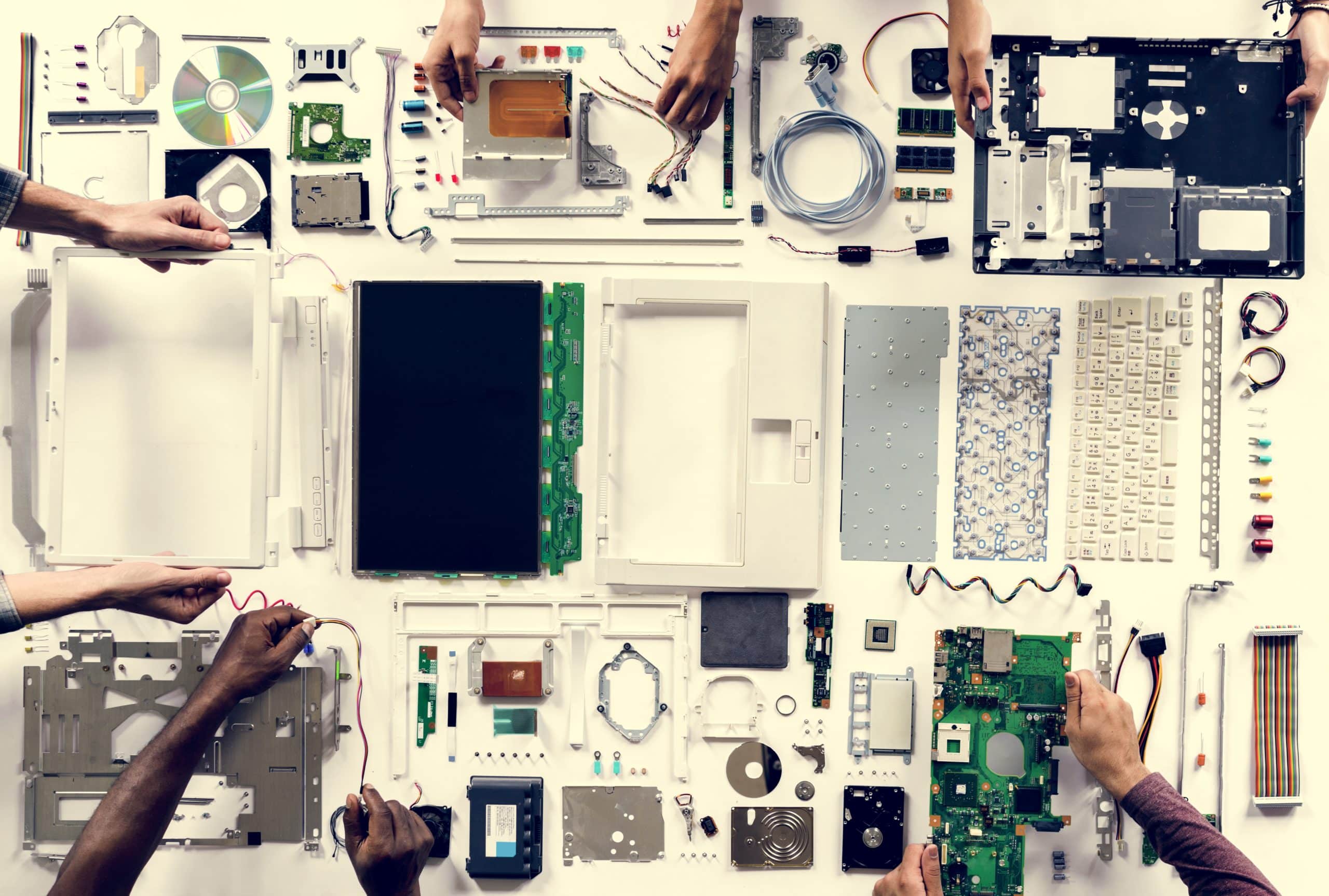

Whether you are trying to launch a new product, improve your supply chain/manufacturing operations, reduce your cost of goods sold (COGS), or send out an RFQ package, your bill of materials (BOM) will be the center of it all.

