If you’re in manufacturing, you know the importance of having an organized process for releasing new products. In order to stay ahead of the competition, manufacturing companies must turn to release processes that allow for quick changes and updates to products. The process must be optimized, including the orchestration of multiple parties – engineering, contractors, procurement, and suppliers. Companies are continuously looking for methods that can help them to streamline data handover between engineering and manufacturing, to customize their product releases quickly and easily while still maintaining a high level of quality control.

With OpenBOM, manufacturers can manage all aspects of the product release process, from design and prototyping to final production and delivery. By using OpenBOM, companies can ensure that they are always releasing the best possible products in a timely manner. OpenBOM allows you to manage your product data, bill of materials (BOM), and all related information including files, specifications, and materials in a central location, making it easy to keep track of changes and releases while allowing easy data sharing and communication across multiple companies.

OpenBOM is a cloud-native software as a service (SaaS), which allows you to access data anywhere as well as make the information shareable and collaborate with companies regardless of what company they work for and what geographical location they are. Seamless integration with CAD and other software allows you to extract needed information. Patented data collaboration mechanism allows instant data sharing and simultaneous information access.

Product Release Process Support

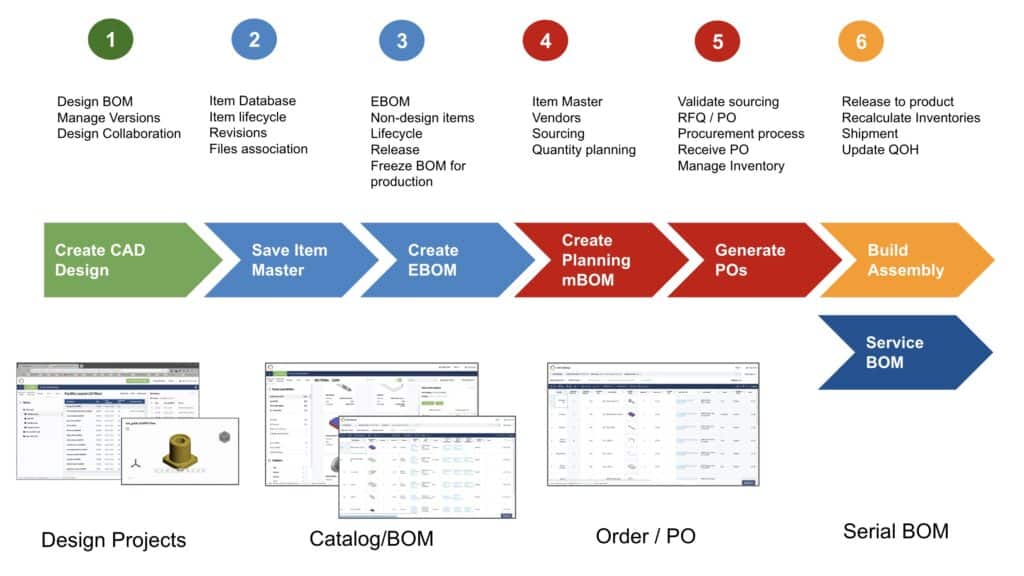

In the diagram below, you can see OpenBOM functions available to support manufacturing companies in all stages of the product release process.

OpenBOM tools allow the team to maintain a cohesive set of information for all stages of product lifecycle management and iterate with the product development and future changes.

