In 2024, contract manufacturing is in the midst of a transformation. This transformation comes as a result of the evolving demands of their customers. As manufacturers are looking to adopt new technologies and improve their supply chain strategies, it leaves contract manufacturers (CM) embracing certain changes.

CMs are evolving beyond their traditional role. It’s now a dynamic partnership, shaped by technological progress and the need for innovative solutions. This shift isn’t just a trend; it’s a fundamental change that’s redefining the industry.

In this blog, we will go over the five key trends reshaping CMs in 2024. From advanced automation to sustainable practices and the digital transformation of processes, each trend is a part of the goal to offer a better solution to their customers.

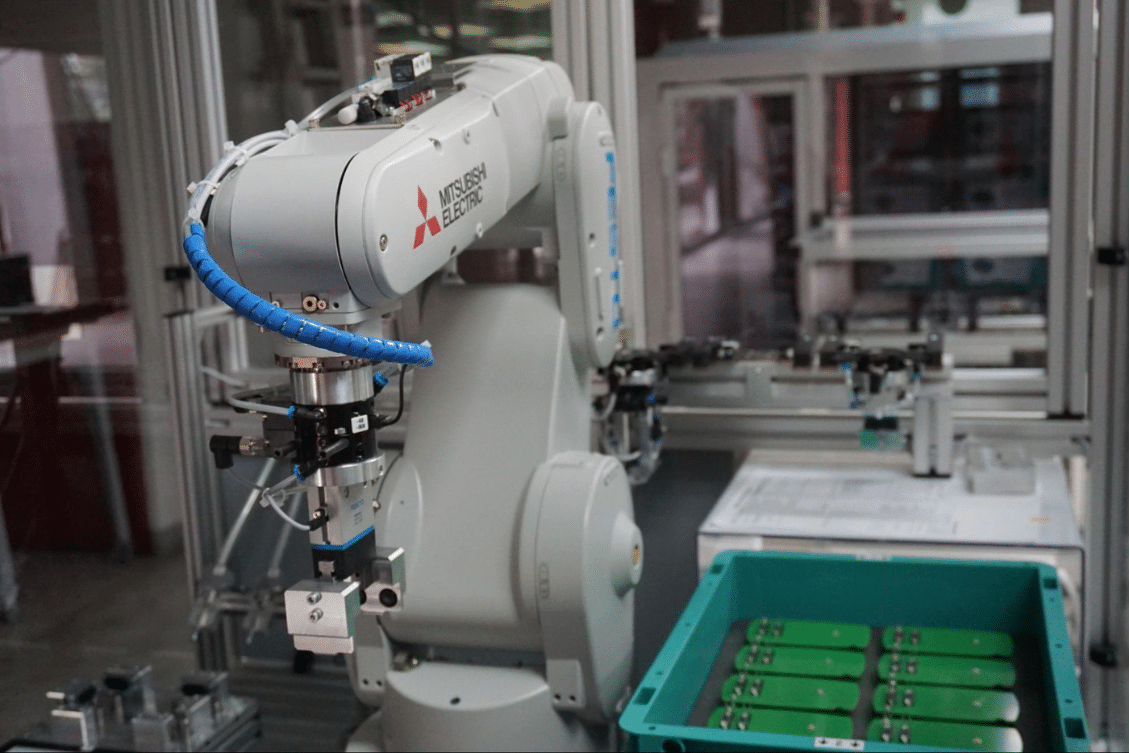

Trend 1: Advanced Automation Integration

The integration of advanced automation stands out as a defining trend in 2024. This shift goes beyond the conventional role of automation in streamlining processes; it’s a leap into a future where artificial intelligence (AI) and robotics redefine the production line.

Automation has long been important in manufacturing, and in 2024 we see it going beyond routine tasks. Advanced automation will continue with the integration of smart technologies that can adapt, learn, and optimize processes autonomously.

Integration of AI and Robotics for Enhanced Efficiency

At the front end of this trend is the bonding between AI and robotics. AI-driven systems enhance decision-making, allowing machines to adapt to dynamic production requirements. Robots, equipped with advanced sensors and machine learning capabilities, collaborate seamlessly with human workers, improving precision and speed on the factory floor.

The benefits of this trend extend beyond the shop floor. For CMs, it means increased productivity, reduced costs, and improved quality control. For their customers, they can expect faster turnaround times, greater customization capabilities, and a more responsive supply chain.

