In today’s dynamic business landscape, the seamless exchange of product data between manufacturers and their suppliers has become a cornerstone of successful supply chain management. The introduction of streamlined data handover processes not only enhances operational efficiency but also significantly impacts product quality and customer satisfaction.

Efficient data handover processes contribute to the smooth flow of information across the supply chain, minimizing delays, reducing errors, and optimizing resource utilization. By providing suppliers with comprehensive and accurate product data, manufacturers can foster greater collaboration and alignment, leading to improved production planning and inventory management.

In addition, streamlined data handover processes empower companies to respond swiftly to market demands and changing consumer preferences. With access to real-time insights and up-to-date information, suppliers can adapt their manufacturing processes accordingly, enabling businesses to stay agile and competitive in today’s fast-paced marketplace.

Ultimately, the success of any supply chain hinges on effective communication and collaboration between stakeholders. By prioritizing the efficient transfer of product data to suppliers, organizations can unlock new opportunities for innovation, reduce time-to-market, and elevate the overall quality of their products and services.

In this blog, we will go over the best practices for successfully handing over product data to suppliers.

Understanding Supplier Requirements

One of the fundamental pillars of effective data handover to suppliers is understanding your supplier’s unique data needs and preferences. Each supplier operates within its own set of processes, systems, and requirements, making it essential for businesses to engage in proactive communication and collaboration to ensure a smooth exchange of product data.

Understanding your supplier’s specific data requirements is paramount to facilitating a seamless handover process. By gaining insights into the types of data they need, the formats they prefer, and the frequency of updates required, businesses can tailor their data management strategies to meet supplier expectations effectively.

Moreover, clear and open communication with suppliers is key to clarifying requirements and aligning expectations. Establishing channels for dialogue allows both parties to discuss data transfer protocols, address any potential challenges or constraints, and establish mutual understanding regarding timelines and deliverables.

Through collaborative efforts, businesses can gain valuable insights into their supplier’s operational capabilities and constraints, enabling them to make informed decisions about data preparation and transfer methods. Additionally, fostering a culture of collaboration fosters trust and strengthens relationships between businesses and their suppliers, paving the way for long-term partnerships built on mutual respect and shared objectives.

In summary, understanding your supplier’s specific data requirements and fostering open communication and collaboration are essential prerequisites for successful data handover processes. By prioritizing these elements, businesses can streamline the exchange of product data, mitigate risks, and unlock new opportunities for innovation and growth within their supply chains.

Preparing Your Product Data

As manufacturers collaborate with suppliers, particularly in regions like China, preparing product data becomes crucial.

