A Bill of Materials is a list of all the items needed to manufacture a product. This detailed list has all the raw materials, components, assemblies needed to create the final product. It can also include the labor to assemble a product. It works as a master structure for everyone involved in the process of manufacturing. That way everyone knows what is required at each stage of manufacturing. Further, we will check an example of a Bill of Materials.

Each raw material is listed in detail so that there is an understanding of what should be done at each stage. The team responsible for manufacturing should be always in constant communication with stores. It is simply not just a list of items needed but also subparts and consumables.

Bill of Materials or as many call it BOMs, are a key function in the manufacturing business. Companies need a Bill of Materials in one way or another during the entire lifecycle from the early design of a product to later manufacturing and maintenance.

In recent years we have noticed that people engaging with Bill of Materials need a different way to present and format them, which is usually driven by their function and needs.

As a result, one of the most frequently asked questions from customers is about the organization of bills of materials, their types, and formats.

In my article today, I will cover the main options you have in the industry and will bring you examples from OpenBOM that support it.

Bill of Materials Examples (including PDF format)

An example of a Bill of materials is a bakery that needs to sell about 1,000 cakes. A BOM for this bakery will include all the ingredients needed to bake cakes, the baking pans, ovens, and packaging. The quantity, overall cost, and needed time should be also included in the list.

Another example of Bill of Material is an electronic company that needs to produce 10,000 phones. The Bill of Materials will include all the components needed, including chips, the quantity, costs, and the model. Also, the time required to have the final product will be included in the BOM.

You can meet different Bill of Materials examples. Here are some of them.

👉 Practical Guide and Examples of Different BOM Type Usage The article walks through Simple BOM, EBOM, MBOM, Support/Service BOM, and Functional BOM with practical examples.

👉OpenBOM: BOM Creation Best Practices. The article demonstrates step‑by‑step how to build and restructure multilevel BOMs (e.g., assembling fastener kits).

What is included in the BOM

The BOM is not only the list of the components but also the quantity of each component required to assemble or manufacture the product. Quantity is playing a key role in the presentation of Bill of Materials information.

Basic Formats for Bill of Materials

Bill of Materials is usually for a specific product or assembly. Some additional conditions can be applied (especially if you work with configurations, multiple vendors, and options).

These are important information to include in the BOM – Part Number, and list of Part Numbers with the Quantities. Keep in mind that Item definition should bring a piece of essential information such as Unit of Measure, Description, and others.

As per the format of the Bill of Materials, you can meet 3 different Bill of Materials representations:

- One level BOM;

- Multi-level BOM (or indented BOM);

- Flattened Part List.

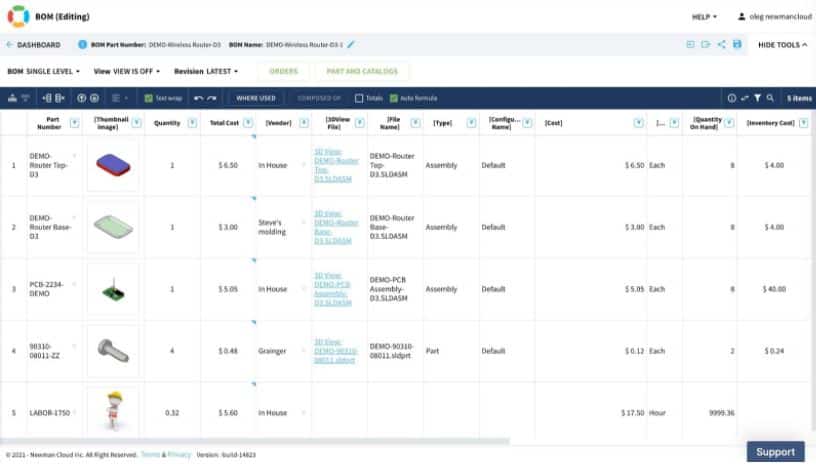

One Level BOM

This is the most simple option and usually presents the items (parts) of the single-level assembly. The items are either parts, materials, or assemblies. The latter are presented as simple items with no sub-levels.

