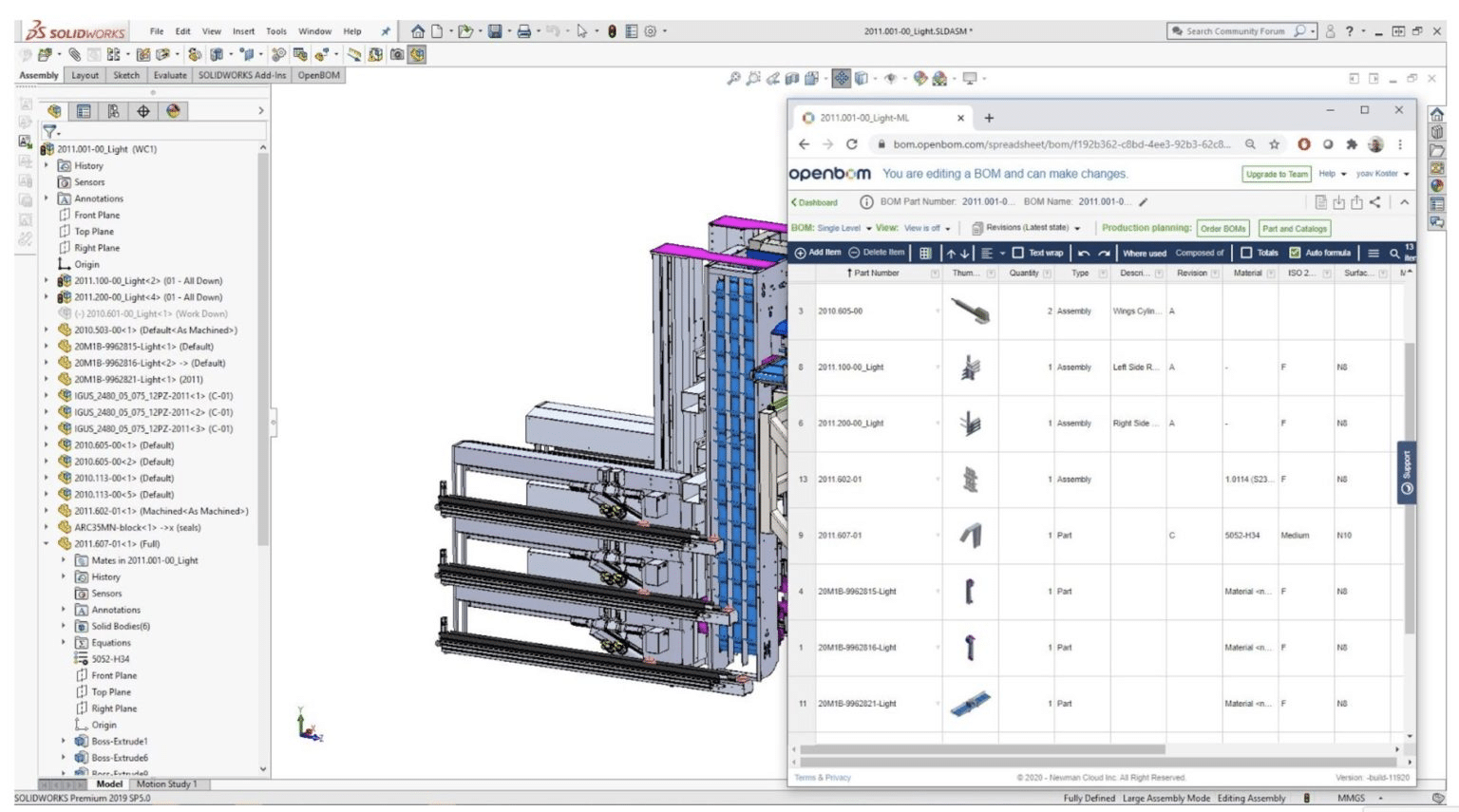

“One of his favorite things about OpenBOM is CAD integration. Every time we extract the BOM from SolidWorks using Excel you have extra work to do to get it right (worse with large assy or sub-assy). With OpenBOM the update just happens when you click the button.” – says FF Robotics co-founder and VP of engineering, Yoav Koster. “Something we didn’t anticipate was the ease of sharing the BOM with the rest of our team. We have a property for Make or Buy which we set in the Catalog. FF Robotics purchasing department gets the BOM and knows exactly what to do. We could have done it before but it demanded more work and sometimes it just didn’t get done or we made some mistakes.” Read the full story about OpenBOM and FF Robotics here.

