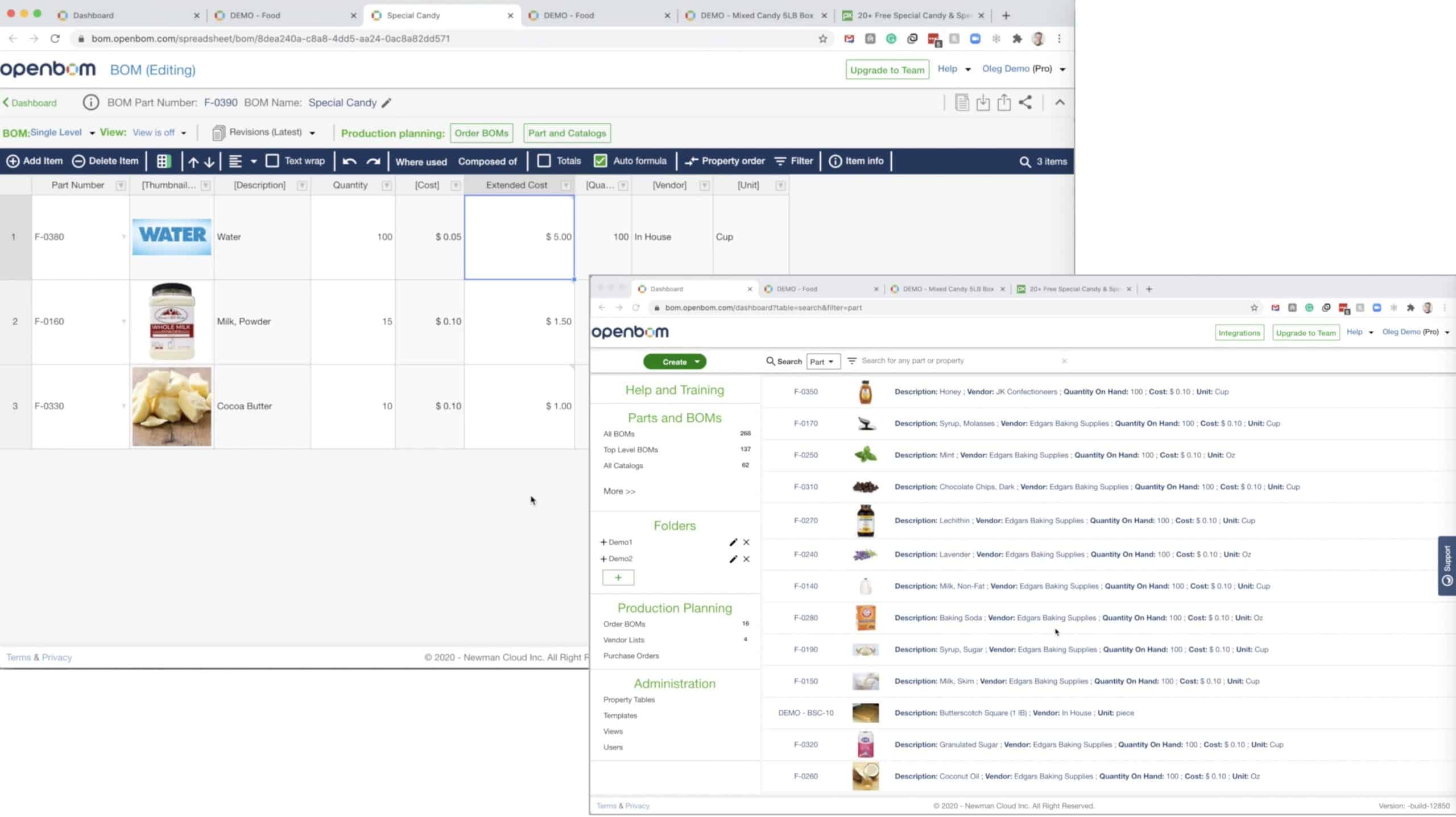

In my blog today. I want to talk about the basics of how to manage information in OpenBOM. And basics of OpenBOM is about how to create a product BOM, to manage parts, and add them to the BOM. Remember, simplicity is of of the most important elements of OpenBOM. We know how important to stay simple when you manage complex data. This video will give you a set of simple steps to manage data in OpenBOM. I will use existing items already defined in the OpenBOM demo database. In my next videos, I will talk more about how to create catalogs and manage structures, but for today, we just stay with the simple – Product, its BOM, and parts.

Here is a simple sequence of steps.

1- Navigate to the Parts dashboard and search for parts you have.

2- Once you found what you need, open the catalog with these parts

3- Check the definition of parts in the catalog

4- Add a new item to the catalog for a new product you’re going to create

5- Navigate to the BOM for the created part (OpenBOM will create a one for you).

6- Open a new created BOM (hint – it will be empty)

7- Check the BOM is using the correct catalog(s) for items. Keep in mind you can use as many catalogs for items you need.

8- Add items (Parts) to a new BOM.

Check this video that illustrates these steps.

Conclusion

In a simple 8 steps and a few minutes, you learned how OpenBOM allows you to create a new product, to create a BOM, and add items to this BOM. I hope you enjoy the simplicity of these steps. OpenBOM is completely flexible and you can define any parameters for items in the catalog(s) as well as for instance attributes (eg. Quantity, Reference Designator, etc.) in BOMs. In my next videos, I will cover the creation of multi-level BOMs and the management of catalogs. You can also learn about the Product Lifecycle Management system that is commonly known as a PLM. It is a crucial aspect to focus your attention on. It consists of different components such as document management, workflow, data management, Bill of Material management, and more. Stay tuned.

Check what OpenBOM can do for you – REGISTER FREE

Best, Oleg @ openbom dot com.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website. Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.