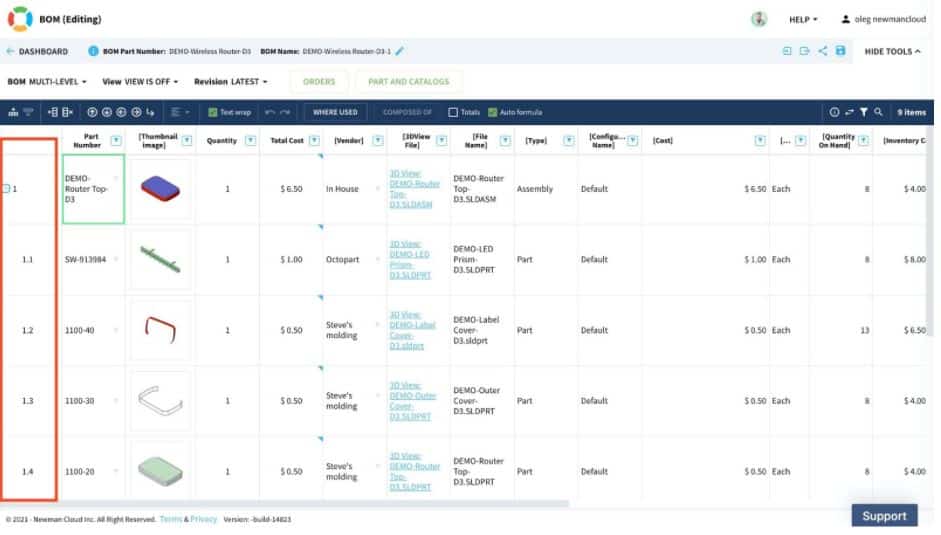

Multi-Level (or Indented BOM)

This is one of the most demanded options and it allows the preset of all items and corresponded sub-levels for assemblies, sub-assemblies, etc. Usually, the most comprehensive, and it presents all the information needed to drill down levels.

When printed on paper, it usually includes levels, but OpenBOM allows you to present them dynamically and drill down to the sub-levels when needed. The number of levels is unlimited.

