The design and creation of a product begin with a bill of materials (BOM). The BOM outlines the raw materials and components that are needed to manufacture the product. In order to ensure that the product is created correctly and efficiently, it is important to carefully plan and compile the BOM. However, nothing can be done until the materials and components are purchased and delivered to the shop floor. OpenBOM supports you by creating an integrated design for the purchase process and a solution to organize RFQ and PO processing based on the Bill of Materials information.

Purchasing and Materials Packaging

Packaging of components for purchases can be very tricky. Usually, engineers create a Bill of Materials (BOM) using sizes and quantities aligned with engineering and design. However, for your procurement team, these design units of measure (UOM) may not be very helpful. For example, BOM will be defining the number of screws and the length of the pipe. However, this UOM is only used for the BOM. When it comes to the calculations, a procurement department is looking for a packaging size and not for engineering sizes.

This is when things start to get very complex. An engineering BOM has one set of UOM, purchasing is demanding a different set. Recalculations are not a very complex function, but not all tools can support it in an easy fashion. This is how often the procurement team needs to request to export everything to Excel to calculate, which technically creates an even bigger problem. It works one time, but when you need to make updates, you will be st

In my blog today, I will give you an example of how to extend BOM in OpenBOM with additional information that can later help you to perform packaging sizes calculations in OpenBOM Orders.