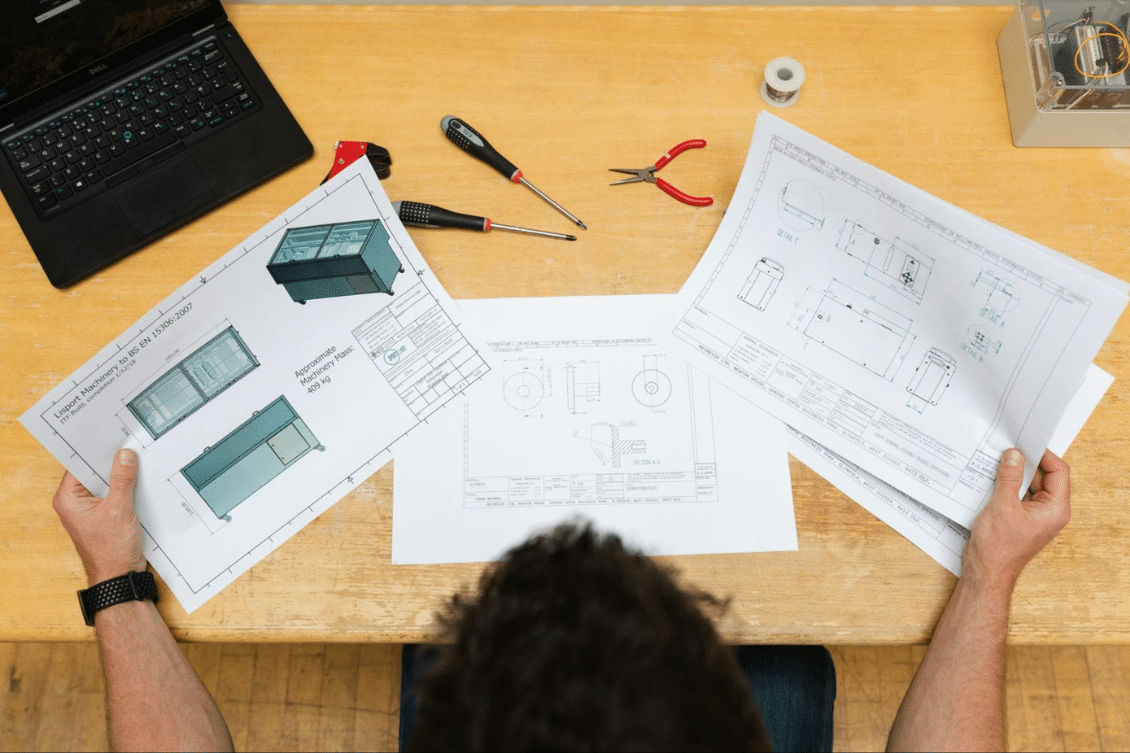

What you will share with your supplier is often shared during the Request for Quotation (RFQ) process. When you prepare to send over your product data to your supplier, you need to keep in mind that your supplier is blind to this project. While just dumping data via emails might work, it’s not the most effective solution. Think about the best ways to introduce your product to a supplier and prepare all of the data that’s necessary.

The necessary product data can include:

- Bill of Materials (BOM)

- Design Files

- Quality Standard

- Assembly Steps

Selecting Data Transfer Methods and Tools

When it comes to sharing product data with suppliers, selecting the right data transfer methods and tools is crucial for ensuring smooth communication and collaboration. Manufacturers can often use spreadsheets because of their familiar look. However, there are better methods as spreadsheets were not created to share product data.

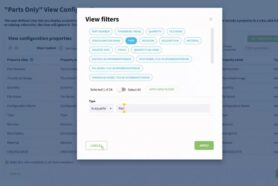

When evaluating data transfer methods, consider factors such as security, scalability, and compatibility with supplier systems. In addition, creating a single source of truth for all product data is important. You want to make sure that not just your entire team is working on the same product data but all suppliers, including alternative suppliers. You never know when you need to navigate your supply chain quickly.

Selecting the appropriate data transfer tools and technologies should align with business requirements and budget considerations. Look for solutions that offer a balance of functionality, reliability, and affordability. Consider factors such as ease of use, customer support, and integration capabilities when evaluating potential tools. If you are searching, you can check out our product tour page.

Establishing Clear Communication Channels

Clear and effective communication with suppliers is paramount throughout the data handover process. Here’s how to ensure open and transparent communication channels:

Stress the Importance of Open Communication:

Emphasize the significance of open and transparent communication with suppliers at every stage of the data handover process. Clear communication fosters trust, enhances collaboration, and mitigates the risk of misunderstandings or errors. Depending on where your supplier is located you might need to use some different tools, such as WeChat, if they don’t use WhatsApp, slack, and some other communication tools.

Discuss Strategies for Clear Communication Channels:

Define strategies for establishing clear communication channels with suppliers. This may include regular meetings, email updates, or dedicated communication platforms. Clearly define roles and responsibilities for both parties involved in the data exchange process to minimize confusion and ensure accountability.

Emphasize Regular Communication and Feedback:

Highlight the value of regular communication and feedback loops throughout the data handover process. Encourage open dialogue between your team and suppliers to address any issues, concerns, or questions that may arise promptly. Establishing feedback mechanisms allows for continuous improvement and refinement of data handover workflows. In other words, there is nothing wrong with overcommunicating certain things.

Conclusion

The successful handover of product data to suppliers is a critical aspect of ensuring operational efficiency, product quality, and customer satisfaction. From understanding supplier requirements to selecting suitable data transfer methods and establishing clear communication channels, each step plays a vital role in optimizing collaboration and streamlining operations across the supply chain. By prioritizing transparency, accuracy, and proactive communication, businesses can forge stronger partnerships with their suppliers, driving innovation, and delivering exceptional value to customers.

OpenBOM can offer significant value when it comes to sharing product data with suppliers. OpenBOM provides a user-friendly platform designed to simplify data management, streamline collaboration, and enhance communication throughout the data handover process. With features such as centralized data storage, real-time updates, and customizable workflows, OpenBOM empowers businesses to effectively manage product data and facilitate seamless collaboration with suppliers.

By: Jared Haw

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.