I was attending the Digital Factory 2023 event yesterday in Boston. Organized by Autodesk and Formlabs, it was a great opportunity to meet many manufacturers and software developers together and discuss the opportunities and challenges of engineering and product development.

One of the topics that clearly stands up these days and is mentioned by almost everyone is related to how to accelerate product development speed. Everyone is looking at how to build products faster, but the reality of complex products, teams, and communications stands in front of that.

This message came clear in the keynote presentation by Autodesk CEO Andrew Anagnost that spoke about how software can help to break silos and connect teams with the data. One of the important aspects was related to breaking proprietary software file formats is super painful in the industry.

Autodesk’s strategy to make data seamlessly available via data APIs focuses exactly on the problem. You can learn more about what Autodesk does in this direction from my articles last week reviewing what I learned at Autodesk DevCon 2023 in San Francisco.

OpenBOM Support Autodesk Platform Services

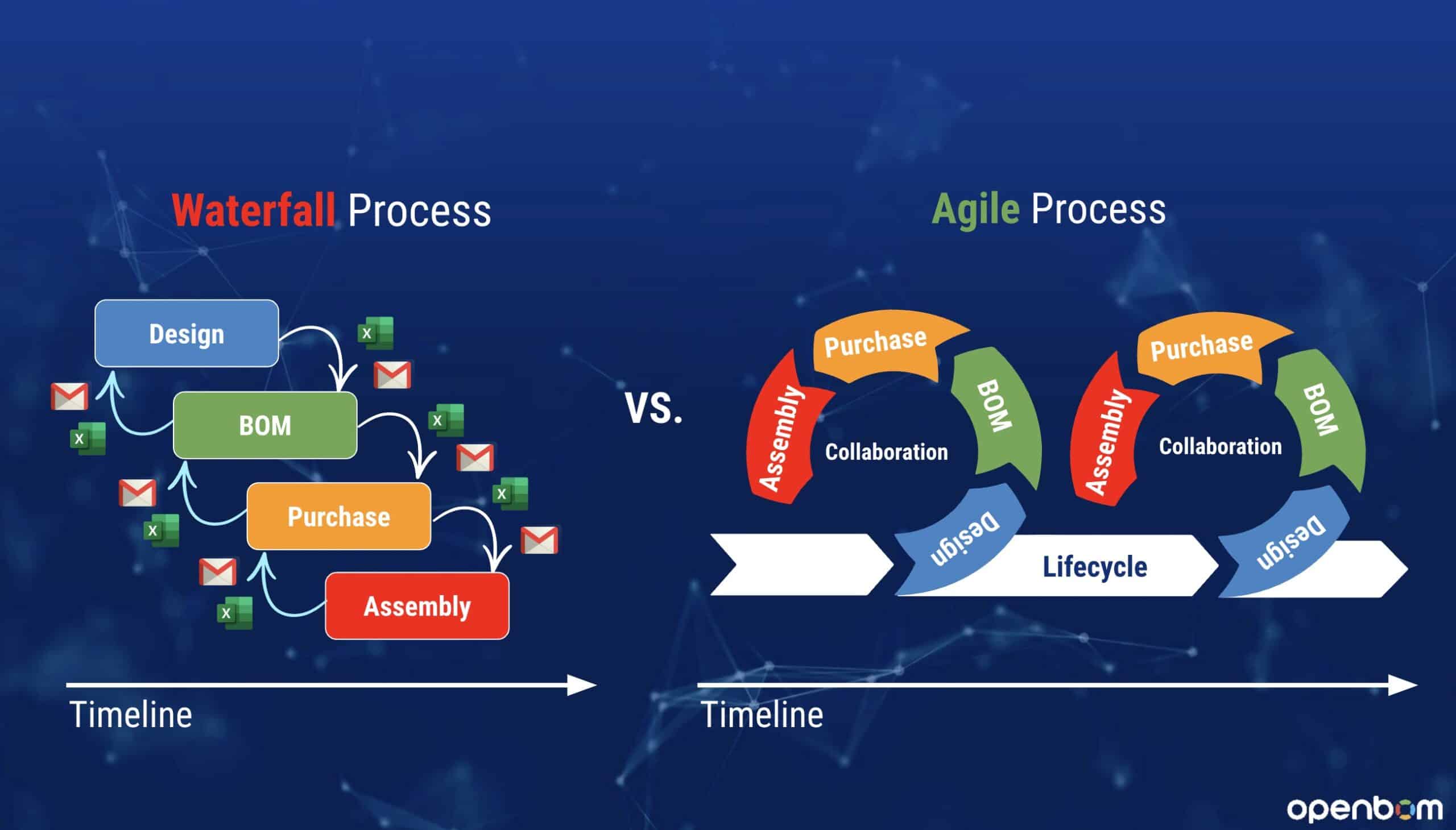

Autodesk and OpenBOM are seamlessly integrated using new data APIs provided by APS (Autodesk Platform Services) enabling the streamline of data between applications and by doing so to connect teams of engineers, production planners, and procurement organizations to work seamlessly together. Instead of exporting data to Excel, OpenBOM collaborates with engineering information sources (eg. Autodesk APS data API) and also connects teams using patented OpenBOM collaboration methods. Altogether it supports agile product development methods instead of using old-fashioned Excel exports.

