Manufacturing businesses are experiencing an increased amount of challenges in this modern business environment, which is characterized by increased cost pressure, supply chain shortages, distributed markets, and complexity of resources availability.

New Manufacturing Environment

The shift to remote work has created silos in already distributed teams and makes it more difficult than ever to coordinate their work. Modern products are more complex than ever and bring another level of difficulty to already complex data management challenges.

In such an environment, it is essential for a company to rely on a solid data management foundation to create a single source of data about the products and allow the teams to coordinate their work and work more efficiently.

The Problem with Excel

For many manufacturing companies, relying on spreadsheets is a first choice in attempting to solve manufacturing data management challenges, but it is far from what is needed. Companies that continue to invest in their “fancy” spreadsheet solutions are digging themselves into a spreadsheet hole. The more they do so, the more effort will be needed to get out of this Excel spreadsheet.

Typical spreadsheet related issues are:

- Data redundancy

- Duplication of records

- Incorrect information (because of data redundancy and dupes)

- No mechanism to manage revisions and changes

- No good mechanism to share the data and stay on the same page

6 OpenBOM Essentials

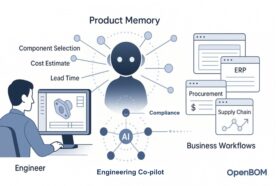

OpenBOM is here to help you replace Excels and to advance your business. Here are 6 essential OpenBOM solutions that will make your decision about OpenBOM easy.

1- Single Source Of Data

To have a single storage place for all your data is a key starting point. OpenBOM provides super robust information storage for structured data, flexible data model, semantic relationships, multiple types of structured properties, and many other capabilities that makes your product data easy to manage. It is visual, connected, and globally available, which is another big reason why your distributed data and teams will be very pleased to use OpenBOM.

2- Streamline Information Flow via Integrations

Each time you copy a piece of data from one application to another, you create a potential mistake. Things can go wrong, the data can be mistyped, copied in a different place, lost… Therefore, the strategy should be to create a seamless information flow that will help you stay out of trouble and manage data flowing between multiple applications. In many cases, it will be the same data, but presented differently in multiple accounts. In some other situations, it will be the mechanism to extract the data (eg. 3D CAD system) and place it in the OpenBOM application automatically by merging all changes.

3- Formulas and calculations

Just having the data is not enough. Engineers need to perform multiple calculations and OpenBOM gives flexibility to data management combined with the formulas to perform multiple calculations such as rollups, calculations of unit cost, and many others. Rollups (especially multi-level rollups) are extremely useful and powerful because they can do with product structure something that no Excel can do.

4- Revisions and Changes

Change is the only constant thing and it applies very well to product development and manufacturing. Managing changes is extremely important. OpenBOM gives you an out-of-the-box mechanism to capture changes automatically as well as create revisions and manage change requests. This mechanism scales from a very simple automatic process in which everything you do when editing the data is captured to a more complex and sophisticated mechanism allowing the team to control changes, capture baselines, and revisions.

5- Planning Tools

Getting things done is the goal of every manufacturing process. You don’t make a bill of materials for the sake of BOM only – it is a tool to plan your production process and to get the list of components and tasks to purchase components and make/assemble things. OpenBOM gives you tools that allow you to manage vendors, connect vendors to planning orders, and later to the purchasing process and release RFQs and POs.

6- Instant Data Sharing and Collaboration

A big value in OpenBOM is to provide a way to share data instantly with anyone who needs it and that is allowed access to it. It includes other people in your organization as well as contractors and suppliers. The sharing mechanism in OpenBOM is easy and seamless. You can manually share the data or you can automate the process by defining people’s roles and managing special team user-defined views to control what information is shared and how it can be accessed.

For more information about OpenBOM tools and capabilities, check out our Product Tour page on the website.

Conclusion

OpenBOM is a simple yet powerful and robust service that is available globally. You can start using it at any time and get advantages of data management, data sharing, revision, and lifecycle control as well as more advanced features such as production and procurement planning. It is a new digital environment that provides a modern way for companies to leave Excel and other spreadsheets behind and focus on how to manage data and collaborate in a new way.

REGISTER NOW to check out what OpenBOM can do for you and start your 14-day free trial today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.