Design

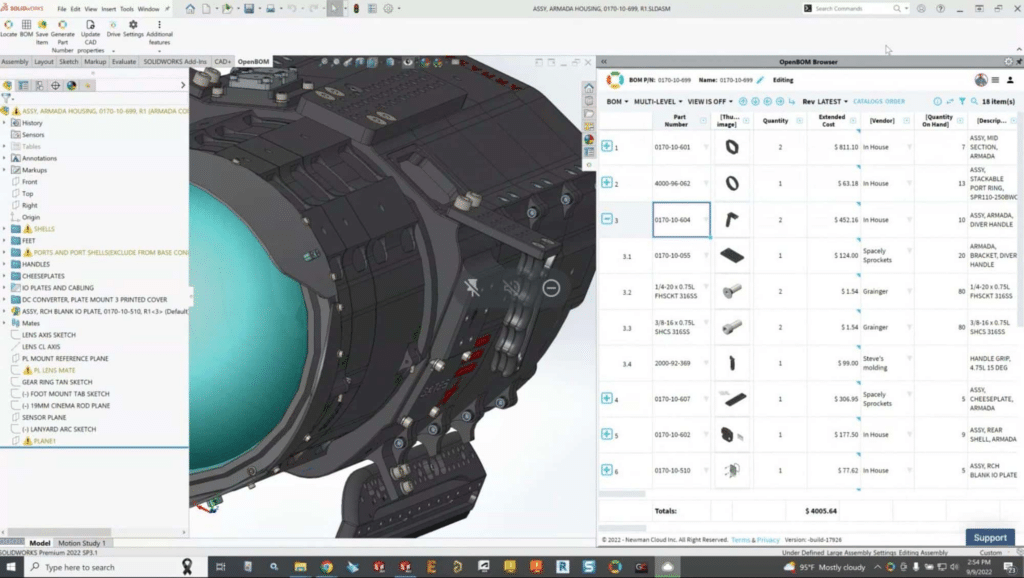

OpenBOM supports your design activities by providing integrated tools for any CAD software you use to capture information including metadata, product structures, BOMs, files, and everything else you need to get data from design to starting your production process. Here is an example of OpenBOM integration with Solidworks. Check OpenBOM documentation and training about other CAD tools support.

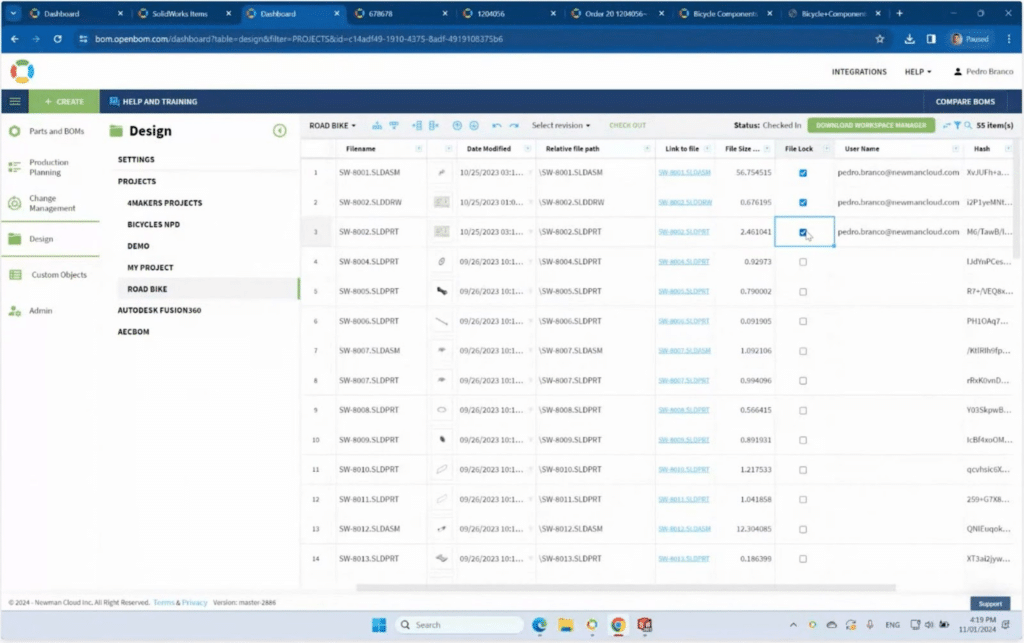

To help manage file versions, OpenBOM Design Projects provides you with PDM functions that allow you to manage CAD files versions including unlimited cloud storage, cloud sync, file locking and version control including seamless collaboration between engineers.