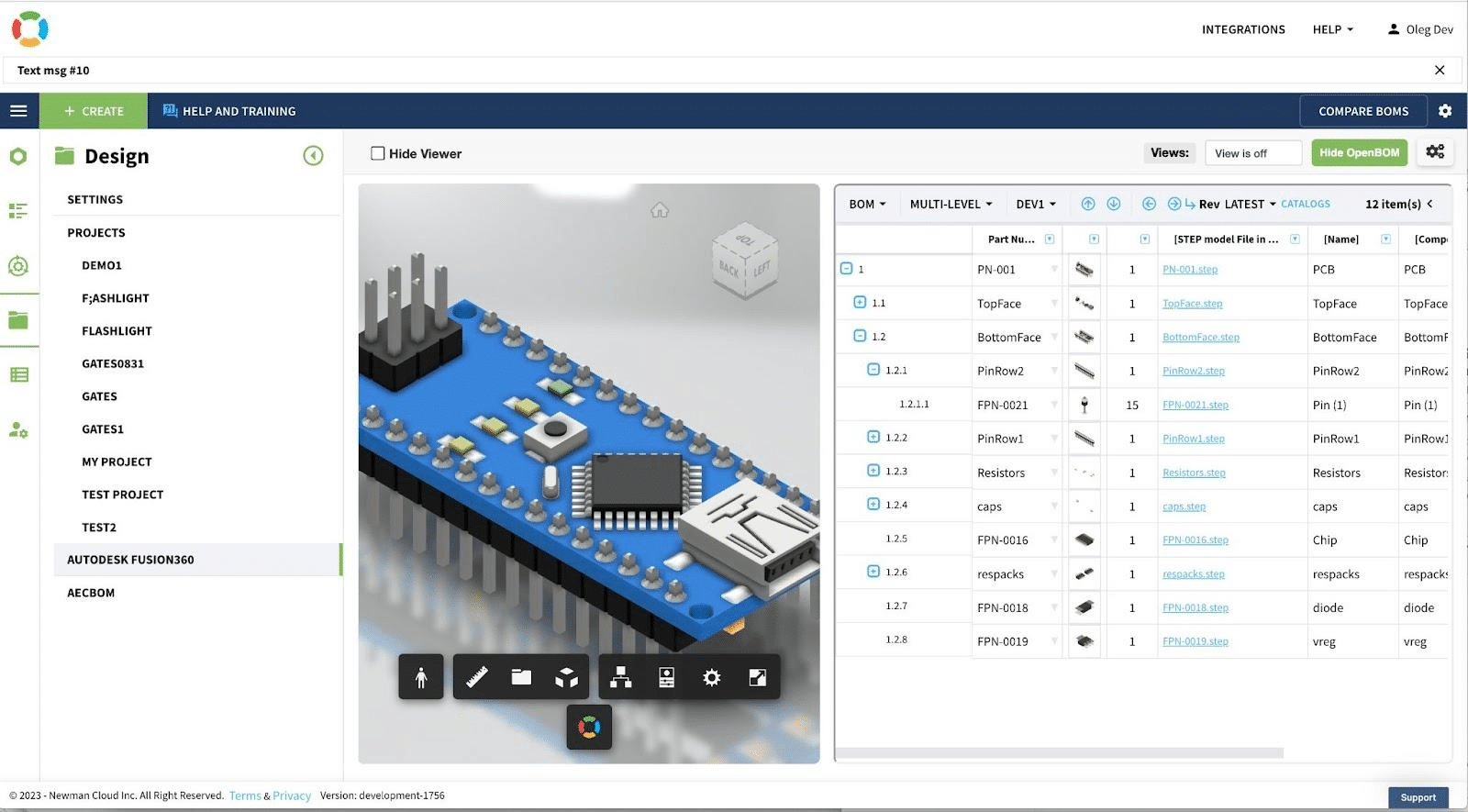

In the picture below, you can see a new service integration between Autodesk Fusion360 and OpenBOM allowing seamless transfer of data between both environments and streamlining production planning and development process.

Read more about it in the earlier OpenBOM blog – Data Granularity and New Product Development process. The following passage describes the core problem of inefficient communication and how OpenBOM helps Autodesk customers solve it.

OpenBOM Agile New Product Development

At the core of the OpenBOM business, we focus on how to accelerate the product development process and new Autodesk CAD integrations play a very important process in streamlining data exchange. However, this is just the beginning of the new product development process. The value of data extraction is big, but the next steps are also important.

