Imagine that, you found OpenBOM, registered for free, experimented with your favorite project, collaborated with your team, and found that OpenBOM is what you need. You approached your boss and asked to approve the purchase, but were asked for a “bigger picture of ROI”. It is understandable. Buying OpenBOM is different from buying an iPhone app.

In the world of business, making a strong case for software purchases to your boss is no laughing matter. The decision to invest in new PLM software carries significant implications for your team’s productivity, operational efficiency, and overall success. It’s crucial to approach this challenge with a serious mindset, understanding the importance of aligning the software purchase with your company’s objectives and financial considerations. Companies are looking at how to use new PLM technologies in the era of the digital industrial revolution to fundamentally change the manufacturing industry. However, it is unusual to see companies that manage manufacturing processes using Excel and spreadsheets instead of using PLM systems. It was not a surprise, because old legacy PLM systems are only good for large-scale production companies with very complex manufacturing processes. But I have good news – OpenBOM is built from the ground up to use the latest achievements in data management and cloud technologies to deliver new PLM experiences. It can streamline the manufacturing process, optimize the usage of raw materials and streamline your product lifecycle management and supply chain management. It takes PLM beyond the traditional mechanical engineering field to manage your product as a system combined with mechanical, electronic, and software components.

In this blog post, we will step into the art of justifying software purchases to your boss, focusing on practical strategies and persuasive arguments to present a compelling case. While the topic may not elicit belly laughs, the satisfaction of successfully securing the support you need will undoubtedly bring a smile to your face.

Let’s breakup with old habits or why Excel is not enough

The truth is that your boss doesn’t like Excel. But breaking with old habits can be hard and stepping into a new space of data management outside of his comfort zone requires some preparation. Every manufacturing company we worked with has its “Excel sins”. It is called – an items spreadsheet, my product spreadsheet, purchase spreadsheet, and cost spreadsheet. Familiar with that? Read more about how to get rid of them –3 Steps Beyond Excel Strategy.

In today’s fast-paced and interconnected business environment, it’s vital for businesses to streamline and enhance their operations, especially when it comes to managing product data and processes. This is where OpenBOM (Open Bill of Materials) comes in. A cloud-based software that centralizes product data, OpenBOM brings tons of benefits that can significantly improve efficiency, cut costs, and reduce errors. Here are five key values of OpenBOM that you should emphasize when pitching it to your boss.