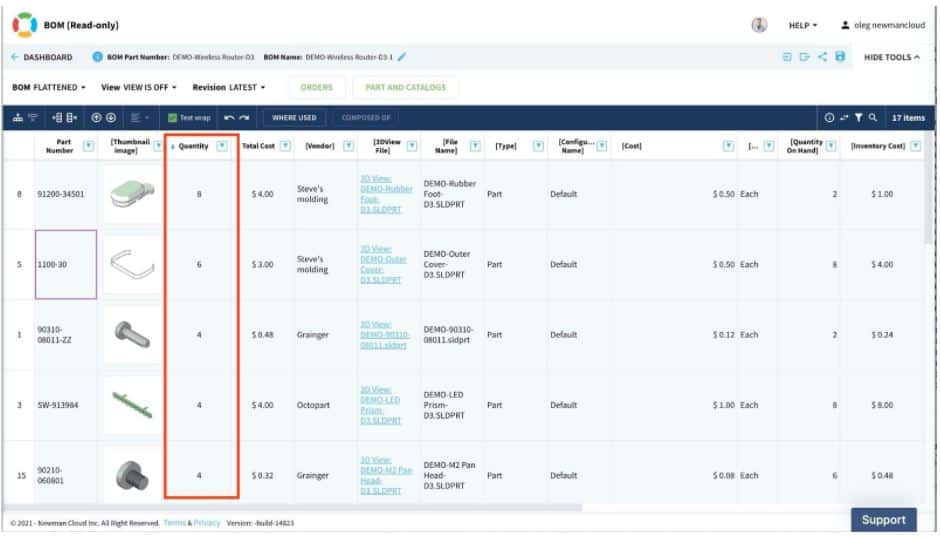

Flattened Part List

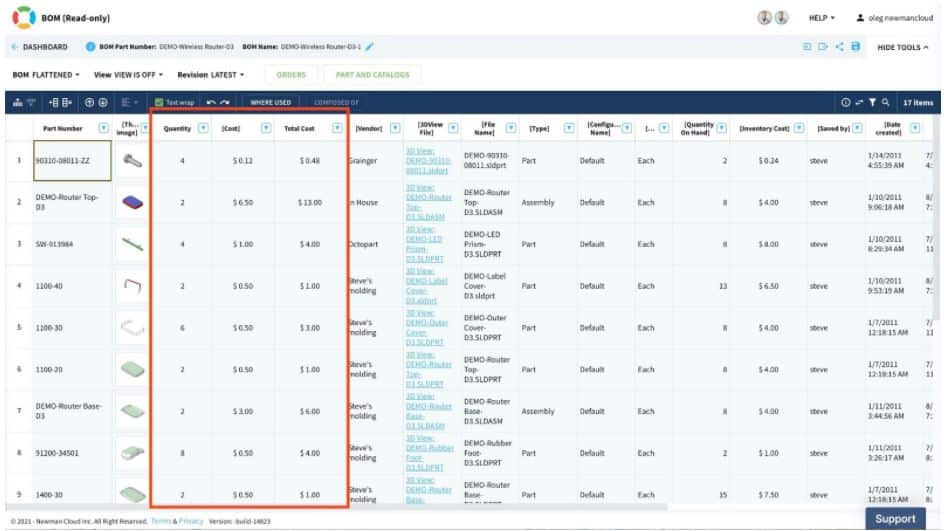

A very useful BOM format is to create a flat list of all items from multiple levels (assemblies and sub-assemblies) with the corresponding Quantities. The usefulness of this format is to have a simple list of all components with the quantities that can be used for purchasing and planning.

Bill of Materials Types

Besides the format, another frequently asked question is about different BOM types. These types are usually representing different steps of product design, manufacturing planning, procurement, maintenance, and support.

Typically the names of the BOMs (types) are reflecting the product development phases:

- Design;

- Engineering;

- Manufacturing;

- Support;

- Maintenance.

There are some other types of BOMs (or names to be more accurate) you can meet. These BOMs are usually representing the product structure and model. These BOMs are corresponding to the ability to represent multiple configurations, a specific (resolved) configuration, or a BOM for a specific Product Serial Number (S/N):

- Configurable BOM;

- Configuration BOM;

- Resolved BOM;

- Serialized BOM.

Sometimes, you can see BOM types that are corresponding to specific “disciplines” in the development:

- Mechanical BOM;

- Electronic BOM;

- Packaging BOM;

- Kit BOM.

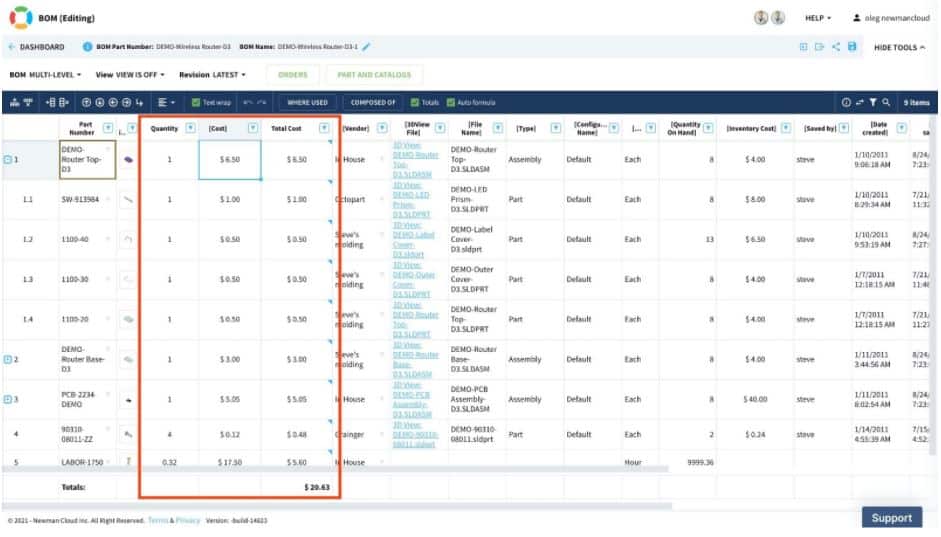

Format and Cost Estimation for BOMs

Some special formats are needed when you want to present calculations and cost estimations using BOMs. The most popular is rollup. The rollup is combining the cost of items (can be anything else – mass, etc.) and rolling it up to all levels. In such a way you’re getting cost presented for all levels. The same calculation format needs to be in both Multi-level BOM and also flattened BOM.

Multi-level Rollup

Flattened (the total per item in all assemblies)

Control and Manage Your Specifications

All types of BOM need to be designed specifically to suit your needs. Whether you use pdf, spreadsheet, or cloud-based BOM, it should contain accurate information about what products you need to manufacture.

You can control and manage your bill of materials through OpenBOM. OpenBOM brings all the vital information such as design, mechanical, software, and electrical components together. Through our services, you can easily track and control production. Streamline production so that customers have only the best products!

Conclusion

Bill of Materials are complex and usually reflect the complexity of the product development process and the complexity of the product itself. It is extremely important to set the right language and definition in the company, which will simplify the communication and streamline the process.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.