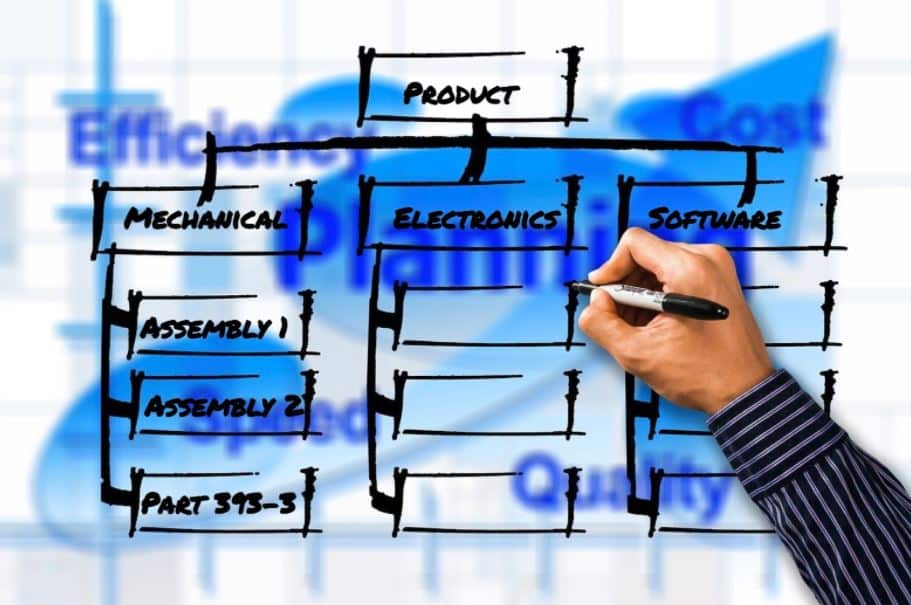

A bill of materials is a full list of items (materials, components, assemblies, labor, etc.) required to assemble or manufacture any product.

It can be applied to any type of product – mechanical, electronics, construction, food, etc. It can even be applied to service projects and in this case, it will remind you of a work breakdown structure.

Engineers, manufacturing planners, procurement departments – all of them are using Bill of Materials in their work, so, getting it right is crucial for smooth process management.

In my previous article, I shared my thoughts on why Excel is not a good way to organize product information. I also touched on what it means to manage BOMs these days and why modern digital manufacturing methods make it so that a new way of organizing and managing Bill of Materials is essential for success.

Create a Digital BOM Record

Important principles of Digital Bill of Materials

- A centralized source of information about all items

- Managed records of BOMs, revisions, and changes

- Structure and Re-use

- Real-time data sharing (no emails, no copies)

There are many different types of Bill of Materials that a company can be using. Even so, I recommend focusing on two main bills of materials types: (1) Engineering; (2) Manufacturing Or Planning.

If you’re using different applications, you can see the Bill of Materials there (eg. CAD, PDM, ERP, SCM). Nothing wrong with that, the Bill of Materials can live anywhere.

However, the important thing is to organize the digital process of managing the Bill of Materials in a way to ensure you have a single source of information about the product and you don’t need to search for “the right version of the BOM” hidden in the specific application or Excel files that was sent by email.

Otherwise, your product development and manufacturing process will halt and you will incur an additional cost for changes.

Typical Elements of Digital BOM – Items and Instances

What are typical elements of the information you might need in your digital records?

Let’s start from the separation of two main types of records :

- Item Record

- Instance Record

The first (Item Record), describes all parameters of the item that are THE SAME for all places in your product where this component is used. Think about a screw or an electrical motor you buy from external suppliers. Here is a sample of the typical information you would need to include in your Item definition.

- Part Number

- Name

- Description

- Unit of Measurement

- Cost

- Manufacturer

- Manufacturer Part Number

- Supplier

- Supplier Lead Time

There are some others, but the properties above are a great starting point. Some tools like OpenBOM give you an option to save.

The second (Instance Record or sometimes BOM record) describes the data about the item in the context of a specific Bill of Materials. Think about a specific Item instantiated (inserted) in the BOM and used. You need to be able to manage these properties separately.

A typical set of properties used for an instance (BOM) record are include but are not limited to these properties.

- Quantity

- Reference Designator

- Location

- Calculated Cost

- Supplier

Why avoid Excels and old-fashioned BOM tables?

Product structure is dynamic data that needs to be managed properly. By walking away from Excels and drawing tables you put a foundation to digital records and eliminate redundancy and multiple mistakes that can be found when you attempt to manage Excel files and share files via emails.

Check OpenBOM user experience – it is as simple as Google Spreadsheets or Excel, but it gives you a power of digital BOM and powerful database engine of OpenBOM application.

Conclusions

Creating digital records for your product is an essential part of digital product development. Relying on Excels and Drawing tables can give you an illusion that “work is done”, but eventually will lead to mistakes, additional cost, and delays.

Check how OpenBOM can create a full digital Bill of Materials online. Click HERE to register for FREE to create an account.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.