Catalogs and BOMs

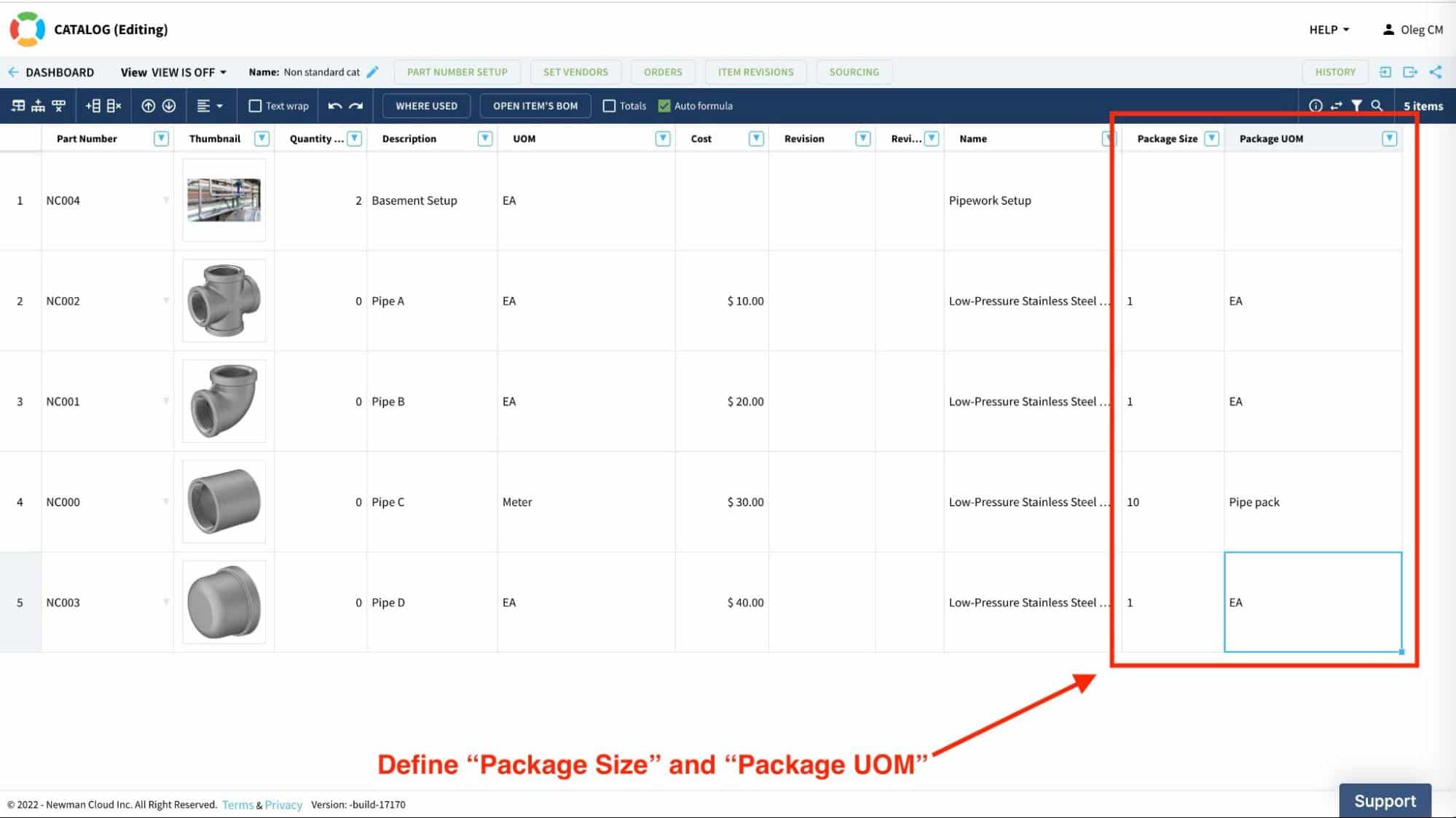

The foundation of any information in OpenBOM is cataloging where you store information about the item. In case of order, in addition to regular item information, we will add information about packaging size and UOM (unit of measurement).

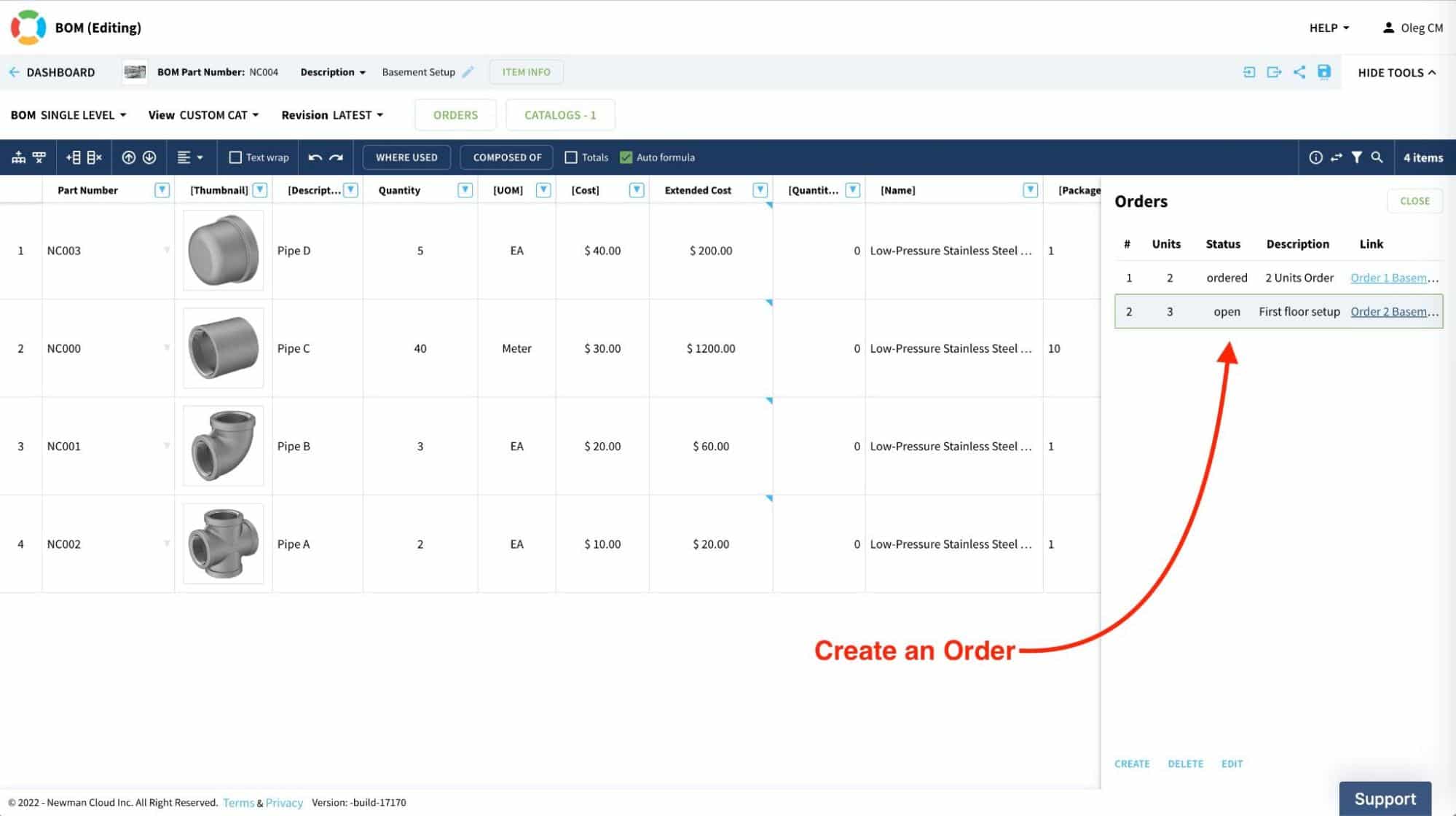

Once the data is added you can create an order using OpenBOM order command.

