In my previous blog, I provided a quick introduction to OpenBOM’s formulas and demonstrated how you can use formulas to rollup any property value in a BOM (eg. Cost, Mass, Volume, etc.) If you missed this article, check it out here – Jumpstart your efforts with OpenBOM cost rollup.

Use Case

Today, we are going to talk about conditional formulas, which is another powerful mechanism to manage costs for your products using OpenBOM.

In a nutshell, the use case for conditional rollup is to be able to control the rollup and prevent a rollup function in OpenBOM from going down from a specific level.

Model

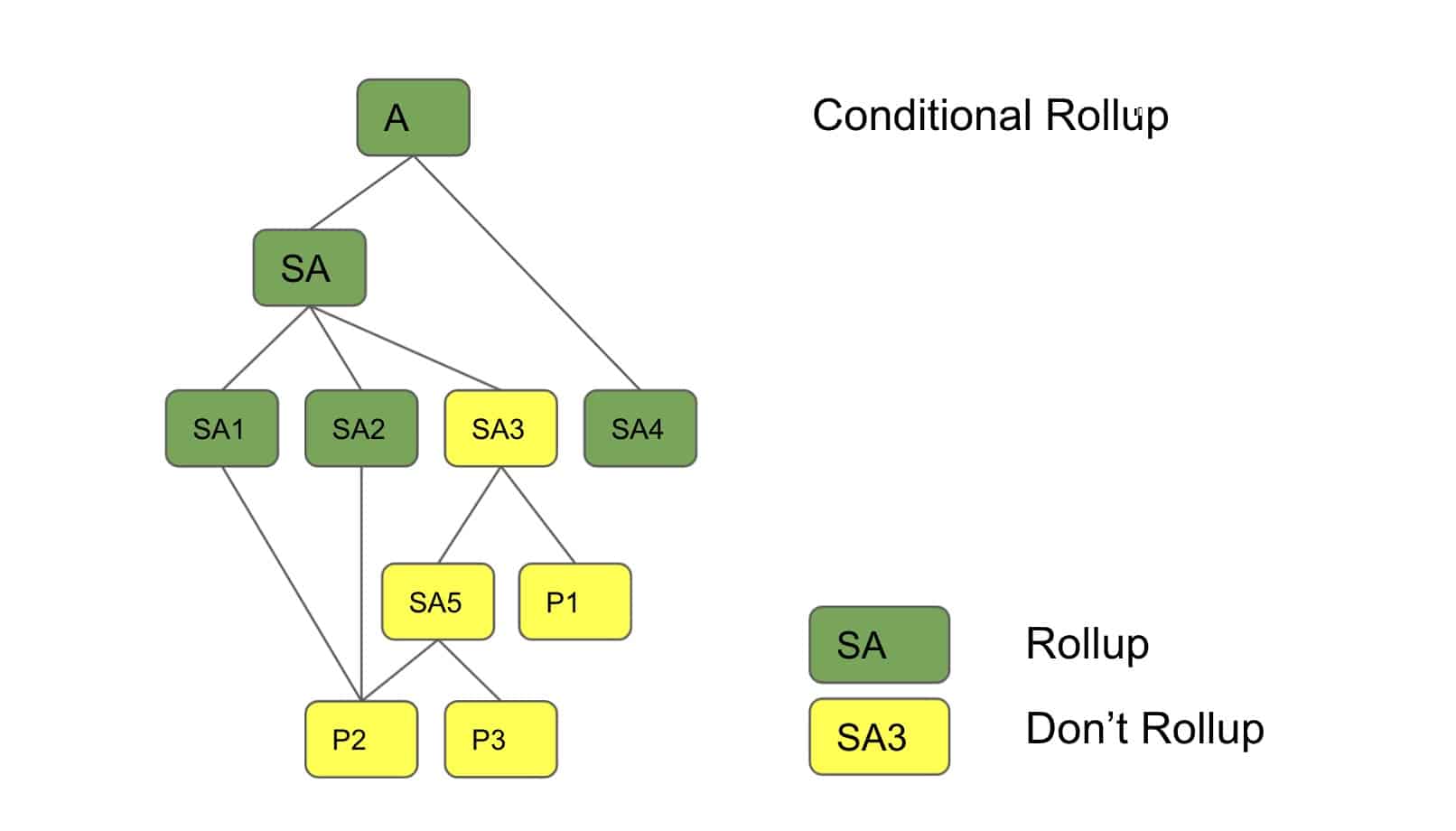

As you can see in the image below, I have an assembly structure and I’d like to prevent SA3 costs from being rolled up and calculated from SA5, P1, P2, and P3. Instead, I’d like SA3 cost to be defined in the catalog as a purchased price.

To make it happen, you need to define a property in the catalog that will define a condition for the rollup. Once this property and value are defined, you can use it as a condition.

