As a manufacturer, sharing product data with your contract manufacturer (CM) or supplier is one of the most important and also routine tasks to do. The product data can be CAD files, Bills of Materials (BOMs), component specifications, or anything else related to your product. But whatever it is, the information you provide your supplier must be accurate. If not, then you risk producing wrong parts, delaying production, making changes to wrong parts, and more.

While the data you provide to your supplier is very important, manufacturers most often use Excel or Google Sheets as a tool to share data with their suppliers. The simplicity and familiar look have made it the go-to tool for managing data across all industries and is the main tool to pass data from one party to another.

But beneath the seemingly user-friendly interface lies a tool that can comprise the integrity of your manufacturing process. While Excel offers convenience and flexibility, it also has some limitations that may not be apparent until engineering, procurement, and production mistakes are made.

Therefore, with the benefits of Excel, is it worth using it as a tool to share the production data you have worked so hard to create with your supplier?

Limitations of Excel

While Excel is a versatile tool, it does have several limitations, particularly when it comes to managing and sharing complex product data. Here are four key limitations of Excel when it comes to sharing data with your supplier.

Limitation 1: Version Control

Managing version control in Excel can be challenging, especially when multiple users are involved in editing and updating the same spreadsheet. Without a centralized system for tracking changes and managing revisions, it’s easy for conflicting versions of the data to be circulated. This leads to confusion and inconsistency in communication with suppliers.

Limitation 2: Collaboration Feature

While you can collaborate with Excel files, there is no real-time visibility into who is making changes or what modifications were made and for what reason. This lack of transparency can hinder communication and coordination with suppliers.

Limitation 3: Scalability

While Excel might work for smaller projects, it’s not suitable for managing large volumes or complex datasets. As the size and complexity of the data increase, Excel will be more vulnerable to mistakes.

Limitation 4: Weak Integrations

Excel was not created to be integrated into manufacturers. It was not designed to integrate seamlessly with CAD, ERPs, and other business tools. This lack of integration with manufacturing tools will lead to an increase in data silos leading to more mistakes and inefficiencies.

Alternative Way of Sharing Data with Your Supplier

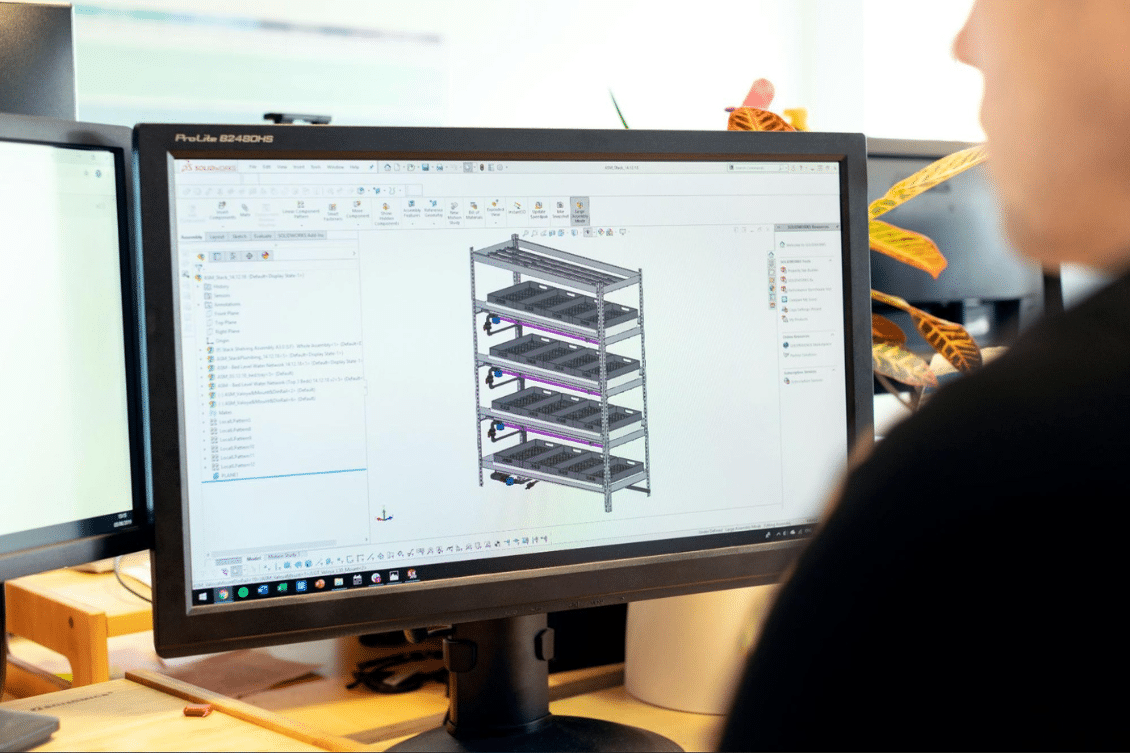

While Excel has been the go-to tool for managing and sharing data, there are alternative solutions that offer more capabilities. Manufacturers have started to see the importance of digital tools to enable collaboration and efficient data sharing. These tools are not just important for their internal processes but help to establish better partnerships with their suppliers and can help take you from concept to shipping quicker.

Here are four things that you can improve by digitalizing your processes.

Accuracy and Consistency

If you are digitizing your processes, you are creating a single source of truth. This single source of truth is a platform where the latest data will be shared and the previous revisions and historical data will be stored. All of the product data being stored in the same place will eliminate data silos which reduces the likelihood of errors and rework.

Real-Time Collaboration

These alternative solutions to sharing data with your supplier allow for seamless collaboration and communication. Changes in the BOM and product data can be shared instantly, ensuring all parties have access to the latest information in real-time. This automatically improves transparency and enables quicker decision-making time.

Improved Supply Chain Visibility

If you are looking for alternative solutions by digitalizing your processes then you’ll have greater visibility into the supply chain by centralizing info about all components. Manufacturers will be able to better track inventory levels, monitor production schedules, and identify potential bottlenecks or delays in the supply chain.

Enhanced Traceability

Excel struggles to offer traceability of components and materials throughout the manufacturing process. By capturing detailed information about each component, such as supplier, specifications, compliance requirements, etc, manufacturers can ensure regulatory compliance and meet quality standards more effectively.

Conclusion

Companies are looking for ways to differentiate themselves. However, oftentimes, they use tools, like Excel that were not created to store your product data.

Digitalizing your processes will help you to transform your processes and help you share data with your supplier. To have a centralized platform that connects your team with your contractors is extremely important to set up modern digital processes to save time and money.

OpenBOM is a cloud-based PDM & PLM platform to manage your engineering and manufacturing data. Companies from startups to Fortune 500s use OpenBOM to create a centralized database to bring in, store, and manage their manufacturing data. With this infrastructure, users also use OpenBOM to streamline both their change management and PO processes.

If you need to improve the way you manage your data and processes, share data instantly, or collaborate with contractors and suppliers, Contact us today for a free consultation.

Regards,

Jared Haw

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.