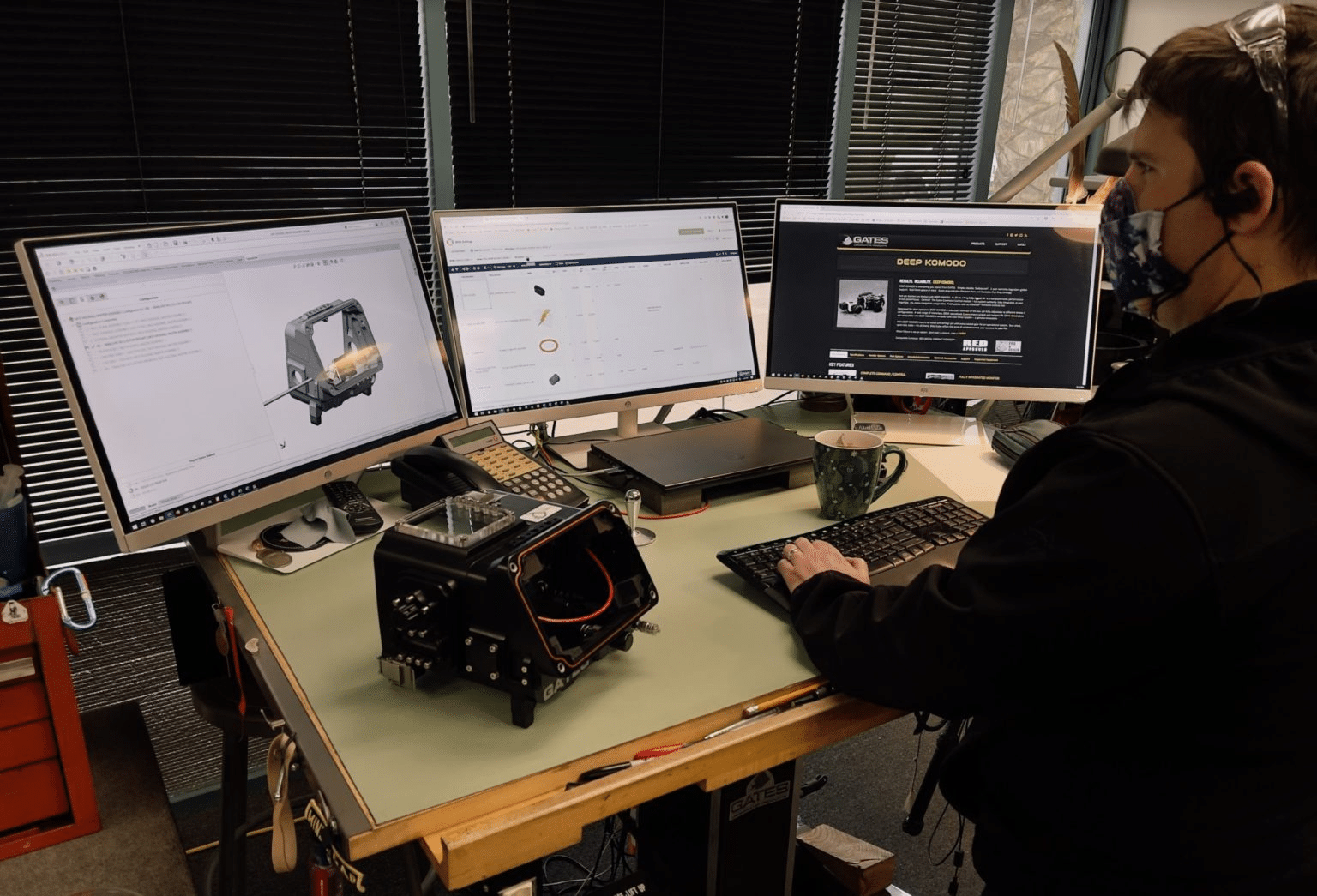

Here is another story about OpenBOM and Gates Underwater products. Read the story here.

