My attention was caught by the Dragon Innovation article BOM 101. Dragon Innovation is a great company, part of Avnet and providing consulting to hardware startups on how to set up manufacturing in China. In the article, they told about BOM tools and this is the place where I think they got it a bit wrong — a typical tool for BOM is a spreadsheet, people call it a part list, but in fact, it is a BOM. Here is the passage:

A typical tool for creating a BOM is a spreadsheet. Traditionally this has meant Excel, more recently — Google sheets, Office 365, or other web based spreadsheet systems. The advantage of real time web based systems (not files saved to a shared folder) is you can be certain everyone is looking at the same version of the document. This becomes your one source of truth. Sharing traditional files can result in some people having old files and wasting time working with outdated information, which has been and continues to be a challenge.

There are numerous BOM templates available online — including one from Dragon innovation using Google sheets — that you can easily download and customize to work for your project. There is also purpose built BOM software. I have never been involved in a project where the features were worth the extra cost and setup, but as teams grow and assembly complexity increases, the special features of these systems become more useful and worth the cost.

It made me think about why a spreadsheet is a bad single source of tools for BOM. Here are my top 3 reasons:

- No structure

- No reference instance relationships

- No visuals

Structure

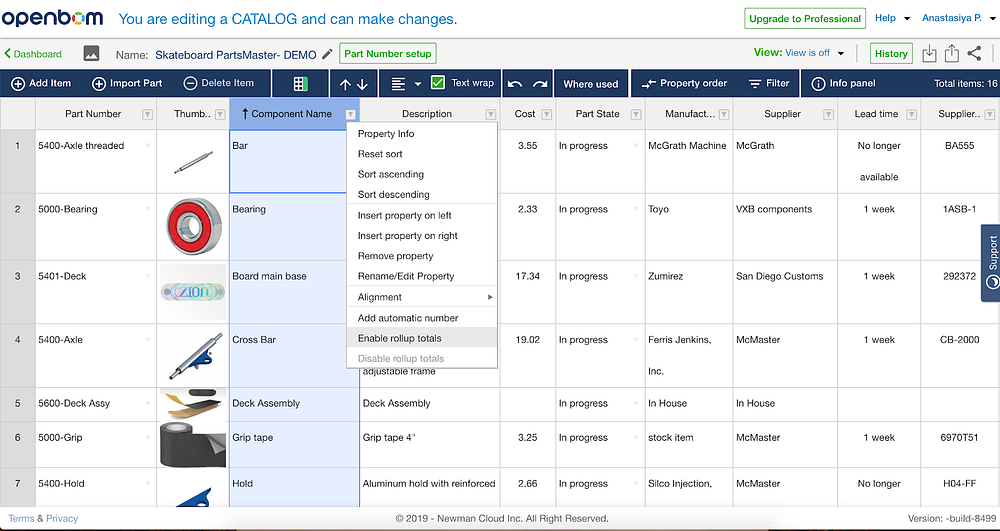

The fundamental element of BOM is product structure. Here are some examples. Engineers think pretty much hierarchical (assemblies, sub-assemblies, components). Other people involved in planning and manufacturing need to restructure it to provide planning list classified by components type or source type, etc. Rollups should be done and presented in descending order of cost.

A spreadsheet is a bad tool to manage structures and relationships.

