Selecting a PDM or PLM system is one of the most critical decisions for an engineering team and manufacturing organization. The days when all you needed was to create drawings and build a BOM using a chalkboard are long gone.

Likewise, the era of simply choosing the PDM system provided by your CAD vendor is over. Building products today is a complex, multi-disciplinary process that goes beyond managing MCAD files and their revisions.

Products now include various disciplines—mechanical, electrical, electronics, software, and beyond (system, DevOps, cloud, etc.). Additionally, many businesses need to develop services where the physical product is just one part of the overall solution (e.g., rental models, selling software services with specialized hardware, and more).

So, what should you know to make an informed decision when selecting a PDM or PLM system in 2025?

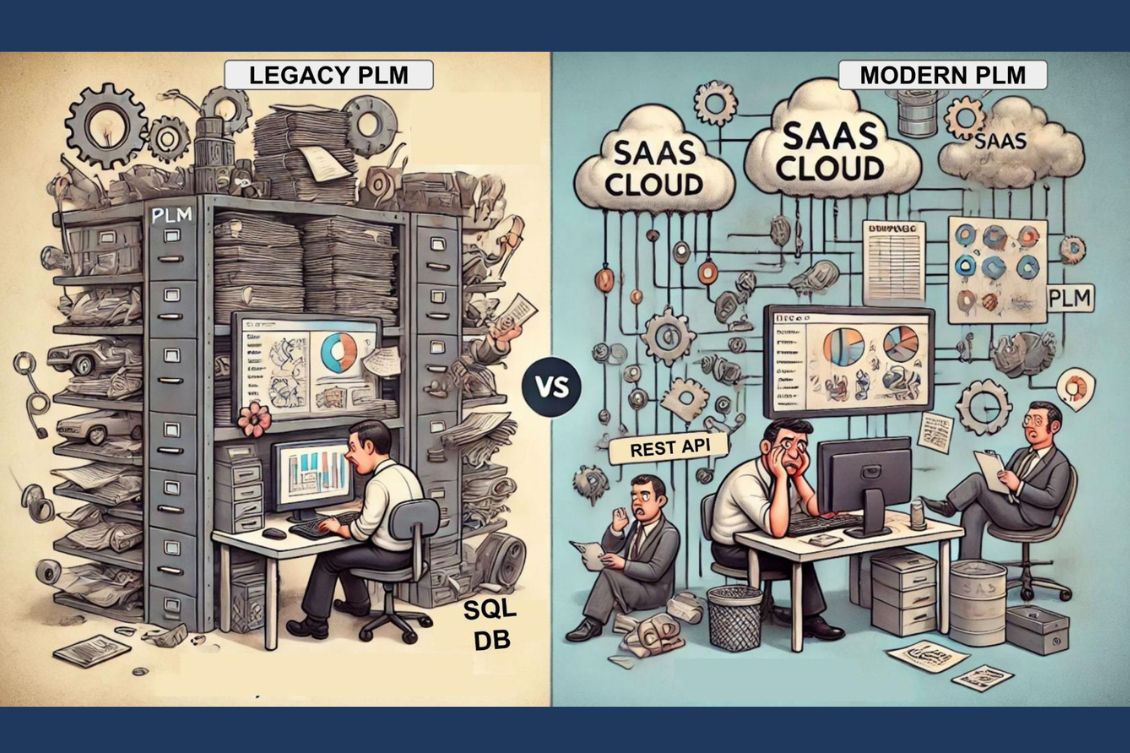

Cloud/SaaS vs. Legacy On-Prem Solutions

The dominance of on-premise PLM is nearly over. You can still buy these systems from vendors, but doing so is like buying a flip phone in the era of smartphones. If all you need is basic document management, it might be fine, but what about everything else?

Cloud-native and SaaS-based PLM/PDM solutions have become the standard. While some vendors still offer on-premise solutions, SaaS PLM provides better flexibility, scalability, and reduced IT burden. However, not all cloud solutions are the same. When evaluating vendors, consider the following:

- Is it truly multi-tenant? Multi-tenant SaaS solutions offer lower costs, continuous updates, and better security than single-tenant (hosted) PLM.

- Does it provide multi-tenant data access? Can you easily share data with external collaborators like contractors and suppliers?

- Does it integrate with cloud-native CAD and ERP systems? A modern PDM/PLM must seamlessly connect with cloud-based design and business applications.

- What are the data ownership terms? Ensure you retain full control over your data, even with a SaaS provider.

Avoid Being Locked into Traditional PDM/PLM Architectures

Legacy PDM and PLM systems were built on monolithic architectures using SQL databases. These systems often have limited capabilities, with development effectively halted 10–15 years ago. Some vendors still sell them at low prices just to keep customers locked in.

In 2025, the trend is shifting towards composable, flexible architectures that allow businesses to:

- Integrate best-of-breed applications instead of relying on a single vendor’s ecosystem.

- Utilize flexible data models, including graph databases and digital thread methodologies.

- Enable real-time collaboration across distributed teams without performance bottlenecks.

Key takeaway: Avoid vendors pushing outdated, vertically integrated PLM stacks. Instead, look for composable, API-first platforms that adapt to your business needs.

Think Beyond CAD Files—Focus on Digital Thread and Data Connectivity

The success of a PDM or PLM system is no longer just about managing files—it’s about enabling the digital thread. A disconnected PLM that only centralizes engineering data, export spreadsheets and files, but fails to integrate with manufacturing, procurement, and suppliers creates more problems than it solves.

When choosing a system, ask:

- Does it support a digital thread? The system should allow data to flow seamlessly across departments, suppliers, and partners.

- How does it manage relationships between different data entities? Flexible linking between CAD files, BOMs, change management, and supply chain data is crucial.

- Does it provide real-time visibility into product changes? Look for built-in revision control, change tracking, and automated workflows.

Search, Analytics, and AI Are No Longer Buzzwords—They’re Must-Haves

AI and machine learning capabilities in PLM have evolved from “nice-to-have” to must-have features. Companies are leveraging AI for:

- Flexible data classification and organization (e.g., recognizing part similarities and suggesting reuse).

- Enhanced search and retrieval (e.g., intelligent search for design files and part attributes).

- Analytics and real-time data connections for cost estimation, supply chain analysis, and quality management.

A modern PDM/PLM should not just store data—it should provide actionable insights. Be wary of vendors making vague AI promises—look for real, working solutions.

The Future is Open—Check for Trials and Avoid Vendor Lock-In

It’s 2025, and if you cannot freely try a solution before committing, something is wrong. More than likely, you’re looking at a 20-year-old system (maybe hosted in the cloud, requiring virtual machines) and a lengthy sales process instead of a true SaaS product.

Openness is key. Check how you can get your data out of the system and steer clear of proprietary solutions that make integrations and migrations difficult.

To future-proof your investment, choose a system that:

- Uses open APIs and supports industry standards (e.g., REST, GraphQL).

- Allows for easy data export and migration.

- Does not force you into a closed ecosystem.

Conclusion

Think data first. Data is the foundation of every engineering and manufacturing organization, and it lives much longer than the software that manages it. Therefore, the key elements of any modern PDM/PLM software are flexibility, openness, and transparency.

Interested in learning more about OpenBOM? REGISTER FOR FREE and see how OpenBOM can help you.

Best,

Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.