A BOM is a centralized tool containing your product information, it is also the foundation to launch and scale your operations. Launching and scaling a product without a BOM is like building a house without a solid foundation. It will just collapse on itself.

Why is a BOM so critical?

Simply put, if your BOM sucks, your product will most likely suck. This is because the BOM holds the knowledge of what you are manufacturing. Having a detailed BOM will provide you with data to support important decisions. These will include:

- Which item to cost down – With a transparent BOM quote, you will be able to clearly understand your COGS. When your costs are transparently laid out, it is much easier to target the low-hanging fruit and start your cost-down project.

- Inventory Planning – If you understand your lead time for each part and assembly, you can accurately plan how much inventory you need to store in your warehouse and when you should purchase parts or products.

- RFQ Package – Since the BOM holds the knowledge of manufacturing a product, all of your requirements, specifications, drawings, and other information have a place linked in the BOM. So, your RFQ package becomes quite simple and you can decide quickly whether or not you need to change your supply chain.

These are just a few of the things that a detailed BOM can help you achieve. However, how do you get to this point? Ensuring the BOM is as descriptive as possible is the first step. Below are some of the columns you will find on the BOM along with the biggest problem I have seen with them throughout the years.

What to include in your BOM?

Part Number: Each part or item should be assigned a unique part number.

- Biggest Problem: duplicates of item numbers. Each unique part should have a unique number associated with it. Please don’t double down on these, it just adds confusion.

Material: This is just the material type and grade of the material.

- Biggest Problem: Please never say just plastic. You must define the plastic, such as ABS. Also, it’s not just aluminum. What kind of grade of aluminum? Such as aluminum 6061-T6

Color: This is similar to material. You need to call out a pantone number or the appropriate coloring system your supplier uses. There are many different shades of each color. So, it must be defined clearly because light blue and dark blue are both blue.

- Biggest Problem: It’s not blue, green, or yellow. You need to use codes that identify the exact shade. Such as Pantone Green C, Pantone 292U, etc.

Finish/Texture: One of the more important aspects, aesthetically, is the finish and texture. This can be the difference between the end-user purchasing the product and not purchasing it.

- Biggest Problem: Not correctly specifying this. Providing pictures, videos and samples will help explain what you want. This is true especially for items that might be a bit subjective, such as PC plastic that is 40% transparent.

Unit: What is the unit of the item you are defining. For example, if it is going to be a plastic part then it will be a number, such as 4. Other items, such as lubrication will have a different unit because usually, you don’t do 3 units of lubrication. It will be mg, grams, oz, or whatever the unit of measure is.

- Biggest Problem: For certain items, make sure you specify the unit. Don’t say you need 4 units of glue for assembly, how many grams are needed? Also, for webbing, specify the length of it, such as mm, inches, yards, etc…

Lead Time: When managing a project, you should not manage the date of the final assembly. You manage each individual part and item. This means understanding the lead time associated with each individual part and item.

- Biggest Problem: Unfortunately, this column is usually left blank with a final lead time at the end. But don’t you want to know the lead time for each part or item? What if there is a delay with one item, would it affect the lead time of final assembly and thus shipment? In order to plan and forecast, it’s a good idea to have a lead time associated for each item. Even if there is a quality problem, you can understand how it will affect the overall lead time.

Clearly defining the BOM before launch and scale-up is as basic as creating the foundation before building a house. Unfortunately, many people are getting by with a poorly defined BOM. The good news is that it’s not too late and you can easily improve your BOM to improve your overall operations.

Conclusion

OpenBOM creates, manages, and shares your EBOM. OpenBOM believes engineering, supply chain, and manufacturing teams should be able to seamlessly manage their parts, vendors, bill of materials, purchase orders, and change orders. All BOM, engineering, and manufacturing information are stored in the cloud which you can share with your team, contractors, suppliers, or anyone else that has access to your account. OpenBOM keeps everyone on the same BOM while providing you with the tools to streamline your development in production & scale up operations.

Register for FREE to create your OpenBOM account and reach out to us via support @ openbom dot com if you have any questions.

Regards,

Jared Haw

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.