Simplicity is hard. At OpenBOM we’re continuously looking for ways to improve user experience and streamline processes of how data can be entered and created. Today, I want to focus on Bill of Materials creation and how you can optimize and streamline this process by interplaying both new part number generation, adding a new item, and creating a BOM for this item. Before jumping into the process, I want to refresh your memory about the OpenBOM data model.

Item and BOM Data Model

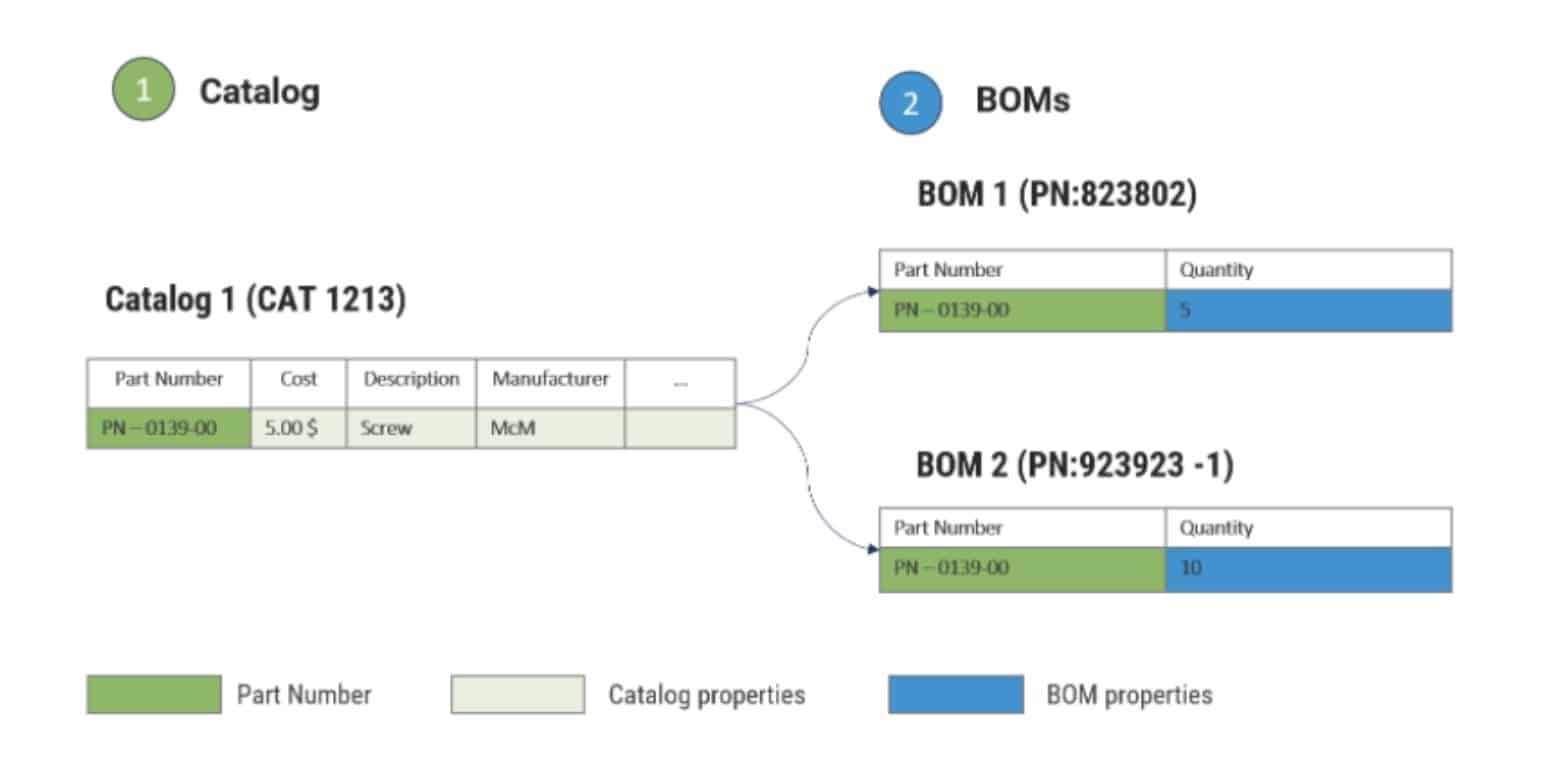

A fundamental part of the OpenBOM database is the Item and BOM data model. If you missed that, check the Getting Started: Understanding OpenBOM section in the Training Library. And the following picture gives you a quick overview – Item (is a catalog record) that is used (instance) in multiple BOMs.

