There has always been pressure on manufacturing companies to decrease the price of their product. However, during these difficult times, it seems like each time you receive a quote from your supplier, it is higher than it was before.

With these price increases, how can you sustain and grow your business? The Chron says “the best way to increase your profit margin in manufacturing is usually to lower the product’s manufacturing costs rather than increasing the price of the product.”

So, how do you decrease the price of your product during material inflation and multiple supply chain problems?

The common workaround is to buy more inventory. But, inventory has its own costs. It also takes away from the budget to drive sales. So potentially, you are put in a situation where you have inventory but had to decrease the amount of money to promote your product.

The best way to proceed is to take a step back and see how you can decrease the cost of your product. These are the steps to decrease your product’s price.

What is your target price?

During part inflation, supply chain crunch, and a chip shortage, you might find it difficult to know where to start and to even know what number is feasible.

Regardless, you need a goal of what your cost of goods sold (COGS) or landing cost is. If you are outsourcing production, calculating your landing costs will be important. The recent supply chain trends will impact your shipping fees.

What are your COGS?

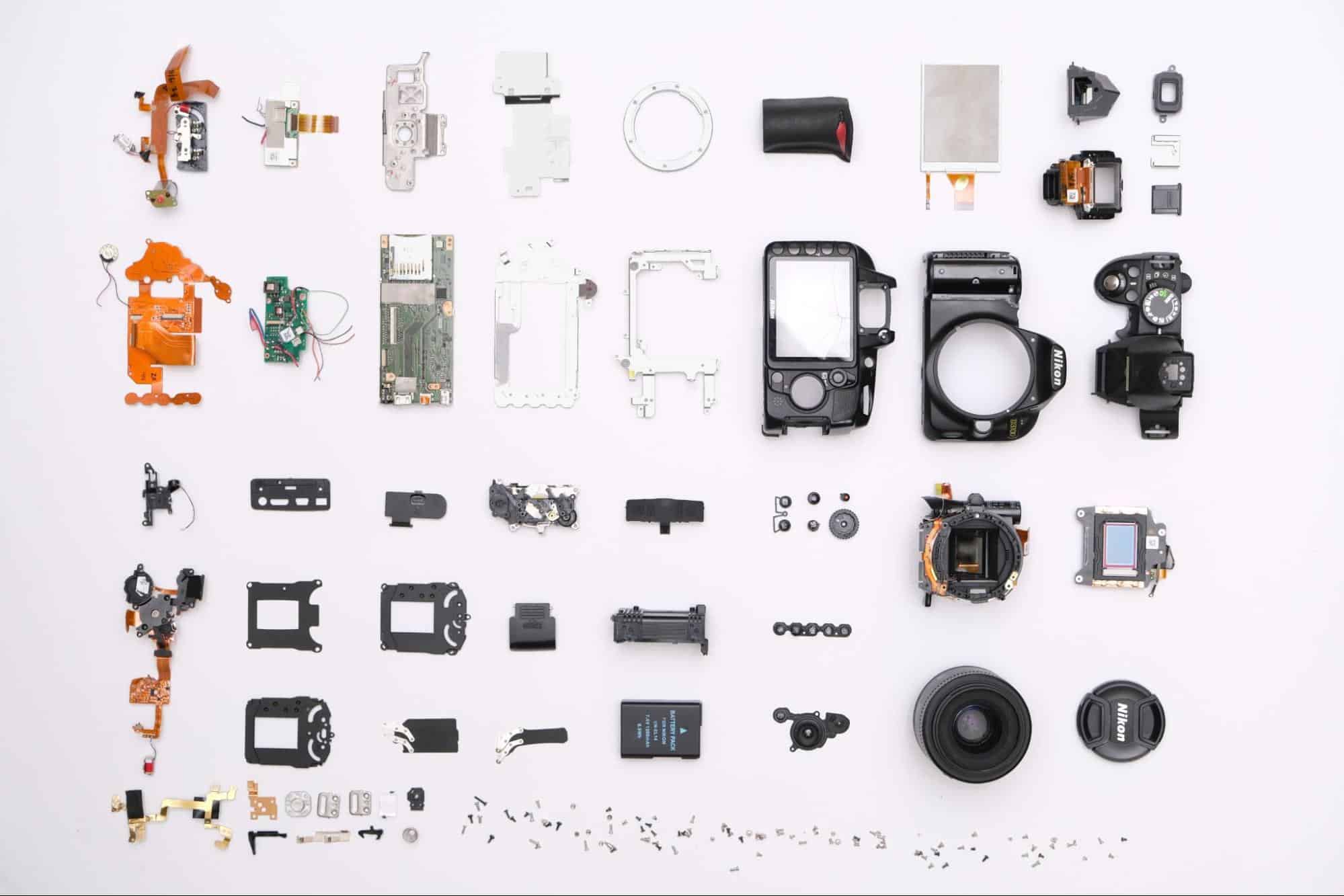

It is important to have a breakdown of the costs associated with each part and item in your product. For example, if your product consists of 25 unique parts, then you will need 25 quotes. One quote is associated with each item.

Once you have visibility into your costs, you will be able to identify the low-hanging fruit and start your project from there.

What can you optimize?

Here are a few parts you can look at changing or optimizing.

Material:

For each type of material, there are different grades. For example, aluminum has many different series and grades. Understanding the different grades and the applications recommended for each grade will help you know if you can change the grade of material you are using.

If the product is specified for aluminum 7075 to be CNC’d then it will cost more than aluminum 6061. The question is whether or not you need a better grade? If not, you are paying more for raw materials.

Process:

The manufacturing process you use also dictates the price of the product. There are so many different types of examples. For a new product introduction (NPI), you might be keen to lower your tooling investment and pay a bit more for mass production. However, as you scale, you might want to change the fabrication.

Two fundamental examples of potential changes in processes are the following:

- Changing from CNC to Die Casting.

- Deciding to powder coat or anodize your parts.

Design:

The cost of the product is heavily influenced by the design. In fact, It is thought that approximately 70% of the manufacturing costs of a product derive from design decisions made in the early design stages, such as materials used or method of manufacturing. If your product is designed poorly then you can expect multiple quality problems. A product with quality problems leads to increased costs.

Also, each time a product is touched, it adds cost. It doesn’t matter if it’s during fabrication, transportation, storing, assembly, or final quality control. Additional touches add costs. A product that can combine parts, and reduce the number of manual touches will yield a more cost-effective product.

Finishes:

Finishes affect the aesthetics of your product so you must align this with marketing. Nonetheless, the type of finish you use on a product does affect the price of the product.

Some of the most common finishes include:

- Powder Coat

- Anodize

- Sandblast

- Brush Metal Finish

Understanding the costs of each and how they will affect your product will be important.

What Can You Do Today?

Creating requests and changes to your parts must be managed. It is easy to lose historical data or fail to share it with the correct team members or fail to follow the correct approval processes.

OpenBOM is a cloud-based platform to manage your engineering and manufacturing data. Companies from startups to Fortune 500’s use OpenBOM to create a centralized database to bring in, store and manage their manufacturing data. With this infrastructure, users also use OpenBOM to streamline both their change management and PO processes.

If you need to improve the way you manage your data and processes, contact us today for a free consultation.

Regards,

Jared Haw

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.