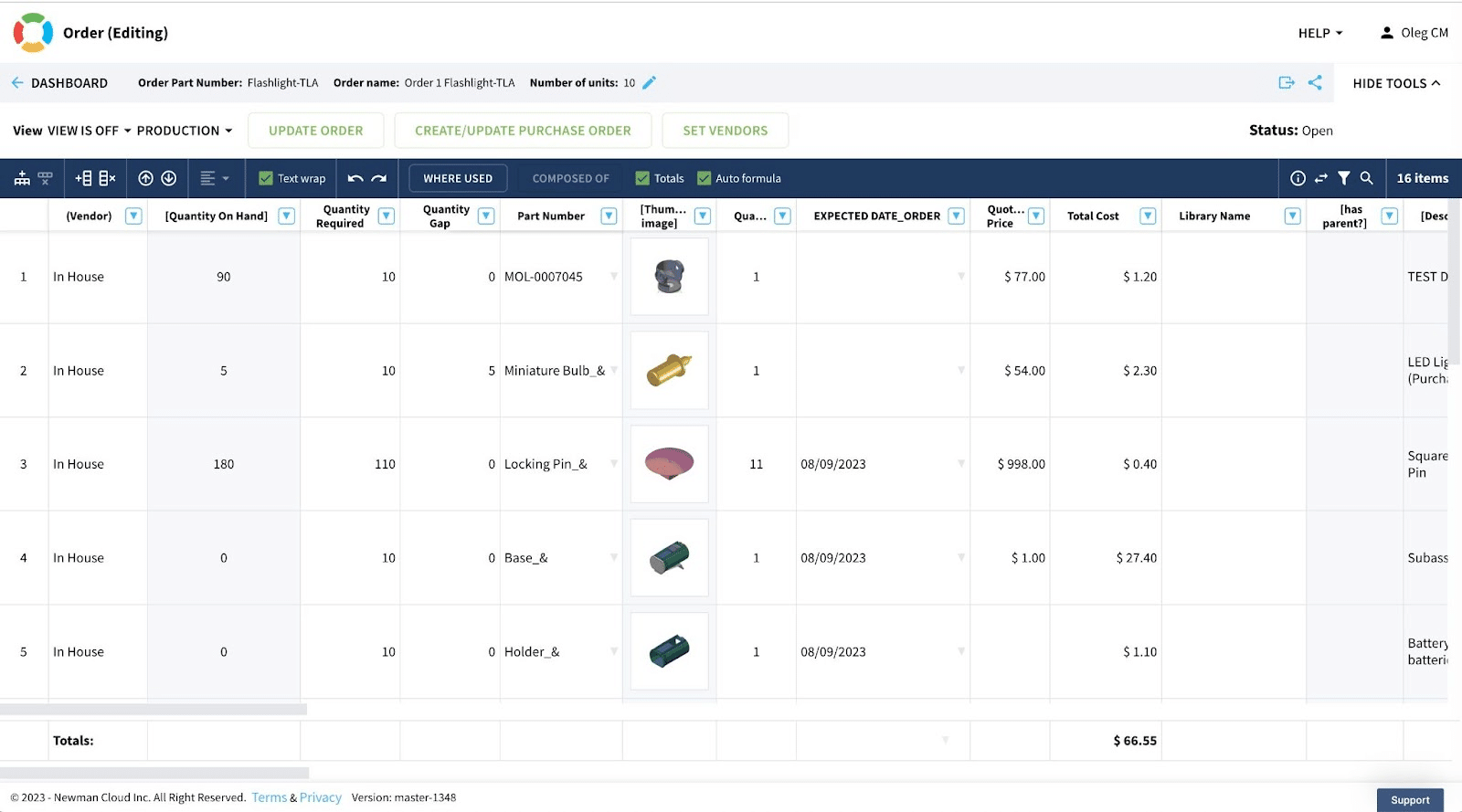

OpenBOM New Product Development solution (which you can easily characterize as ‘design to make’) includes four steps – (1) Design; (2) BOM; (3) Purchasing; (4) Assembly. Here is an example of the purchase ordering process seamlessly created from Autodesk Fusion 360 data and additional information added into the BOM.

At OpenBOM, we recognized a substantial inefficiency in managing this process using Excel and Email and suggested establishing an agile process of setting up data that can be used by everyone to collaborate and move the process forward.

It is important to emphasize the complementarity of both services. While Autodesk Platform Service (APS) data API enables access to the data, OpenBOM Collaborative environment allows the same customers to escape the traditional “Excel path” and to collaborate with the data in a real time.

OpenBOM patented collaboration methods allow sharing of data in real time (a-la Google Sheets) and access and edit data by multiple users respecting access control rules and only making correct information available. It saves a lot of time and eliminates the need to share data using traditional Excel spreadsheets with file attachments. All data is seamlessly integrated and organized into OpenBOM including product structure, dependencies and file attachments. Check for more information in the following article – OpenBOM Shared Views For Instant Supplier and Contractor Collaboration. The following video is the key:

Conclusion

OpenBOM platform supports flexible data management and seamless real-time collaboration between teams of engineers, production planners, and procurement organizations (suppliers and contractors) allowing to share data in real-time and keep everyone in sync. That is a huge difference compared to a traditional “Excel” or even Google Sheet collaboration. OpenBOM’s flexible data management platform allows the organization to organize product data information with all links, hierarchical relationships, and files together eliminating the need to deal with Excel and email/file attachments.

Combined with the powerful capabilities of Autodesk Platform Services (APS) data API, OpenBOM allows seamless data connection and integration that empowers manufacturing teams and supports agile product development methods.

Learn more about recent OpenBOM announcements about Design Projects, Custom Objects and Integrations here.

REGISTER FOR FREE to check how OpenBOM can help you.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.