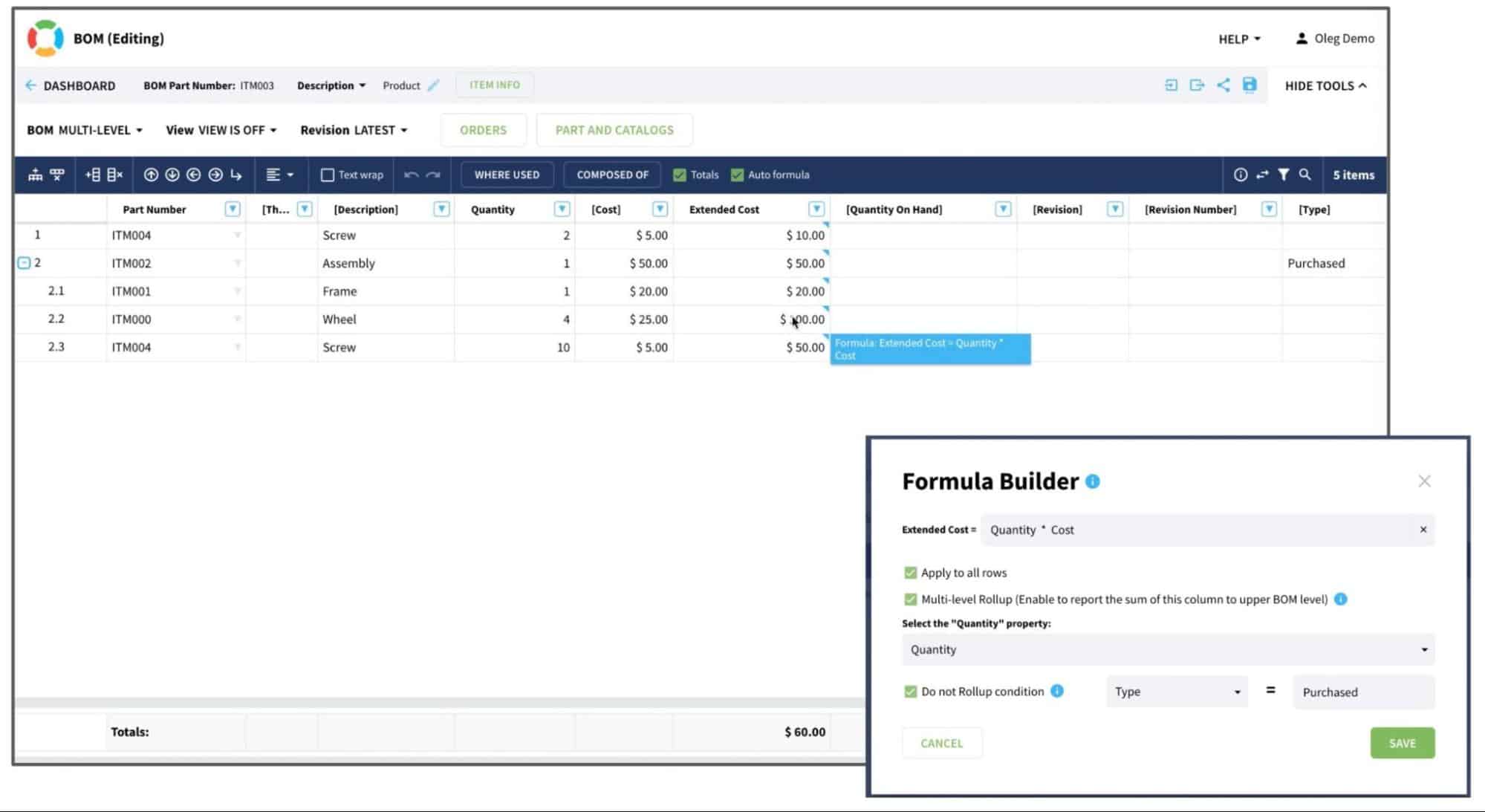

In my example below, I used the property Type and the value Purchased as a condition to stop the rollup.Video Example

In the following video, I show you how you can define the conditional rollup and switch the cost of the BOM cost calculation from one option to another.

Customer Example

OpenBOM formulas and calculations are a powerful tool that allows you to define various conditions about how cost (and other values) can be calculated based on the different conditions. It helps you run a flexible calculation model to manage cost and many other characteristics of your design.

One of my favorite use cases is new product development. In the following OpenBOM user story a Fortune 500 consumer electronics manufacturer is using OpenBOM to improve their collaboration in NPD (New product development) processes. By replacing messy Excels, engineers and managers cut their time spent on managing BOMs from 5 hours weekly to only 10 minutes.

“The existing legacy PLM environment is too complex and too costly, cannot deliver an easy model to collaborate, and fails to provide an agile environment for production planning, which is typically handled by a super sophisticated corporate ERP system. “

“We had multiple places and Excel file copies which every member of the team must have access to. We couldn’t control access or maintain a master efficiently. As a result, everyone had to be an Excel VLookup expert or we would break this complicated table. The whole process was exhausting.”

“Since implementing OpenBOM our Company has seen significant improvements in a number of areas. Specifically, the amount of hours spent just servicing BOM changes.”

“This time last year I personally spent 5 hours per week on BOM maintenance. It’s now 10 minutes a week. We see that same improvement with many of the lead engineers on the team. OpenBOM frees the team to do the other things that are important.”

Conclusion

OpenBOM gives you a flexible, powerful, and robust calculation mechanism to rollup values. Needless to say that you cannot do it in Excel or any other spreadsheet program because it lacks the fundamental data modeling capabilities – managing items with centralized information for data (eg. Cost, Mass, Type etc.) for each part and also product structure relationships to identify dependencies between assemblies and sub-assemblies.

OpenBOM’s robust and flexible data management capabilities give you the full flexibility of data modeling you enjoy in Excel combined with structured data management capabilities and robust rollup calculations.

Check out how OpenBOM can help you today. REGISTER FOR FREE and start your 14-day trial.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.