In the modern dynamic landscape of product development, the release process is a crucial and complex element that can determine the success or failure of a product. Modern products often encompass a blend of mechanical, electronic, and software components, making the release process multifaceted and challenging.

The traditional methods of managing releases were based on the PDM approach that was centered around CAD file released, which was mostly single CAD system oriented (eg. MCAD) and it lacks the flexibility and collaborative features required to handle the complexity of today’s products and distributed nature of engineering teams

At OpenBOM, we invented new collaborative methods focusing on real-time collaborative editing, automatic history tracking, capabilities to integrate multi-disciplinary item/BOM structure, and allowing us to work with multiple CAD systems (desktop and cloud) at the same time.

In this blog, I’m starting a set of articles about the agile engineering release process. You will learn about the basic principles of the OpenBOM change management process and later dig into detailed instructions on how to organize it and also details explaining how the OpenBOM change process is different from traditional CAD file-based release.

Agile New Product Development and Release Process

The trend towards agile new product development is transforming how products are brought to market. This approach emphasizes the importance of collaboration among diverse teams working on mechanical, electronics, and software aspects of a product. Providing these teams with visibility into the supply chain and manufacturing processes simultaneously is crucial for efficient product development. OpenBOM’s release and change management process is designed to facilitate this level of collaboration and visibility, distinguishing itself from traditional systems.

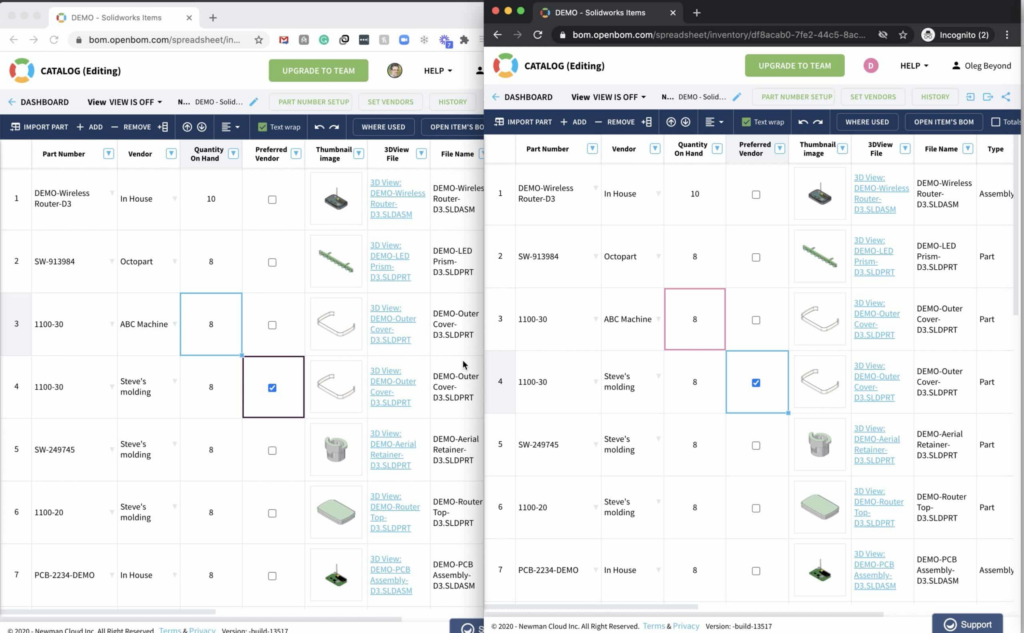

OpenBOM collaborative editing allows to provide simultaneous access to edit product structure by multiple people in the organization, while presenting it to users with a simple “a-la Google Sheet” user experience, as you can see on the picture below. Behind the simplicity, OpenBOM runs a sophisticated product knowledge graph model. So you get a simple spreadsheet with a big portion of PLM steroids.

Multiple users can access the information in “latest state” and perform edits. Eg. change data, add items, attach files, modify the structure. The editing can be done manually by users (think engineer editing descriptions or procurement person adjusting suppliers) as well as automatically by pushing data using CAD Integrations.

The collaborative user experience is similar to what you’re familiar with in Google Docs, Microsoft Office 365, and other similar products. You can see a “spreadsheets on steroid” powered by OpenBOM patented collaborative methods.