Orders and Calculations

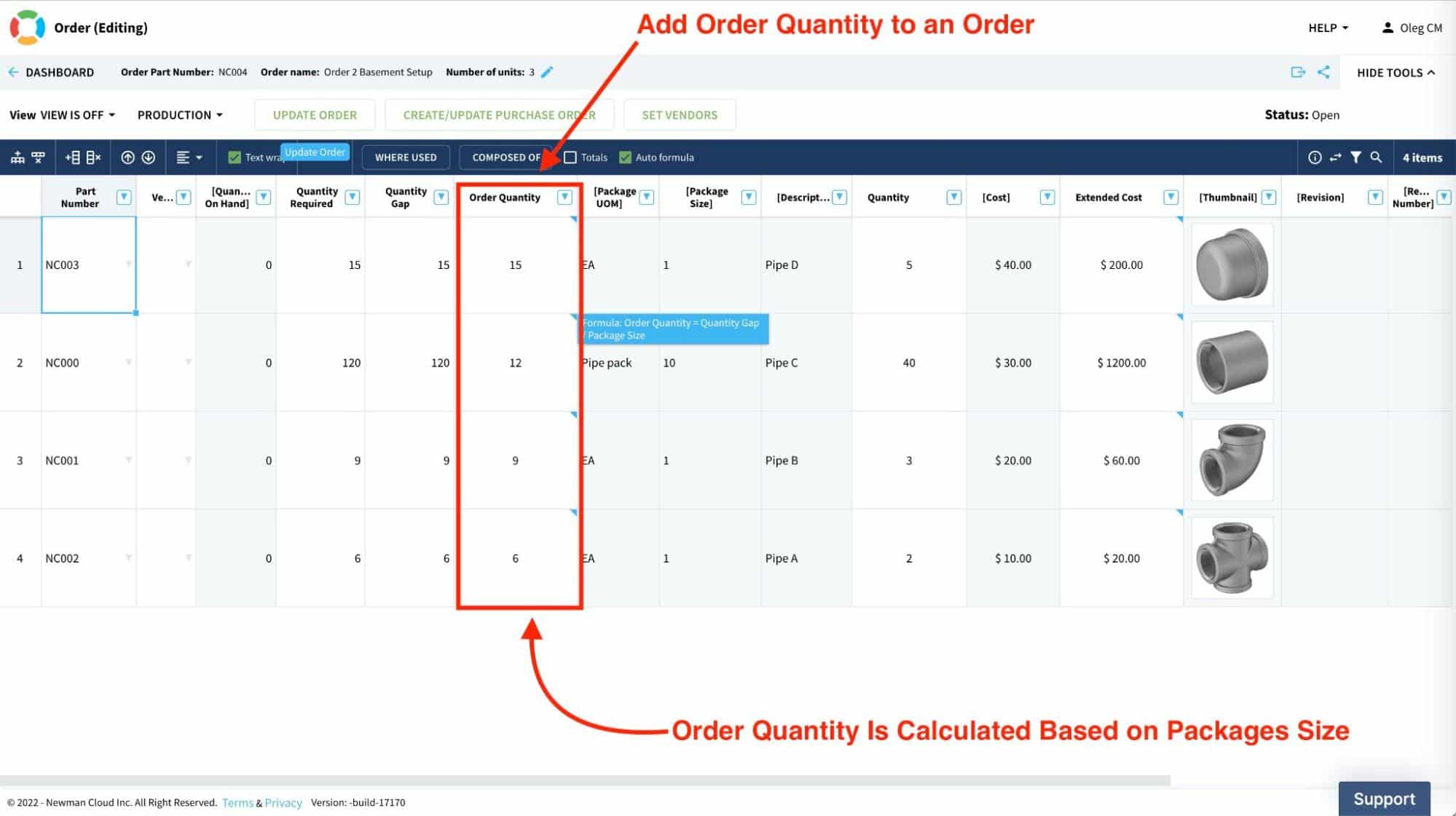

After an Order is created, you need to add an Order Quantity property to an order and define a formula to calculate it based on the Quantity Required and Package size.

Conclusion

Management of purchasing process can be a complex task when it is done using Excel spreadsheets and manual data inputs. The purchasing team is using Bill of Materials as input and then calculates the number of boxes, packs, and other material packaging quantities. Updates are painful and keeping in sync with planning and BOM changes is even harder.

OpenBOM gives you a seamless data handover between BOM and Order, organizing data sync and supporting formulas to automatically calculate the needed number of boxes, packs, and other related materials, which makes the purchasing process a breeze compared to manual calculations.

REGISTER FOR FREE to try OpenBOM today and check out how OpenBOM can help you today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.