Bill of Materials in Excel is a thing of the past. But for many companies, it is still a long way. If you can make it, you will secure the space in the digital manufacturing future and won’t stay behind.

If you’ve been following my blog at all, you’ll know by now that a bill of materials (BOM) is a recipe for your product.

It contains all items, materials, components, assemblies, and everything else needed to create a product. It sounds simple, but because of the high diversity of manufacturing processes, industries, supply chain, and business relationships, a Bill of Materials is not a simple entity.

The bill of materials explains what, where, how to buy, build, acquire or prepare every item that needs to be included in the product. The bill of materials is needed in every manufacturing process, but the way it’s created, managed, and maintained is changing like everything else in our lives these days.

Back In The Days

The old way of doing things consisted of creating a Bill of Materials in an Excel spreadsheet.

When the only thing you have is a hammer, everything around you is a nail. If a table is your way of managing a BOM, then I’m sorry to say, your processes will be very limited and cost you a pretty penny.

So before making the grave mistake of managing your BOM’s in a spreadsheet, I recommend you do some homework and find a better way to manage it. Take some time and check out previous blogs I have written on features that OpenBOM provides customers or better yet try out our 14 Day Trial!

Part Numbering Schema

Before you start developing your BOM one thing should be on your mind…Part Numbers. The earlier you make the right decision about part numbering the smoother things will go for you. Getting this right, in the beginning, can save you a ton of money and time.

Adding a Part Number might sound like a cheap thing to do, but it ties together revisions, change process, and many other things. Every new Part Number, as well as Change Process (ECO), can cost a small fortune if you calculate the entire time your company will spend on this.

Item Records and Multi-Disciplinary Information

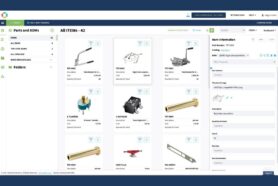

Everything to do with BOMs focuses on items. An Item is a universal representation of anything you need to accomplish – it is a data foundation for your process because it will connect all the pieces together.

Managing Items is absolutely important. Collecting all item information in your company and pulling it together with multiple sources (Excels, legacy databases, drawing sheets) will make a good first step in organizing a single source of truth in your company.

Start by defining what parameters to manage for each item (eg. Part Number, Description, Cost, Unit Of Measure, Revision, Manufacturer, Supplier, etc.) is a good start.

Digital World – Move From Syncing to Sharing

While email was a great way to move from a paper trail to some sort of digital process, it is a limiting factor in the way it organizes your information. By sending data in Excel via email or PDF file, you can very soon lose track of your process and data., revision, file, change or anything else. So, placing the data in the middle and sharing data in real-time is the modern way to work with data. Check for systems that can help you do so by connecting your engineers, contractors, and suppliers together.

BOM Changes, Revisions, Views

Companies are relying on digital records to be more accurate and eliminate mistakes. Each time you re-enter data and change it manually, you have a chance of making a mistake. If the process of copy/ export/change is part of the process of work between engineers in the company as well as between contractors and suppliers, it eventually will come to collapse.

To prevent it, the data needs to be organized, changes need to be managed and revisions preserved to give you the data traceability. If you don’t do it – it is just a matter of time before you lose control.

There are two aspects of data control – (1) changes/revisions; (2) access control. You need to think about how to track every change and identify the level of data that needs to be shared (eg. Revision and not work-in-progress data).

Second thing is to control who has access to which information. Organizing views can be a good idea and used as a lens to access the data. Then every person based in that role will have the right access.

Conclusion

The time when BOM was a simple table in Excel or drawing sheet is gone. Companies that still operate this way are basically creating a time bomb for them in the future. The digital transformation is raising many questions, but the main focus is on how to transfer old fashion paper sheet process into a new digital form. A proper organization of product information from the early beginning will allow you to save tons of money in the future.

Check how OpenBOM can help. Create a FREE OpenBOM Account here.

Contact us, we will be happy to help.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.