BOM Management and Collaboration

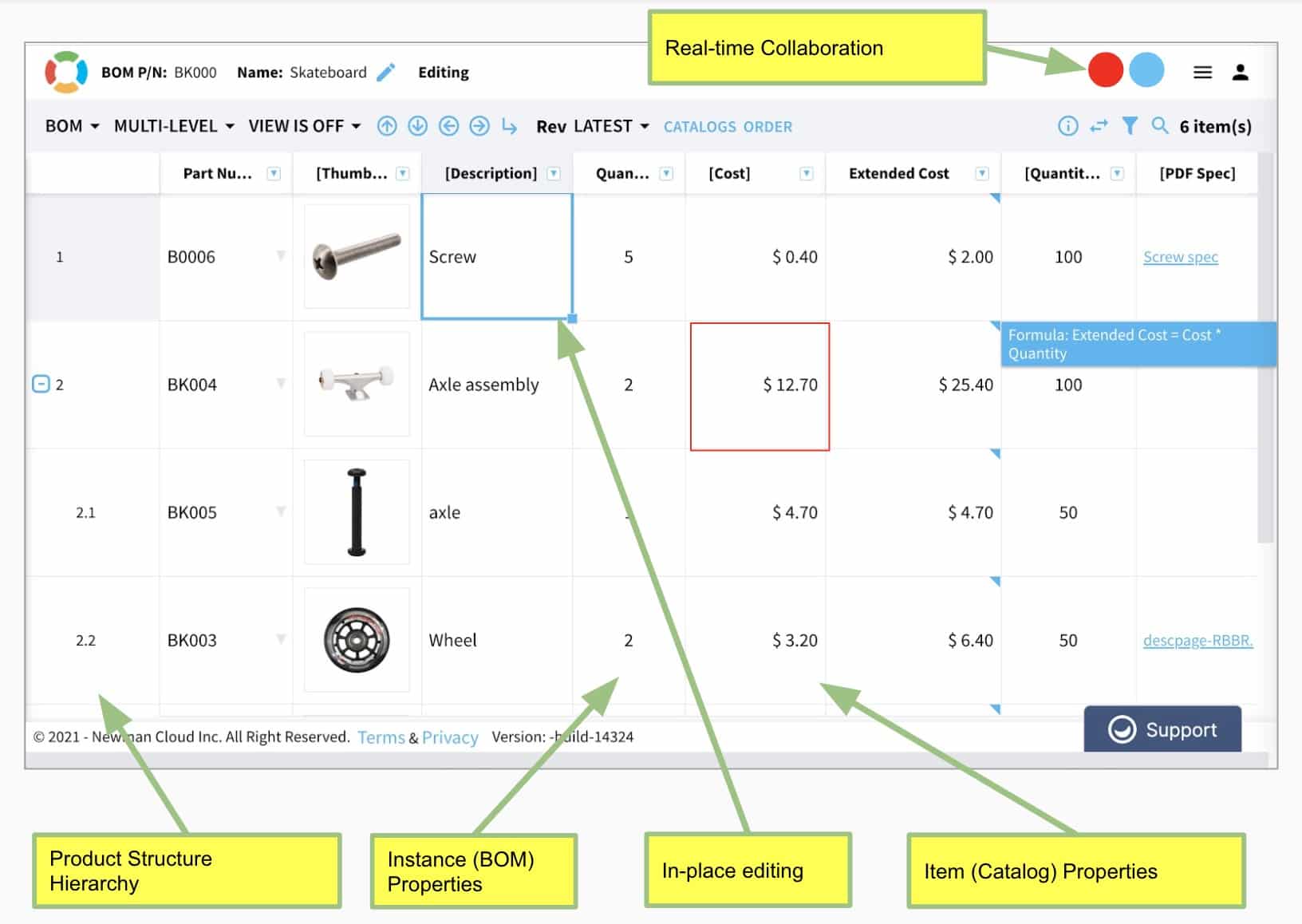

OpenBOM manages items, bills of materials, history of changes, revisions and allows you to create a complete product data representation. The data initially extracted from CAD systems can be used to collaborate between engineering teams, ensure the completeness of information, manage revisions, ensure it has a full set of files, specs, material documentation. The information is structured and shared with initial planning for contractors, CMs, and suppliers

Analytical functions such as rollups, calculations, and others allow you to make cost assessments as well as to communicate with all teams to validate data completeness.