“The OpenBOM Team product is a good fit for us as a company. We have Engineers on CAD, folks in manufacturing and assembly, and recently incorporated OpenBOM in our supply team.” John goes on to say that he appreciates how OpenBOM fits the size of his business as they scale, “I did not anticipate the overall benefit of the Solidworks integration” he says. “It was a big WOW! moment. Since then the scope of what we put in OpenBOM has grown. We can control more information, specifications, and requirements. OpenBOM forces adherence to a process! Bottom line,” says John, “OpenBOM is a perfectly suited, good value product. It’s an excellent match to our needs.”

OpenBOM Design

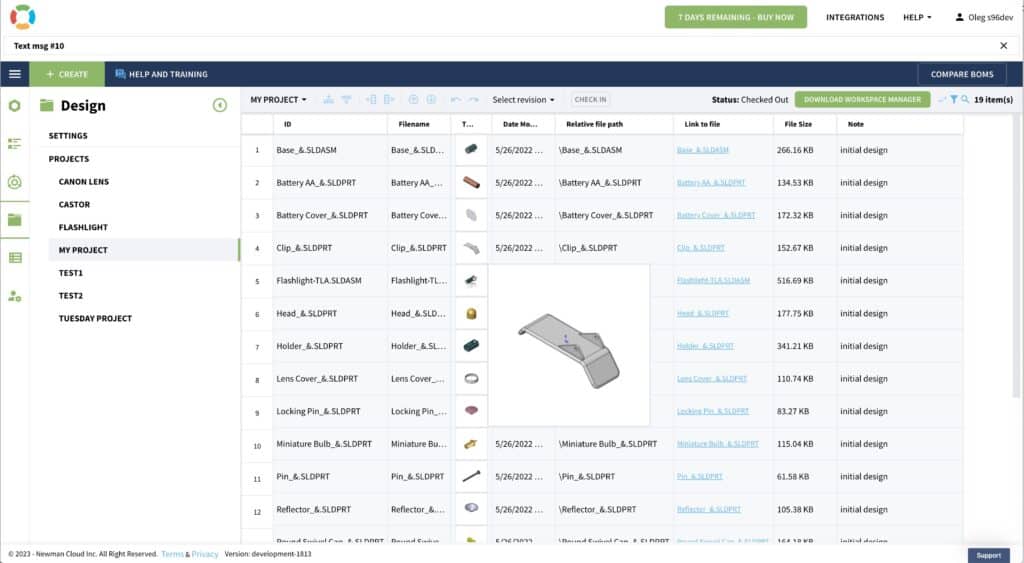

Managing files and their versions is super important. If you, like many other SOLIDWORKS users, are still storing files on your local drive or one of the cloud drives, you can find the OpenBOM Drive solution a great fit or how to get them under control immediately.

OpenBOM provides a system to manage CAD files (including Solidworks files) and other design documents. It includes OpenBOM Design Projects.

OpenBOM Design Projects allows you to manage CAD files and other documents, easily upload/download, manage revisions, and keep files in sync with your local folders. It is part of the OpenBOM Free subscription. For more information, check OpenBOM documentation.

An Integrated User Experience For SOLIDWORKS

OpenBOM cloud CAD system integrations such as Autodesk Fusion360 and PTC Onshape had browser user experience from the beginning. But now, we are coming up with a new integrated user interface for all OpenBOM add-ins for CAD systems. As part of this user experience, we provide access to Items and Bill of Materials directly from the CAD user interface, which makes it extremely easy to approach and simplify the overall user experience – everyone loves integrated UX and we know that!

Here is a heads-up on what is coming for SolidWorks. Our integration is becoming fully embedded into the Solidworks browser right panel user interface. It will include two important functions:

- Browser-based user interface showing data about BOMs, Items, and related information

- Contextual navigation allows seamlessly seeing only the BOM for a specific assembly

Conclusion

We live in a digital and connected world. The information workflow, which includes data handover, merging information coming from multiple teams, eliminating manual data entries, and reconciliation is really important. Each time you manually manage bills of materials by copying data from one place to another, updating multiple Excel spreadsheets, or manually exporting files and collecting them into zip packages you introduce mistakes that will cost your organization a lot of money, missed milestones, disrupted supply chain, and unhappy customers.

Bringing digital tools like OpenBOM to your SolidWorks environment allows you to combine both worlds – mature CAD productivity and instant cloud-based BOM data management and real-time collaboration.

REGISTER FOR FREE and start a free 14 days to check out how OpenBOM can help you today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.