Spreadsheets are everywhere. Every engineer, buyer, or project manager has their own system—color-coded tabs, clever formulas, and “just one more” version saved on the desktop. Individually, it works. It feels fast, flexible, and under control.

But zoom out, and a different picture emerges: the organization is stuck. Teams are siloed, data is duplicated, and processes are built on fragile exports, email chains, and version mismatches. What seems productive at the individual level is holding the entire operation back—costing time, accuracy, and valuable opportunities.

Why Spreadsheets Still Dominate (and Why That’s a Problem)

The PLM industry has spent decades trying to eliminate spreadsheets, but despite all efforts, Excel still thrives in 2025. The reason? Spreadsheets are deceptively powerful. Engineers love them because they’re quick, familiar, and give a sense of control.

But there’s more to the story. Over time, spreadsheets became deeply embedded in business processes—from managing BOMs to tracking supplier lead times. Replacing them isn’t just technical—it’s organizational and cultural.

One real-world example makes this clear.

OpenBOM customer, Vartech Systems developing rugged computers and monitors. VarTech Systems’ rugged computers and monitors are entirely engineered, manufactured, and assembled in their US-based facility in North Carolina. A leader in performance and reliability, their systems and components are designed specifically for demanding, diverse environments and used by industrial leaders worldwide; NASA, General Motors, Caterpillar, and Disney, to name a few. OpenBOM is proud to be an approved technology provider to Vartech Systems since 2020.

“What we love most about OpenBOM”, Max says, “is the ability to change one thing in our BOM and it shows up everywhere the item or component is used!”

“That may seem a simple claim, but the ability to know that what we build and deliver to our customers has current pricing and components is very important to our business.”

“OpenBOM easily saves us 2 hours a day in engineering time. I remember we caught a $1000 mistake the first month we had OpenBOM. Our Excel had not been updated. OpenBOM literally paid for itself that month.”

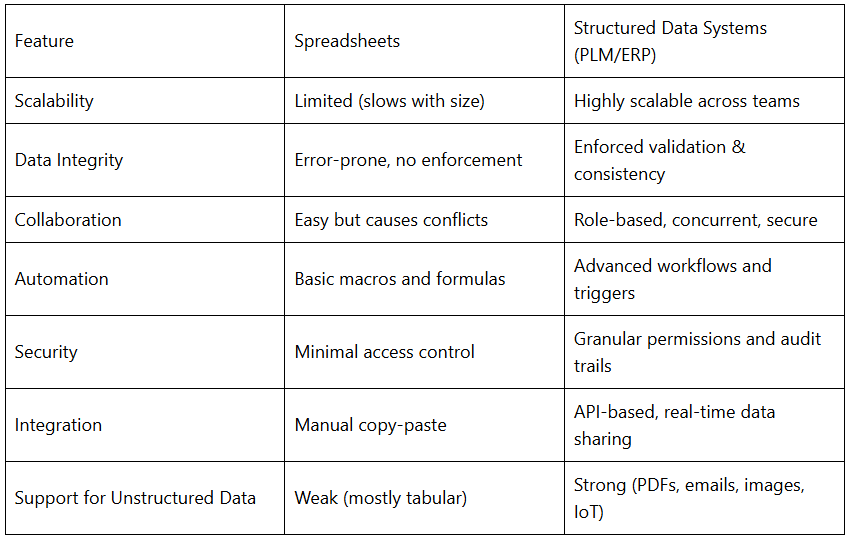

The Hidden Risks of Spreadsheet Dependency

While spreadsheets offer speed and flexibility, they come with serious downsides. Research from the University of Hawaii revealed that over 88% of spreadsheets contain errors. In manufacturing, these can translate into misordered parts, missed deadlines, and broken processes. Deloitte’s data reinforces this, showing that poor data management leads to over 30% operational inefficiency in many manufacturers. These aren’t small inefficiencies—they’re massive drains on productivity, customer satisfaction, and margins.

In addition, spreadsheets fall short when it comes to security, collaboration, and automation. With no enforced validation or role-based access, a simple mistake or unauthorized change can have widespread impact—especially when teams rely on shared folders or email attachments for daily operations.

📋 Spreadsheets vs. Structured Data: A Clear Comparison

This contrast makes one thing clear: the path to digital transformation doesn’t run through spreadsheets.