Team collaboration and granular access control allow sharing data with a right view on the information (eg. engineering, manufacturing, procurement, planning, suppliers, etc).

Easy functions to export data to Excel, PDF, and ZIP files allow you to collaborate with people using OpenBOM as well as anyone else.

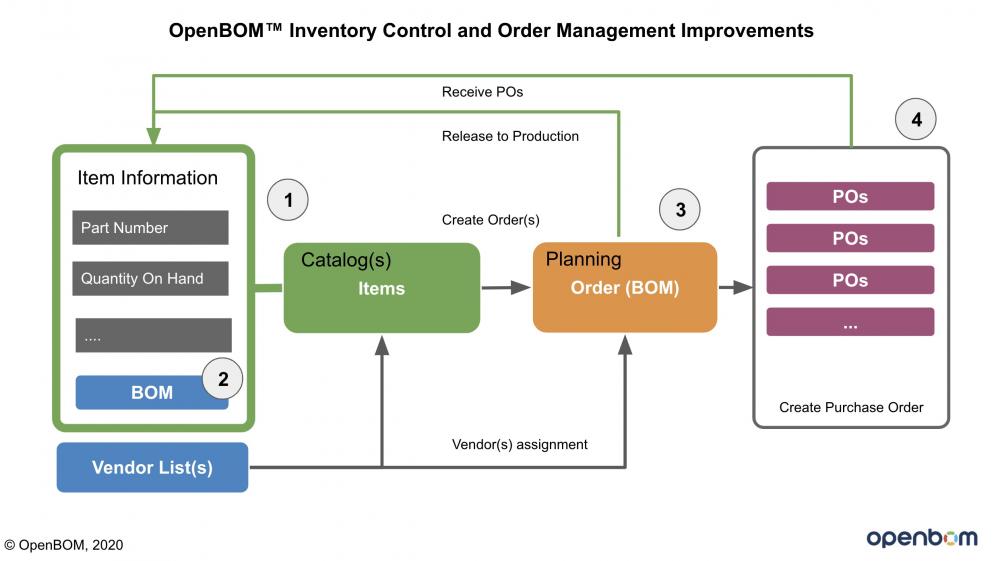

Planning, Inventory, Sourcing

Mainstream and legacy PLM software always underestimated the needs of the team to be integrated. The connection between engineering and manufacturing processes is a huge pain in all PLM packages. OpenBOM provides a unique set of functions to manage inventory, vendors, and procurement processes. Such functions are extremely useful for agile development teams because it allows performing planning and development in parallel.

