On the surface, Bill of Materials (BOM) is simple. This is the first thing that comes to mind when you think about Bill of Materials as a list of parts. In fact, BOMs are not simple. Here are just a few ideas about what can make BOM management a very complex task leading to frustration, debates about how to own and manage it and variety of options involved.

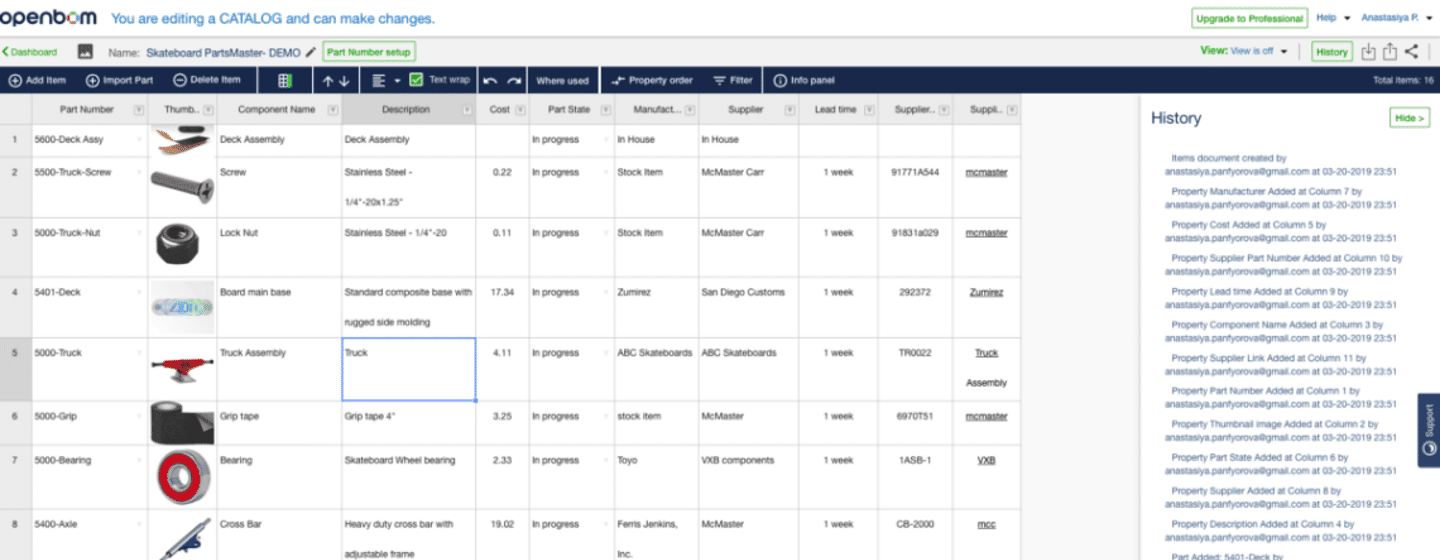

Speaking to many new and existing users and customers of OpenBOM made me think of the need to provide information about the way OpenBOM is organized. Which means to provide more information about OpenBOM’s conceptual model, its flexibility, and options.

I like using simple models to demonstrate how OpenBOM works. One of my favorites is a model of a skateboard.

The model above is obviously simplified.

However, I’d like to bring your attention to two groups of information. The first one is the lower part with a wheel, a board, an axle, and screws. The second group is the actual skateboard with one board, 2 axle assemblies, 4 wheels, and a bunch of screws.

The first group contains abstract parts (or components). This is something that OpenBOM catalogs are used for. You may think of OpenBOM catalogs as a distributed database of all parts, assemblies, and everything else you need for your products (eg. materials, purchased assemblies or even labor needed to assemble products).

The second group contains real products you design or manufacture. Think of it as a specific thing. Usually represented and uniquely identified by Part Number. This is what OpenBOM’s Bill of Materials used for. Depending on the situation, it can be an engineering BOM (EBOM), Manufacturing BOM (MBOM) or any other (support and maintenance, or supply chain).

Conclusion

BOMs and Catalogs are fundamental elements of OpenBOM Reference-Instance model. A typical use of OpenBOM is to create catalogs with parts and then start creating Bill of Materials using parts and assemblies from catalogs.

In the next article, we will talk about creating a catalog and then building a BOM. Stay tuned!

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.