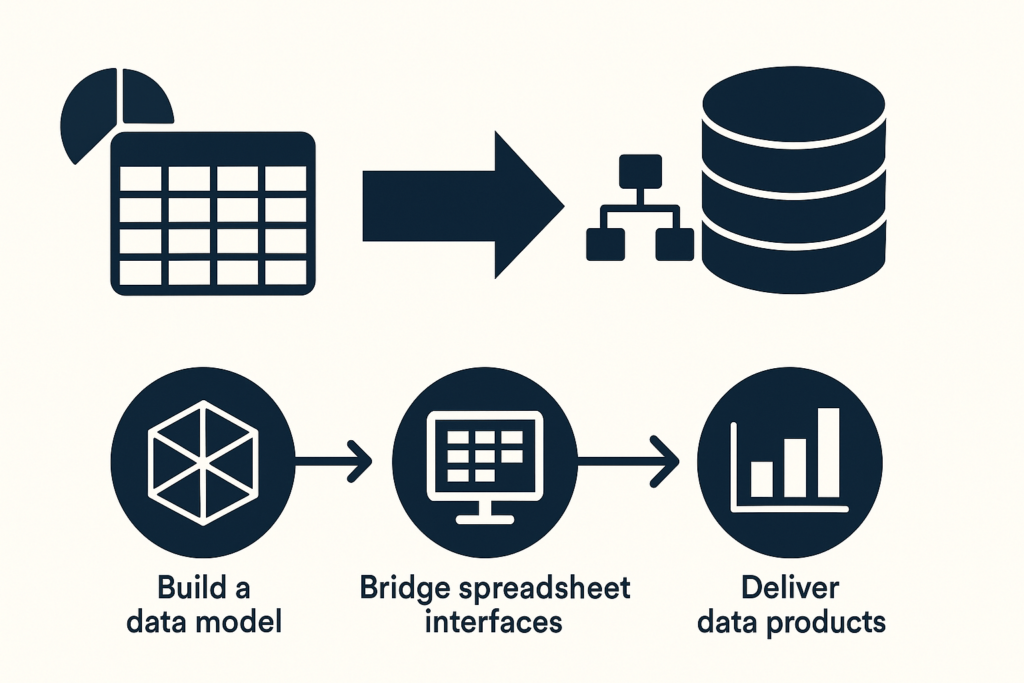

What’s the Way Forward? A 3-Point Strategy

Rather than declaring war on spreadsheets, manufacturers should adopt a more strategic path forward—one that respects existing behaviors while guiding organizations to something better.

Build a robust and flexible core data model

The first step is building a robust and flexible data model that reflects how your company works. You don’t need to model everything on day one. Start small—perhaps with your BOMs or part master data—and gradually evolve the system. The goal is to create a central, reusable foundation for structured data that grows over time.

Enable interfaces that support a familiar spreadsheet workflow

The second step is enabling interfaces that support familiar spreadsheet workflows. Many users won’t embrace new systems unless they feel natural. That’s why it’s critical to provide table-like experiences, easy imports and exports, and even intelligent agents that can read a spreadsheet and automatically update structured data in the background. In this transition phase, spreadsheets become a gateway—not a dead end.

Deliver Data Products

Finally, once the foundation is in place, begin delivering business value through what we call data products. These could be automated cost reports, supplier dashboards, or reuse analytics. Unlike spreadsheets, these outputs are always current, collaborative, and scalable. When your organization sees the insights and decisions that structured data can deliver, the incentive to move beyond Excel becomes self-evident.

Tackling Cultural Resistance

Technology alone won’t solve this. People resist change for many reasons—fear of complexity, attachment to old habits, or skepticism that new tools will actually work. The key is to lead with empathy. Involve users in the design process. Start with small, high-impact areas where errors are common. Show quick wins. And provide training that focuses on outcomes, not just features. When people feel heard and supported, they’re far more likely to adopt new practices.

Build for the Future

The benefits of a structured data foundation go far beyond fixing today’s inefficiencies. With the right model in place, manufacturers unlock capabilities like AI-driven analytics, predictive maintenance, closed-loop quality, and digital twins. What begins as a way to avoid spreadsheet errors quickly becomes the engine of competitive advantage.

Conclusion: A Call to Action

The way out of Excel is not a one-time rip-and-replace—it’s a process. Start by auditing your current spreadsheet usage. Identify the most fragile, high-risk processes. Begin building a structured data foundation to support them. Introduce smart interfaces to bridge old habits. And finally, use that foundation to deliver data-driven value that Excel alone can’t provide.

The future of manufacturing belongs to those who move beyond spreadsheets—one process at a time.

REGISTER FOR FREE to get access to OpenBOM and check how it can help

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.