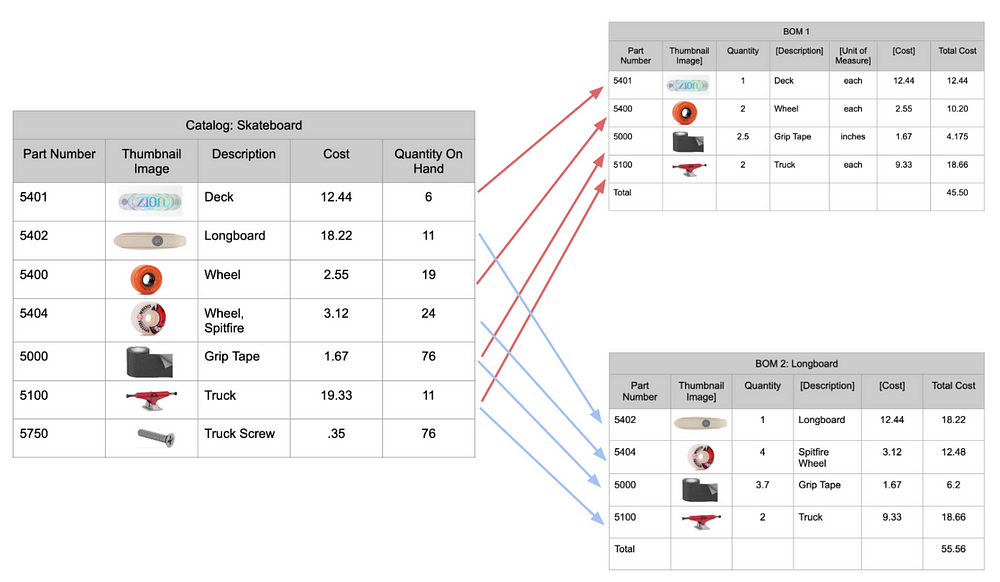

Reference instance relationships

The second fundamental element of BOM model is the ability to manage relationships between a reference (eg. a screw) and its instance in your product (you might have 10 screws in different assemblies). Without such a model, you’re going to have a lot of redundant elements of data in your spreadsheets or… alternatively, you will have to flatten your structure manually and it will be disconnected from “truth” — the product structure.

Spreadsheets are not able to manage the reference instance model.

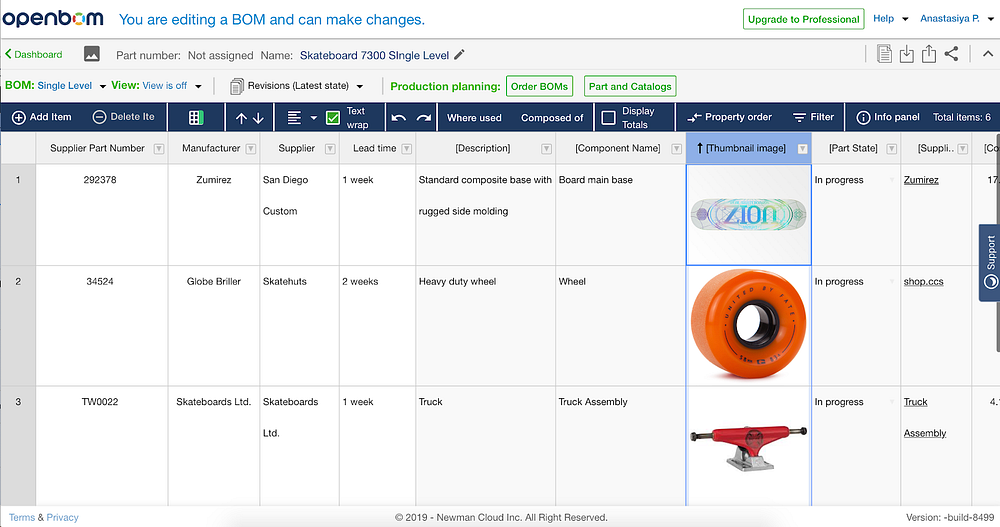

Visual

The picture speaks for a thousand words. If you see a visual representation of a part, it can help you eliminate mistakes and focus on the right stuff. You can embed a picture into a spreadsheet, but it is too much work. Also, 80% of these pictures are coming from CAD software, therefore it’s impossible to make it manual.

Once you use visual BOM, you won’t be able to come back to a simple list of numbers.

Cost of typical BOM Tools

There is one thing I agree with James Berg. Most of BOM tools on the market are too expensive and require a costly setup — PDM, PLM, ERP tools.

However, I have good news — OpenBOM is different. With free subscription and professional subscription starting at 10$, you can automatically create BOMs from CAD tools, create rollups and get automatic flattened BOM with quantities. OpenBOM is as flexible as a spreadsheet but eliminates all disadvantages of spreadsheets I mentioned above.

Feel free to review our pricing plans.

Conclusion

BOM looks like a simple list but in reality, it is not. It has a structure, references, instances and requires processing of data that can be hardly done in a spreadsheet.

OpenBOM is a new generation tool for BOM management that can help you improve the way you control BOM and use it for planning. Check OpenBOM production planning and purchasing support — you can get purchase orders generated automatically.

Register for free to OpenBOM and leave the spreadsheet mess behind.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.