So, if you think about objects, a BOM is an object added to the Item (in such a way, Item will be considered as an Assembly).

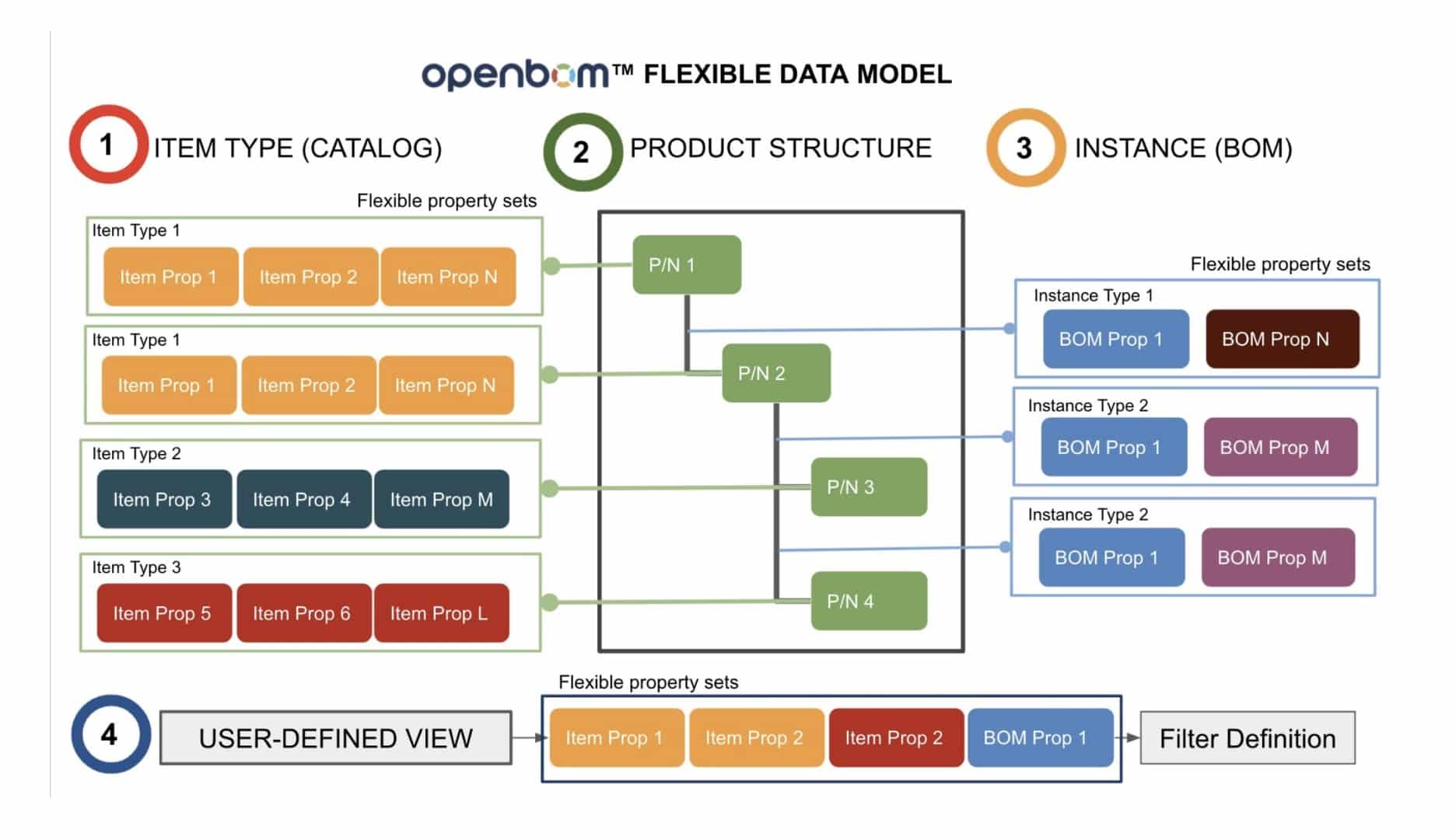

In a more comprehensive data modeling diagram below you can see the flexible OpenBOM Data Model that explains how data objects can be customized and expanded for different item types and different BOMs. In such a way, you can create a multi-disciplinary BOM structure combining mechanical, electrical, and software components.

