Bill of Materials is a fundamental part of the manufacturing company information platform and the foundation of digital thread. It allows you to connect data silos together and build a connected information flow process. However, making this transformation is not a simple organizational and technological process. At OpenBOM we are developing tools that can help manufacturing companies to establish a single source of information and to implement processes to make BOM transformations. Some of these tools are already available in OpenBOM and some others will be coming soon. Let’s talking about EBOM to MBOM transformation, which is one of the most critical among BOM transformations.

How can you transform your Engineering Bill of Materials (EBOM) into a Manufacturing Bill of Materials (MBOM)? In every organization, the Engineering Bill of Materials (EBOM) drives the design and engineering process. The MBOM, on the other hand, is what is used to manufacture the product. The difference between the two? The EBOM includes all the components that make up the end product while the MBOM only includes the components that are needed for manufacturing and purchasing planning.

OpenBOM provides a flexible mechanism to manage product structure (BOM). You can use a one-click BOM function in any OpenBOM CAD Add-in to create an EBOM and later modify it to create a complete multi-disciplinary engineering bill of materials structure including mechanical, electronics, software, and other components and assemblies. Check the power of the one-click BOM article to learn more.

EBOM to Order BOM

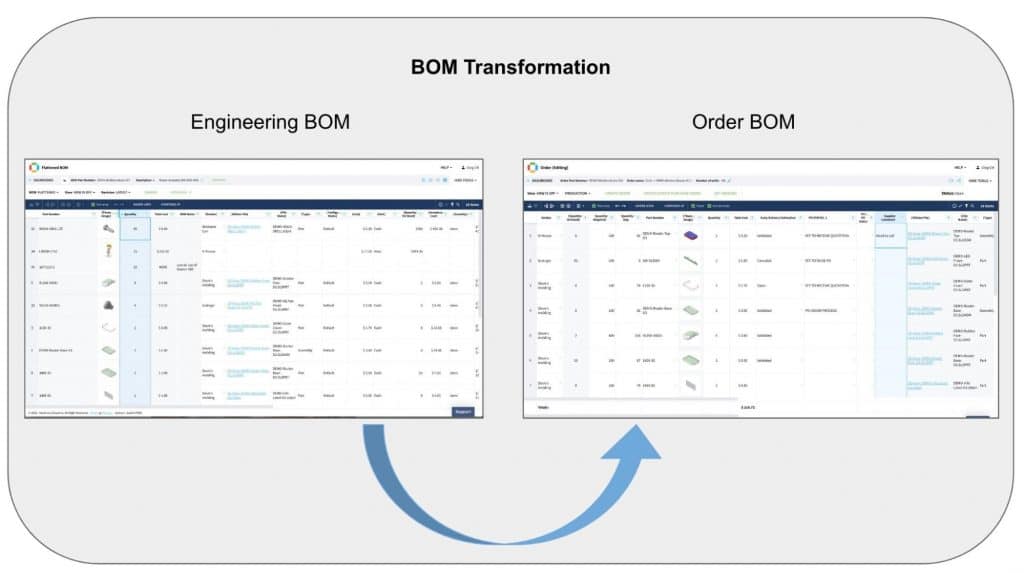

OpenBOM provides a unique combination of engineering and production planning tools. Typically, PLM systems are not focusing on MRP functions and don’t provide inventory and purchasing tools. OpenBOM does it by the creation of Order BOM, which scales up engineering BOM to the number of units that need to be produced and includes all planning tools such as Quantity Required vs Quantity Gaps as well as the ability to choose multiple vendor sourcing. Check more about the process – Inventory and Order BOM Review.

One of the fundamental elements of the Ordering mechanism in OpenBOM is the creation of Order BOM, which is managed in full sync with the Engineering Bill of Materials (BOM). To create an Order BOM, the engineering BOM is flattened and scaled to the number of units in the order, then transformed into Order BOM (sometimes our customers call it “planning BOM”).

Here is a transformation OpenBOM does today to create an Order BOM.

EBOM to Order BOM synch allows the engineering, procurement and production planning team to work together collaboratively and shortens the time an organization spends on ordering and product development.

Another important factor in EBOM to Order BOM efficiency is that both BOMs are using a single shared Item definition that allows keeping in synch important item attributes (eg. vendor, cost, etc.)

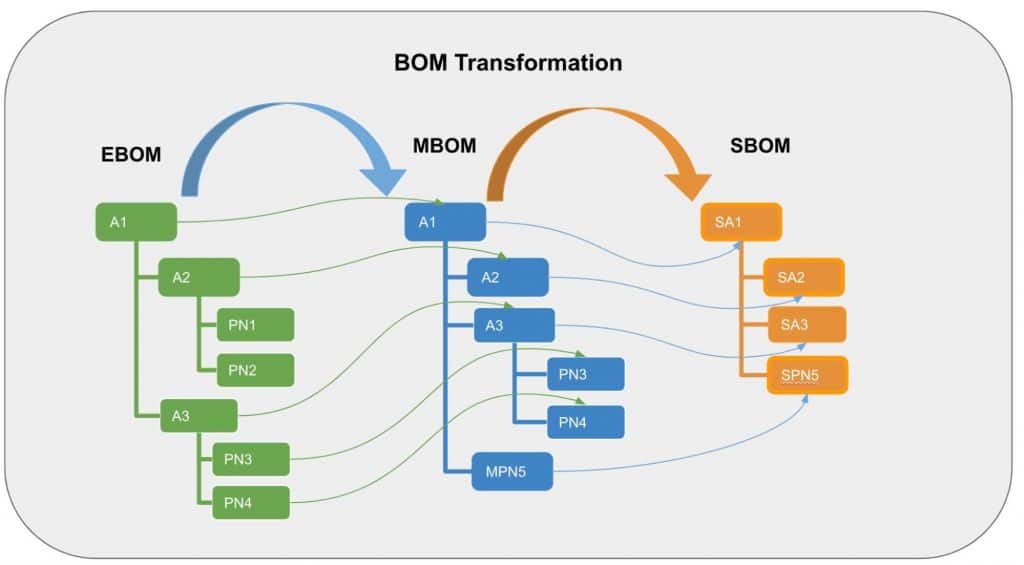

What is coming – xBOM, MBOM, and SBOM

Shh… We will be taking BOM transformation to a completely new level very soon. We are working on big enhancements of OpenBOM that will allow expanding BOM management and collaboration by opening the multi-BOM model of OpenBOM to customers and allowing the creation of different BOM types (BOM) in a flexible way. In such a way our customers will be able to create MBOM, SBOM, and other BOM types and maintain their structure independently as well as support customizable mechanisms to transform one BOM type to another as well as keep them in sync (similar to how EBOM and Order BOM are synchronized today).

The typical process of transforming an EBOM into an MBOM can be done manually, but it is very time-consuming and prone to error. We are going to provide a better way to perform BOM transformation using OpenBOM clone, compare and sync mechanisms.

Conclusion:

At OpenBOM, we are looking at how to simplify complex processes and support a connected information flow between departments and organizations. As such, we created BOM to Order BOM transformation process to connect engineers and procurement functions in the organization to optimize the ordering of components and to connect engineering and procurement data silos. That is only the beginning of the BOM transformation functions we are planning to create in OpenBOM.

We believe in collaboration and transparency. We are inviting everyone who is interested in discovering more about planned xBOM and EBOM to MBOM transformation functions to contact us to discuss your challenges. You will have a unique opportunity to be involved in the process of development and will have early visibility to new OpenBOM xBOM tools and services.

In the meantime, REGISTER FOR FREE and start a 14-day trial to see how OpenBOM can help you today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.