Trend 2: Sustainable and Eco-Friendly Practices

The trend toward sustainable and eco-friendly practices is no longer an ethical choice, it’s a fundamental transformation shaping the future of manufacturing.

Sustainability is no longer a fringe consideration but a central focus for CMs. The industry is recognizing the importance of reducing its environmental footprint and addressing concerns about resource depletion, pollution, and climate change. This emphasis is not only a response to societal expectations but also a strategic move to future-proof operations.

Adoption of Eco-Friendly Materials and Processes

At the core of this trend is a commitment to adopting eco-friendly materials and processes. From the sourcing of raw materials to the disposal of end products, manufacturers are reevaluating their entire production lifecycle. Renewable resources, recycled materials, and energy-efficient practices are becoming key components of the manufacturing equation.

CMs embracing this shift are not only contributing to a healthier planet but are also aligning themselves with a market that increasingly values ethical and sustainable choices. As we explore this trend, it becomes evident that the future of manufacturing is not just efficient and innovative but also environmentally conscious.

Trend 3: Digitalization and Industry 4.0

As we navigate manufacturing in 2024, the impact of digitalization and Industry 4.0 technologies is unmistakable. This transformative trend is reshaping manufacturing processes, creating a more connected, intelligent, and responsive ecosystem.

Industry 4.0 represents the fourth industrial revolution, combining digital technologies, data analytics, and smart manufacturing. In manufacturing, this translates to the integration of IoT (Internet of Things), AI, and cyber-physical systems into the production lines.

At the heart of this trend is the IoT, where interconnected devices communicate and share data in real-time. This connectivity extends from the factory floor to the supply chain, enabling manufacturers to gather and analyze vast amounts of data. Collecting data through AI provides insights that can optimize production efficiency, predict maintenance needs, and enhance overall decision-making.

Digitalization is not just about embracing new technologies; it’s a transformation of operational processes. From smart sensors monitoring equipment performance to predictive maintenance algorithms minimizing downtime, the digital thread woven through production lines enhances efficiency, reduces costs, and ensures a level of agility crucial for thriving in today’s fast-paced markets.

Trend 4: Flexibility and Customization

In 2024, the manufacturing landscape is witnessing a paradigm shift as the industry places a premium on flexibility and customization. CMs are no longer confined to rigid production processes, instead, they are embracing agility to meet the diverse and evolving needs of their clients.

One of the defining aspects of this trend is the growing demand for customized manufacturing solutions. Clients are seeking more than standardized production runs, they desire products tailored to their specific requirements. This shift reflects an acknowledgment that one size does not fit all, and the ability to offer personalized solutions is a competitive advantage.

Flexibility is no longer an option but a necessity. CMs are reconfiguring their production lines to be adaptable to changing demands. This might involve quick changeovers between product variants, scalable production capacities, or even the ability to accommodate last-minute design modifications. The goal is to be responsive and agile in a market where change is constant.

Trend 5: Supply Chain Resilience

The last trend of 2024 for CMs is the importance of supply chain resilience. The ability to anticipate, adapt, and recover from disruptions has become increasingly important in the global supply chain.

Supply chain resilience is no longer a buzzword but a fundamental requirement for CMs. The industry recognizes that disruptions, whether caused by geopolitical events, natural disasters, or unforeseen challenges, can have cascading effects on production. A resilient supply chain can absorb shocks and continue to deliver consistent results.

Strategies to Enhance Supply Chain Resilience

Manufacturers are diversifying their supplier base, embracing digital technologies for real-time visibility, and strategically stockpiling critical components. The aim is not only to weather disruptions but to position the supply chain as a strategic asset that adds value to the overall manufacturing process.

In a globalized world, challenges in one part of the supply chain can echo across continents. CMs are proactively identifying potential risks and developing mitigation strategies. This might involve creating contingency plans, fostering closer collaboration with key suppliers, or investing in technology that provides early warnings of potential disruptions.

Conclusion

CMs in 2024 need to emerge by dynamic shifts and pioneering trends. As we explored the five key trends shaping the industry, it became evident that the future of contract manufacturing is not just about production but about redefining how businesses approach innovation, sustainability, and adaptability.

The relationship between manufacturers and CMs is no longer just transactional; it’s a strategic collaboration that requires a proactive approach to stay ahead. The trends highlighted in this exploration are not isolated occurrences but interconnected threads weaving a narrative of innovation and adaptation.

Regards,

Jared Haw

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.