A few years ago, I was talking to one manufacturing company. They developed great products, but struggle with execution and manufacturing. I asked them – how do you manage Bill of Materials? The answer was shocking… They told me “we don’t”….. 12!@#!@(@(#!@# – that was my answer. How come? What do you do? The person I was talking to told me that they don’t need BOMs. They just create “lists”. Many lists… In many Excels. List for assembly, list for cost, list for purchasing… Everyone holds his (or her) list and trying to achieve the goal – to make a product and to send it to a customer who bought it.

And this is how everything is screwed up. It was a small company. They had a dozen people when I talked to them. And they struggled between silos of information (aka “lists”) and every single person was getting wrong data.

I told you this short story to explain why basics are important. And the basics of BOM management are in two main things:

- BOM is a list that everyone will be using to make a product.

- Share it with the team is absolutely important.

Here are some basic definitions:

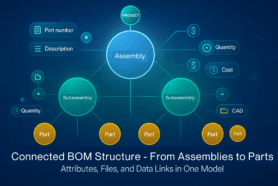

- A Bill of Materials is a list of the raw materials, sub-assemblies, intermediate assemblies, sub-components, parts, and the quantities of each needed to manufacture an end product.

- A Part Number is an unambiguous identifier of a particular part design. Its purpose is to simplify reference to that part.

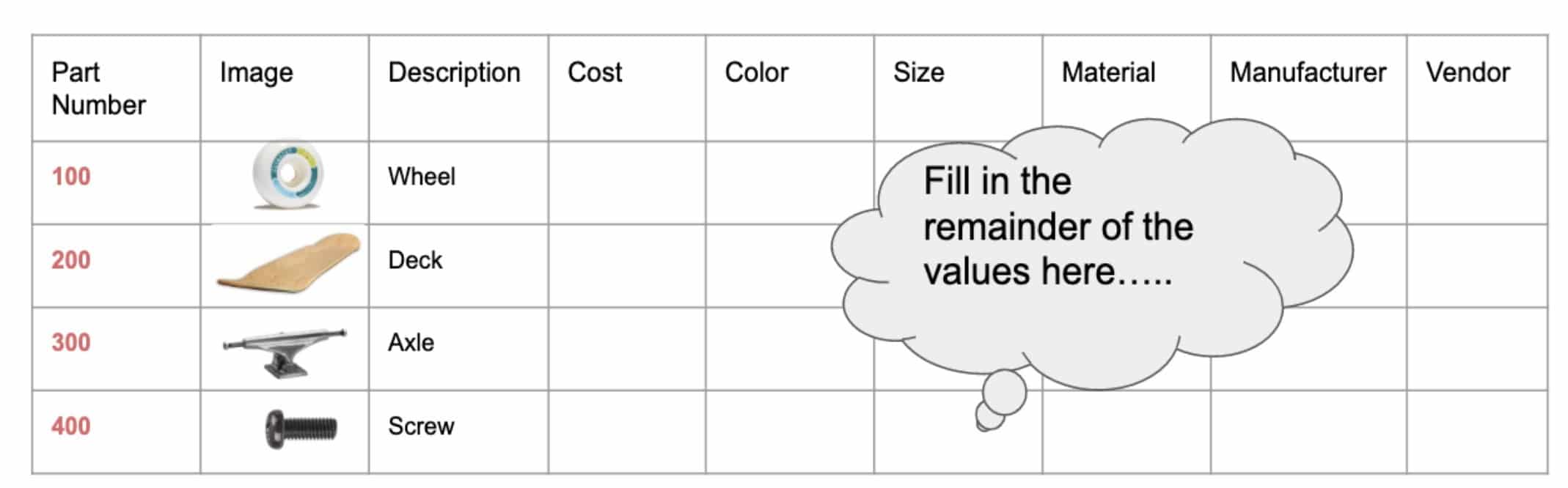

- A Part (Often called an Item) is generally defined as a thing in your BOM.