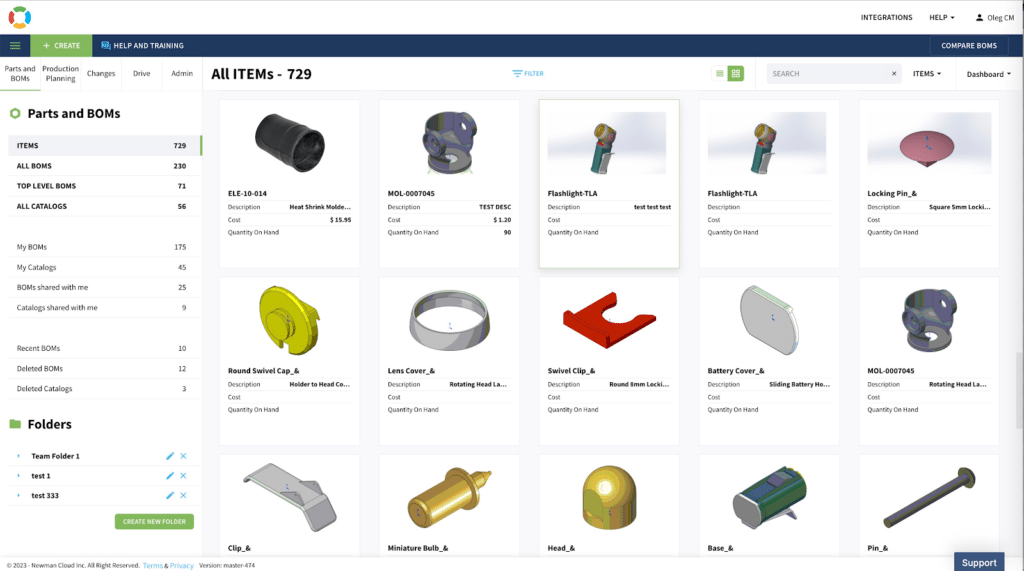

1. A Single Source of Truth About All Product Information

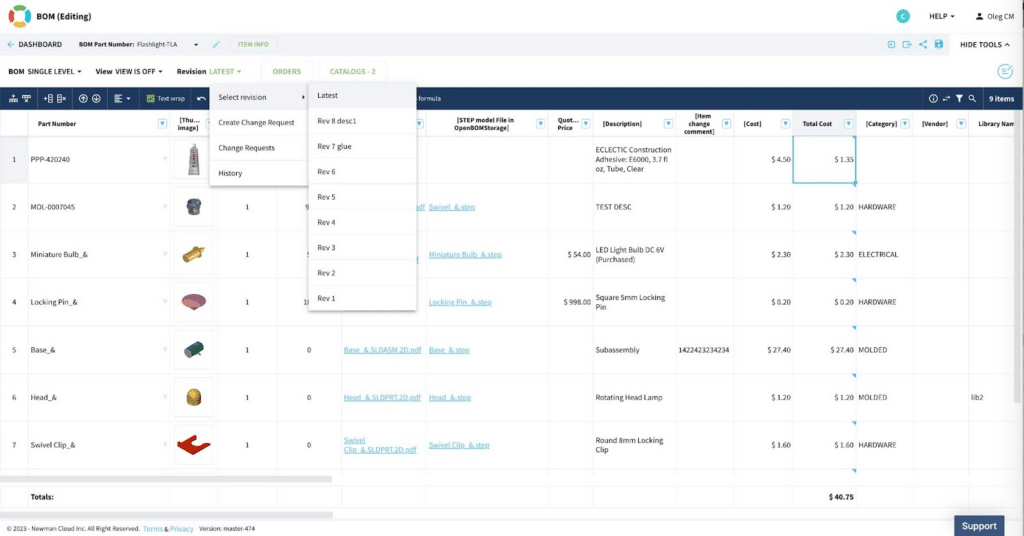

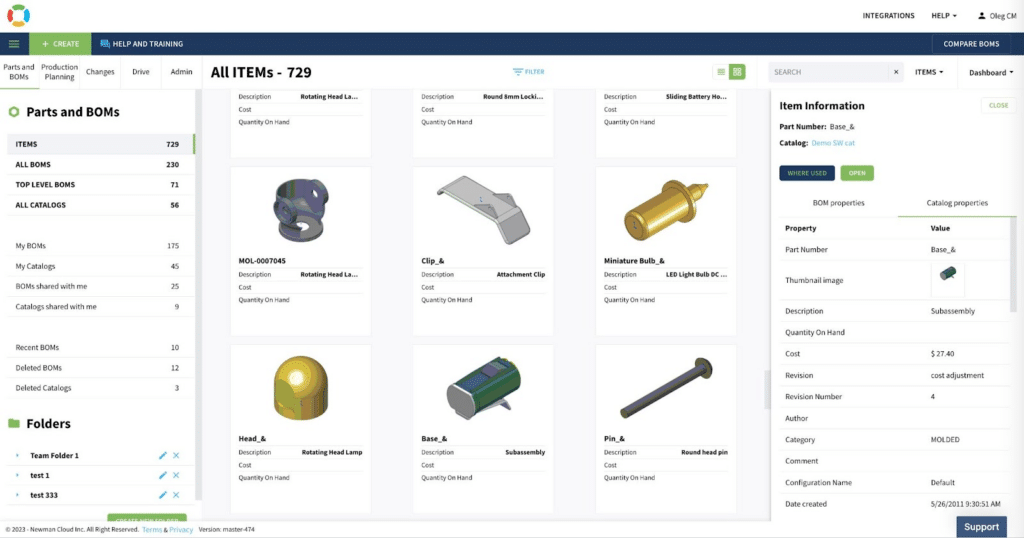

One of the biggest challenges in managing product data is ensuring consistency and accuracy across all teams, software, and departments. OpenBOM solves this by serving as a single source of truth for all product information. By centralizing all data in one flexible and scalable data model, OpenBOM eliminates data silos (MCAD BOM, ECAD BOM, Software BOM, etc), improves access to information, and ensures everyone is working with the same, most up-to-date data. This can greatly increase efficiency, reduce confusion and miscommunication, and improve decision-making. All data, revisions, files, and related information is available to everyone from a user-friendly and simple OpenBOM environment.