Generate Part Number and Create a BOM

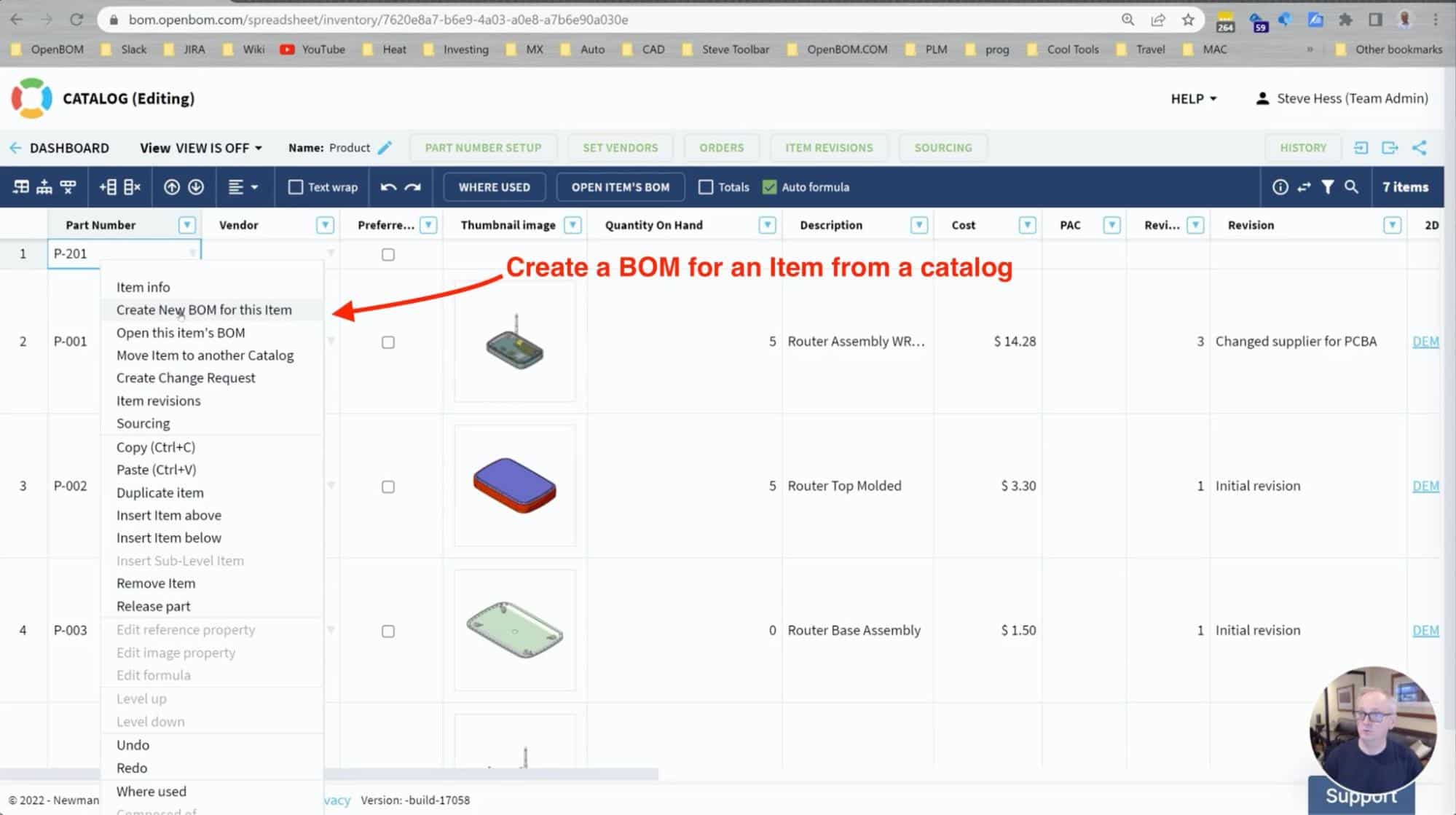

In this scenario, we demonstrate how to add an item to a catalog, generate a new Part Number automatically and create a BOM. The first step is in the catalog. You add a new item and by doing so, a new Part Number will be generated.

