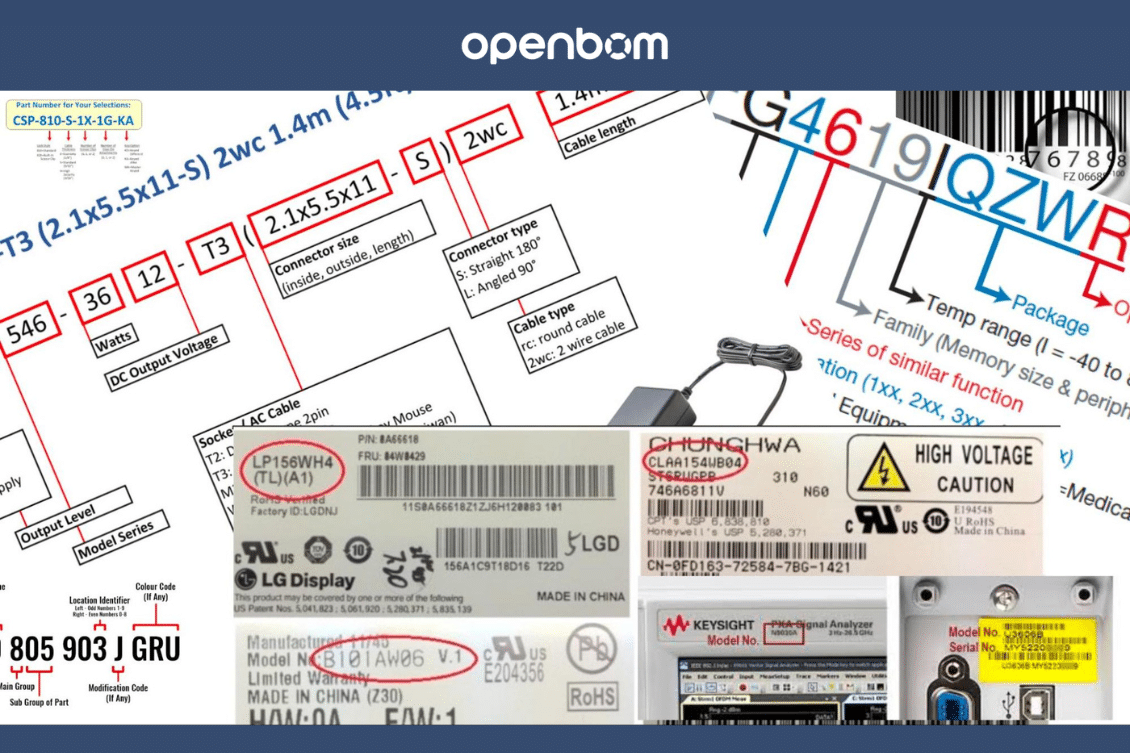

In the complex world of engineering and manufacturing, part numbers form a hidden language that orchestrates the processes of manufacturing. I usually call the Bill of Materials (or Bill of Information) a lifeblood of manufacturing. I can think about Part Numbers as an important element of this manufacturing vessel system. They provide an identification system for everything in manufacturing and engineering, helping us to manage data inside each engineering and manufacturing company, and also to perform communication with organizations outside – contractors and suppliers. Without good identification and reference system, the industry will not be able to live, products won’t be manufactured, components will not be shipped and compliance standards won’t be followed. Part Numbers seemingly simple identifiers are gatekeepers of information and efficiency. They help streamline processes, enhance productivity, and foster innovation in a realm where precision is king.

Part number topic is too big to cover in a single blog. Earlier this week, we published a series of articles reflecting on understanding, complexity, best practices, and misconceptions related to part numbers.

This blog post gives you a quick summary and also important links to dig deeper into the topic and learn about best practices for managing part numbers in engineering and manufacturing systems.

Unraveling the Complexity of Part Number Management

Part numbers are fundamental to data management in manufacturing and engineering organizations. However, they can be a source of confusion and debate. Their management complexity arises from the intersections with identification systems, legacy data, and external references. Acknowledging and addressing these complexities can enhance data exchange, streamline processes, and promote accurate data management.

Learn more about it here.

Part Numbers vs. Rich Attributes in PDM/PLM

In today’s hybrid, data-driven landscape, striking the right balance between meaningful part numbers and rich attribute sets is crucial. Part numbers have been traditionally used to identify components, their configurations, and sometimes documents across various data management systems, such as CAD, PDM, PLM, and ERP systems. Leveraging intelligent systems, it is possible to derive part numbers from relevant attributes and enhance them with rich attribute sets. This hybrid approach ensures efficient collaboration, seamless data integration, and effective decision-making.

Learn more about it here.

File Name vs. Part Number: Clearing Confusion

A common question that arises in engineering and manufacturing companies is whether file names and part numbers are the same. To clarify, they represent separate entities with different lifecycles and purposes. Establishing clear identification, connection, and distinction between CAD files and items/BOMs can lead to a more coordinated and connected process, resulting in better product lifecycle management (PLM).

Learn more about it here.

The Significance of Part Numbers in Contract Manufacturing

In contract manufacturing, part numbers play a pivotal role in ensuring accurate identification, effective communication, efficient inventory management, and rigorous quality control. The decision of whether to use supplier part numbers or not often leads to debates. Regardless of the choice, managing these part numbers correctly is essential to avoid potential issues.

Learn more about it here.

Optimizing Part Number Management with OpenBOM

With the aid of OpenBOM’s tools and best practices, companies can navigate the complexities of part number management efficiently. By correctly identifying every part or assembly, configuring part numbers in OpenBOM catalogs, and providing flexibility in part number generation and management, OpenBOM aids companies in achieving their data management goals.

Learn more about it here.

Conclusion:

Part number management is a vital yet often misunderstood aspect of data management in engineering, manufacturing, and operations. Wrong decisions about part numbers can lead to significant overhead in the management of data and processes, lead to mistakes, and complex data management synchronizations. Part Numbers are one of the longest-staying legacies in every manufacturing business. Once introduced, it is very hard to change it. But with the right understanding and smart use of modern data management tools, companies can optimize their operational efficiency and success.

Confused about your Part Numbering strategy? Looking to learn more? Want to discuss your Part Numbering strategy?

Contact us to schedule a meeting.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.