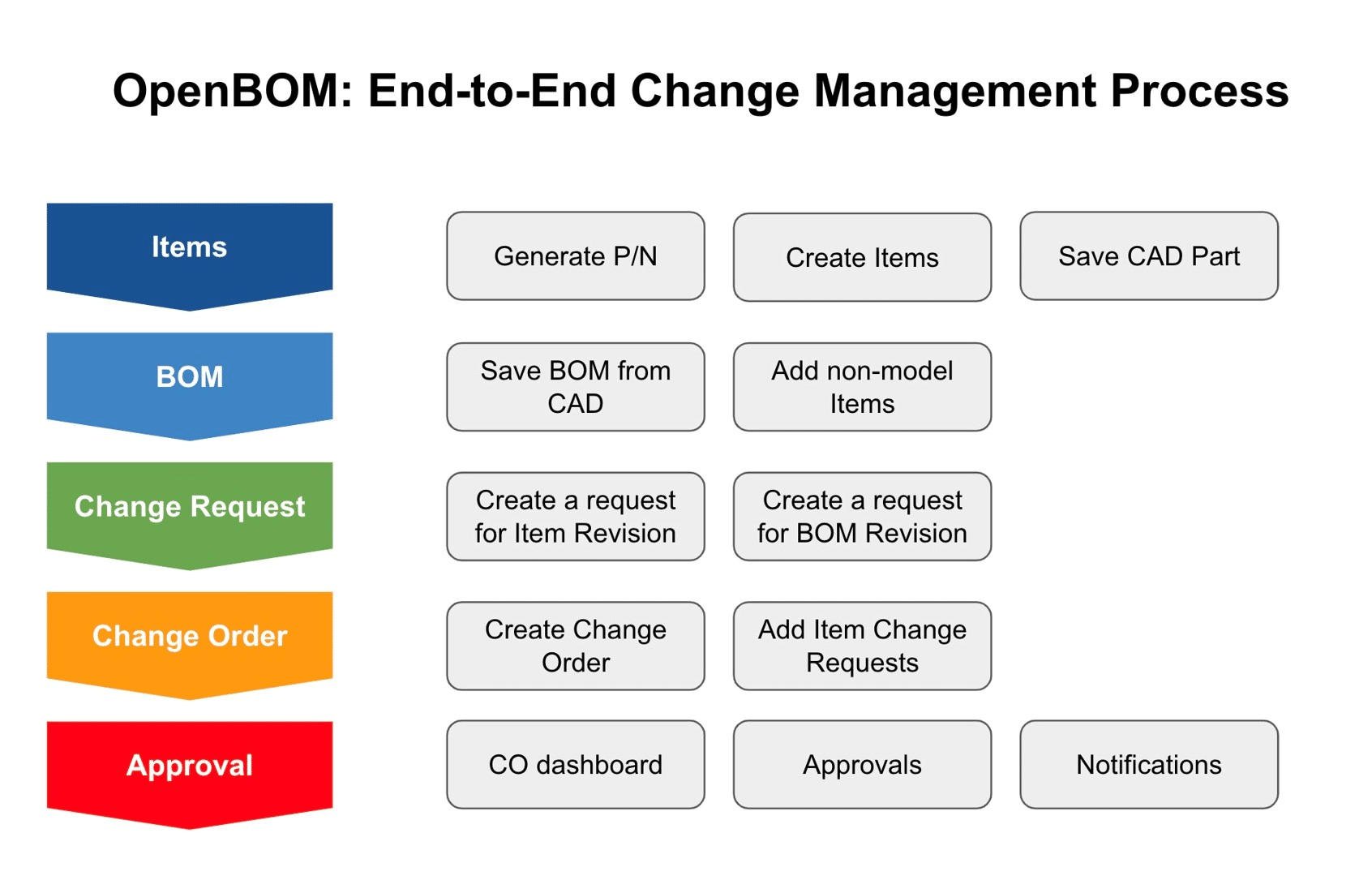

Change Management

Change is the only constant thing we have in engineering and product development. The ability to establish a formal change control, but provide a flexible and transparent mechanism to manage the approval process is another part of OpenBOM’s innovation.

A unique collaborative approval workflow is the way to do so. It allows you to organize changes and involve the right people for approvals. However, the process is flexible and collaborative, which is extremely important for agile development teams.

Conclusion

OpenBOM product lifecycle management platform provides support for the entire product lifecycle process but specifically focuses on how to organize a seamless data handover between design, engineering, manufacturing, and supply chain. Unlike mainstream PLM platforms capable of supporting only large enterprises and requiring complex integrations with other tools, OpenBOM provides an integrated mechanism for data management related to multiple disciplines (mechanical, electronics, software development) as well as on integrating product development stages (design, engineering, procurement) together. Seamless CAD integrations and unique collaboration tools help you to get access to a single source of truth about the product for everyone and connect silos regardless of their organizational belonging (OEM, contractor, suppliers, etc).

Check out how OpenBOM can help you – REGISTER FOR FREE and start your 14-day trial period to evaluate OpenBOM. We provide online support as well as training online and a dedicated onboarding experience to help you during this journey.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.