- A Property is the piece of data you wish to store for a particular Item, the column header (ex. Cost or Description)

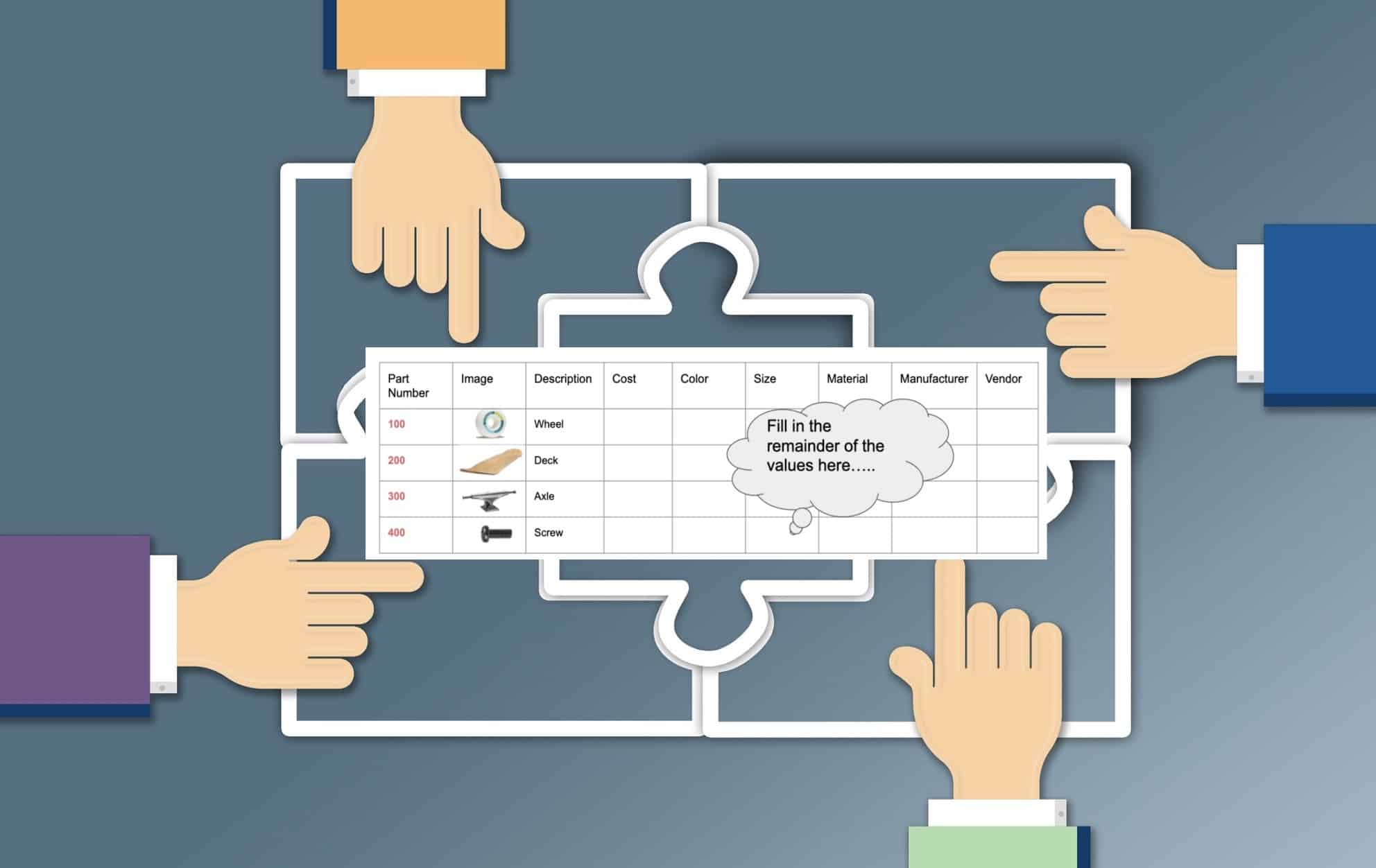

The information in the BOM that might look like this one is coming from many people.

And to fill all this data, you need your team to contribute, which means share and collaborate.

Below is the slide deck from the BOM management educational webinar that gives you more information about how to plan your BOM information and how to manage it.

And this is a video recording from the webinar.

Conclusion.

BOM is the lifeblood of product development and manufacturing activity. Even a small team needs to have a single record of the components, structure, quantity, dependencies and enrich it with the information from who it will be acquired (purchased or made) and how to combine (assembly) it together.

Register to FREE OpenBOM User Subscription to make the first steps in your product development transformation.

Best, Oleg @ openbom dot com.

Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Image by Gerd Altmann from Pixabay

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.