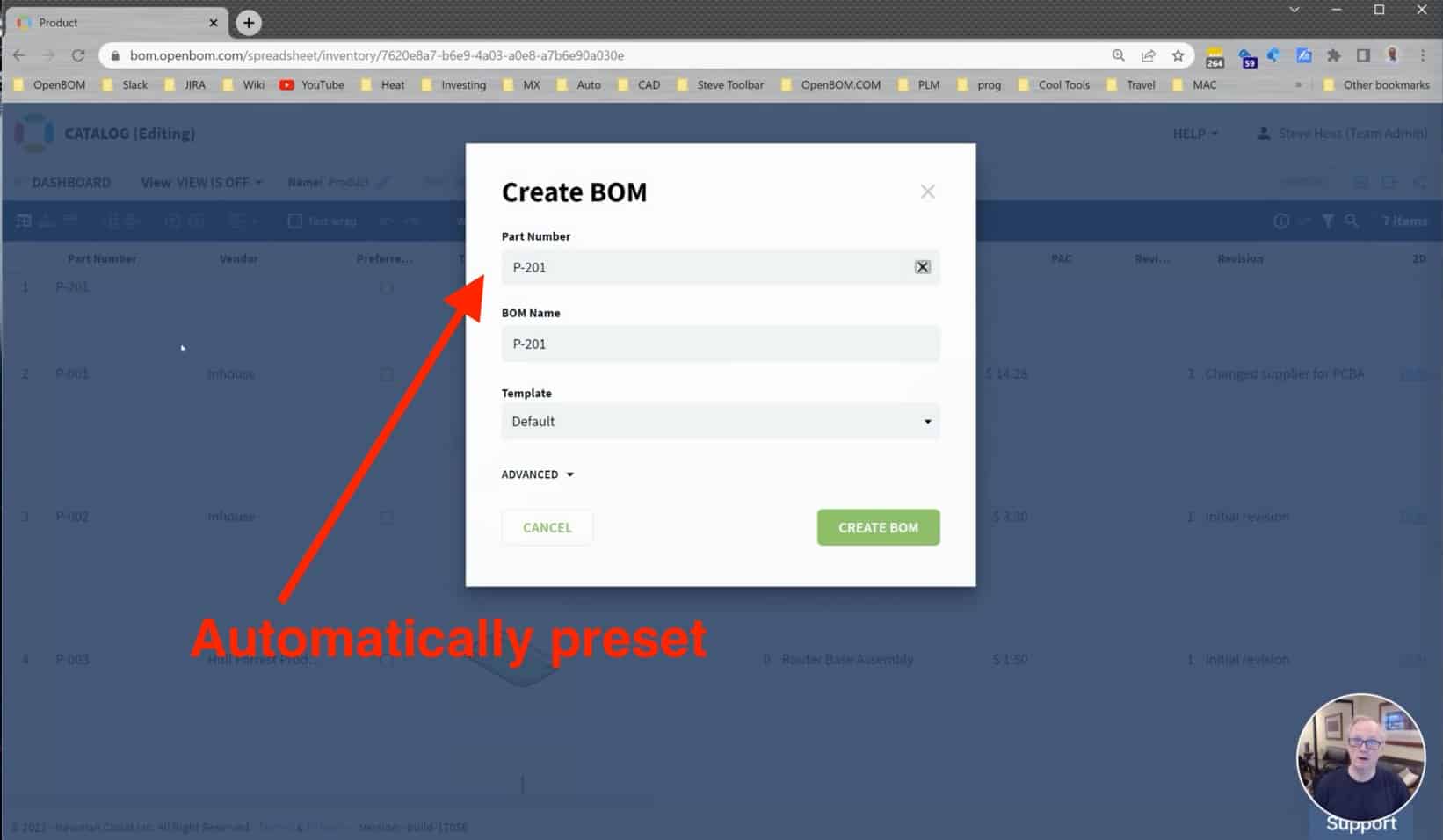

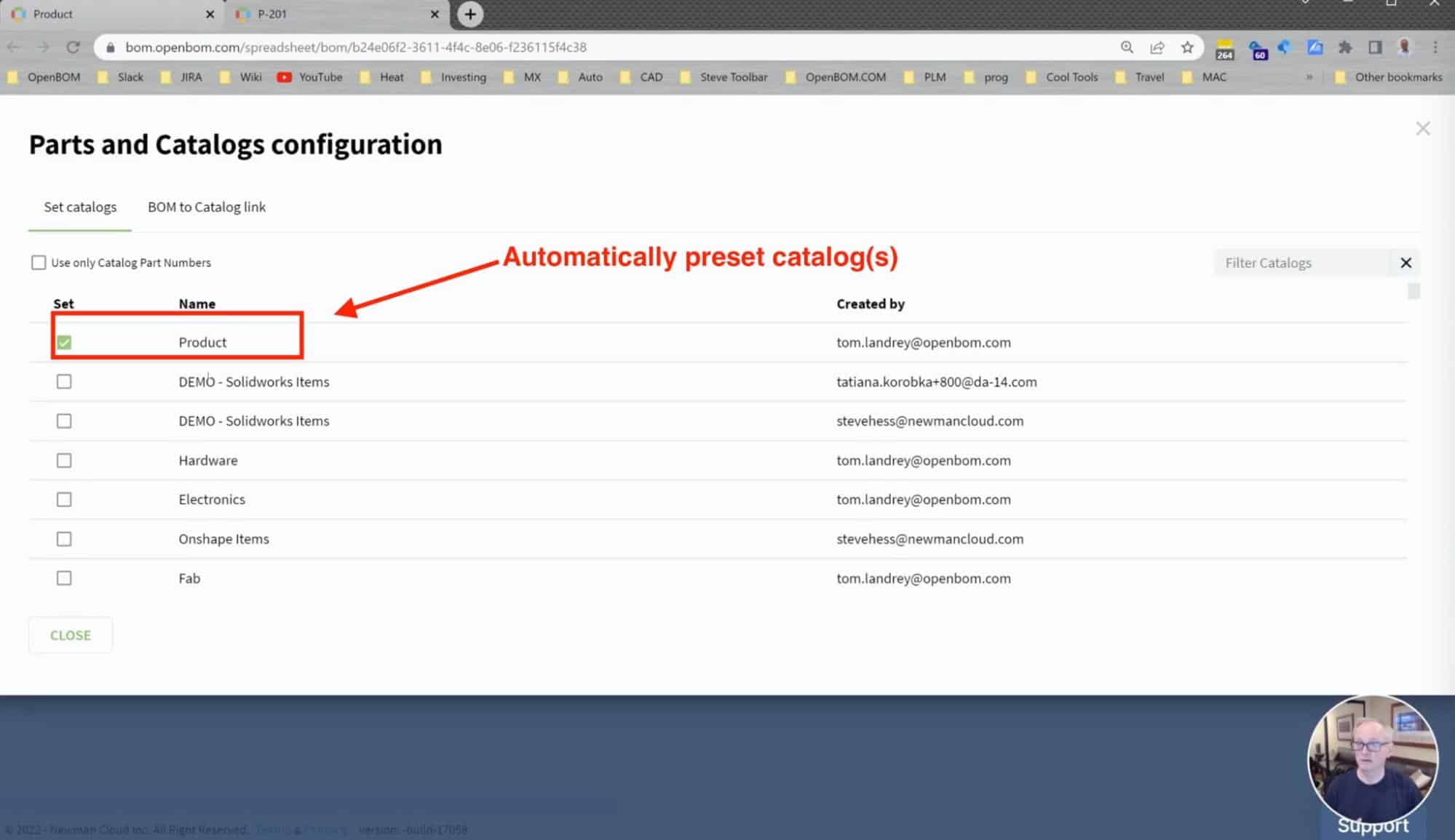

Once a new Part Number is added, you can use the “Create a BOM” command, and a Create BOM dialog will come up with preset catalog and Part Number settings.

That’s it – so simple. By following the steps, you can easily add multiple assembly items and follow by adding a BOM and adding parts.

Video Demo

Watch the video that demonstrates the process I described above.

Why Stop Thinking about BOM as an Excel?

“If the only tool you have is a hammer, you tend to see every problem as a nail. Many OpenBOM customers are coming from the Excel world where the solution (BOM) is an Excel and there is no database of Items. Switching to OpenBOM many of these users continue thinking about BOM management as an Excel-like process of creating BOMs.

This is a place where we recommend you make a mental shift. Start to think about databases, items, attributes, and then BOMs. Check the following article – Why do you need to think about Items and Not BOMs First?

Conclusion

Seamless user experience is important. In this example, we demonstrate to you a very basic process that can save you tons of time and simplify the process. A fundamental element of the OpenBOM data model is an item defined by a catalog. Adding an item is always the first step you want to do, then followed by creating a BOM.

REGISTER FOR FREE to check out how OpenBOM can help you and start a 14-day trial today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.