The foundation of the OpenBOM release process is a flexible graph-based model of a product structure capable of holding reference-instance relationships (aka BOM) and allowing multiple actors (data sources and engineers to make changes simultaneously).

Moving from Design (Document) Driven Process to Granular Product (Data) Driven Process

Traditional release processes are often document-driven, with CAD files serving as the foundation. Each file is revised and eventually released, forming a design BOM that is then released. OpenBOM offers a more advanced approach by shifting the focus from document-driven to granular product data-driven processes.

The core of this methodology is item organization with the xBOM system and a collaborative editing process. This approach ensures that the “latest state” is always available for simultaneous editing by all team members, enhancing real-time collaboration and accuracy.

In the picture above, you can see how PN-001 [ Latest] is a graph representation of product structure together with all connected information and multiple people can make changes. Once the [Latest] workspace approach the level of maturity ready for “release”, the command “create revision” makes an immutable snapshot of the graph and store it as a revision.

Document (Design) Control with OpenBOM

For CAD-driven processes, OpenBOM offers robust document control through Design Projects for file-based CAD systems or separate controls for cloud-based CAD systems. Engineers working on MCAD and ECAD can iteratively version CAD files, which are then captured by the Item/BOM system to form a comprehensive, multi-disciplinary product structure. For cloud-based CAD systems, OpenBOM connects directly to versions of design (eg. PTC Onshape, Autodesk Fusion, or Altium 365). This integration ensures that all aspects of the product are cohesively managed and updated.

Here you can see the overall picture of connecting all multi-disciplinary data into a single graph of connected information forming OpenBOM Design Digital Thread.

The Release Process with OpenBOM including Change Orders and Revisions

The release process in OpenBOM reaches a critical point when the Item/xBOM structure matures. At this stage, OpenBOM captures the entire structure, including CAD file versions and all associated derivatives, and snapshots it as an Item/BOM revision.

Simplicity is a key and, therefore, OpenBOM provides two ways to manage revisions – (1) simple; (2) controlled. In the first (simple) method, an end user can activate the “create revision” command to save revision, as I explained in the previous chapter.

The second (controlled method) is more structured. As you can see on the picture below it allows to create so called revision candidates (change requests) and create revisions using collaborative approval-driven workflows, where users can approve / decline the change order. We will be discussing these workflows in the next article.

Best Practices for Release Management with OpenBOM

In the picture below, you can see the overall process of engineering release in OpenBOM, which covers four basic stages – (1) CAD versions, (2) BOM Edit, (3) Change Order; (4) Revision creation. The picture below shows you the four steps and gives you a high-level overview of how it works.

- Use Design Projects for CAD Versions or Cloud-Based CAD: Manage and control CAD file versions effectively within Design Projects or through separate controls for cloud-based CAD systems.

- Save Items and BOM and Capture Files: Ensure that all items and BOMs are saved, and files are captured accurately to maintain the integrity of the product data.

- Review “Latest” State and Make Edits Collaboratively: Regularly review the “latest” state of the product data, making collaborative edits to ensure accuracy and completeness.

- Create Revisions or Approve Change Orders (CO): When the product structure reaches maturity, create revisions or follow an approval-driven process to finalize the release.

The picture below shows you the overall structure of data objects responsible for the engineering release process.

Demo- A Day in the Life with OpenBOM

In the following video you can watch the video demonstrating OpenBOM engineering lifecycle. Check this out.

Conclusion

OpenBOM offers a collaborative, data-driven approach that integrates all aspects of product information and organizing a structured release management process . The so called “collaborative latest state” brings the same ideas used by modern cloud collaborative systems such as Google Docs, GitHub, and Onshape and uses the same approach for collaborative product structure editing process combined with design iteration and approval/revision process.

This system effectively intertwines CAD work-in-progress version management with an item-driven release process, providing a streamlined and efficient method for managing complex product releases. By adopting these best practices, teams can ensure a smoother, more accurate release process, ultimately leading to better product outcomes.

This approach combines the best sides of both words, management of CAD files for versioning, and a complex product structure collaborative editing process. In my following articles, I will demonstrate each of these four stages and explain how it will work in greater detail.

REGISTER FOR FREE and see how you can use OpenBOM to change your release management process.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.