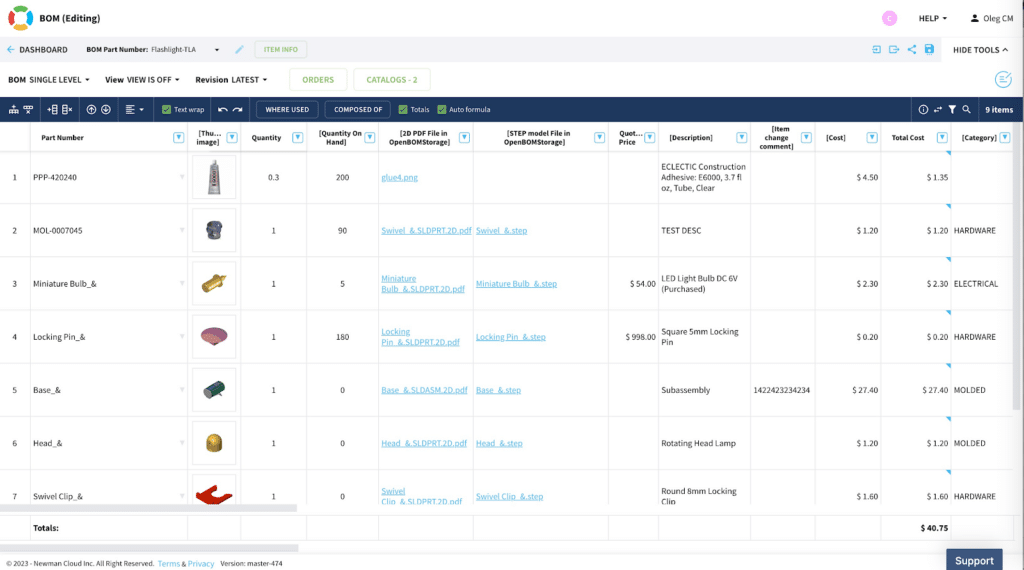

2. Better Analysis and Cost Management

OpenBOM’s comprehensive and integrated view of product data allows for powerful analysis and cost management. Starts from where simple “where used” query that allows you in a simple way to analyze the impact of changes and find all relevant assemblies and projects. Cost is another one. Everyone wants to be able to calculate product cost at any stage of product development and OpenBOM gives you this option using flexible formulas. It helps your team to make proactive decisions based on the real cost data. This kind of cost transparency can be a game-changer in terms of profitability and competitiveness.

3. Fewer Mistakes in Data Creation and Management

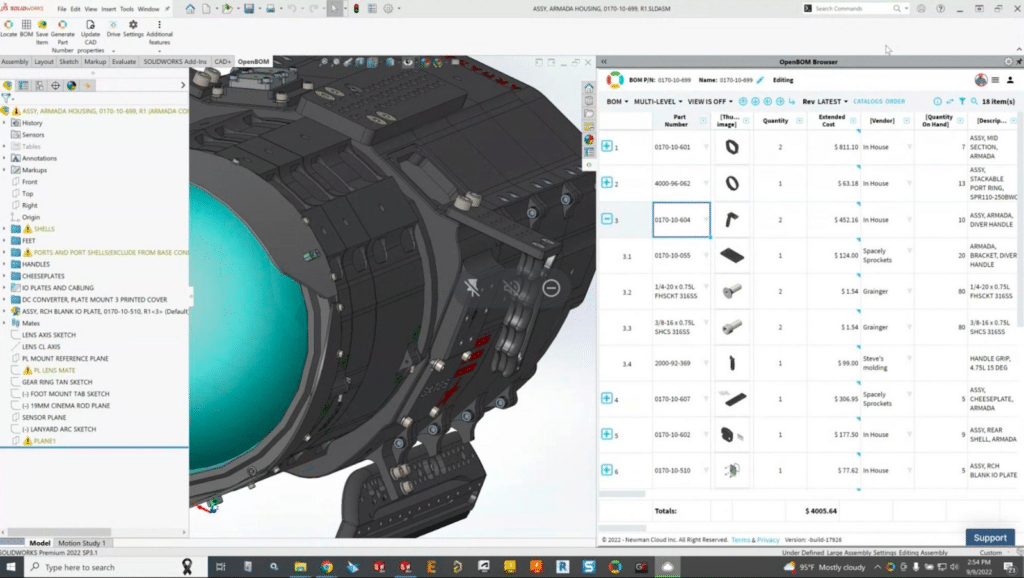

With OpenBOM, the risk of errors in data creation and management is significantly reduced. The software automates many data management tasks, which not only saves time but also minimizes the possibility of human error. Here are a few examples of how OpenBOM eliminates manual tasks that can introduce errors:

- automatically capture data from engineering environments (e.g. CAD)

- automatically generate derivative files (STEP, PDF, DXF, etc)

- automatically export or share data with contractors or suppliers (RFQs/PO)

Additionally, it maintains a historical record of all data, which makes it easy to track everything. Now, no one can tell you that you send the wrong file to the supplier or shared incorrect data with your customer. OpenBOM remembers everything. OpenBOM can save your company both time and money and help maintain your reputation for quality and reliability.

4. Coordinated Changes and Traceability of Who Did What and When

OpenBOM’s robust change management features allow for coordinated changes across all departments. Any changes made to the product data are instantly updated and reflected across all users, ensuring everyone is working from the same page.

The foundation of this process is change request and change management functions allowing control of the process of changes and new revision introductions.

Moreover, OpenBOM provides a detailed log of who made what changes and when facilitating accountability and traceability. This makes it easy to audit processes, investigate issues, and ensure compliance with regulations and standards.

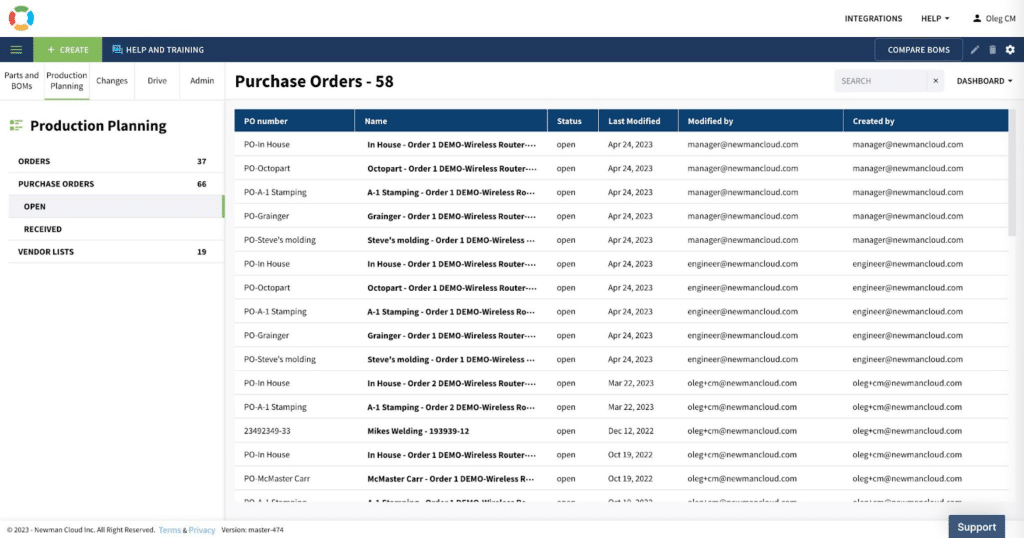

5. Improved Quality of Purchasing Process

Lastly, OpenBOM can greatly enhance the quality of your purchasing process. By providing a mechanism to manage inventory, vendors, and purchasing price history, it allows you to keep everything in check, to be sure the right quantities will be ordered and multiple suppliers are checked.

By providing a clear view of all product information, it makes it easier to plan and execute purchases efficiently. It allows for better vendor evaluation, as you can easily compare costs and other important factors. It also improves communication with suppliers by providing a single, accurate source of product data. By improving your purchasing process, OpenBOM can help you get better value from your suppliers and ensure a steady supply of the materials you need.

Conclusion:

Automation, fewer errors, more transparency, and traceability. These are the main outcomes of OpenBOM implementation. OpenBOM provides immense value in the form of enhanced data accuracy, improved cost management, reduced errors, better change coordination, and improved purchasing processes. By incorporating OpenBOM into your operations, you can boost efficiency, reduce costs, and enhance the overall effectiveness of your product data management.

If you didn’t do it yet, REGISTER FOR FREE and try OpenBOM today with our 14-day free trial.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.