Bill of Materials is the lifeblood of every manufacturing company and business. However, when it comes to the data, manufacturing companies are usually facing many challenges related to how this data should be organized, stored and managed

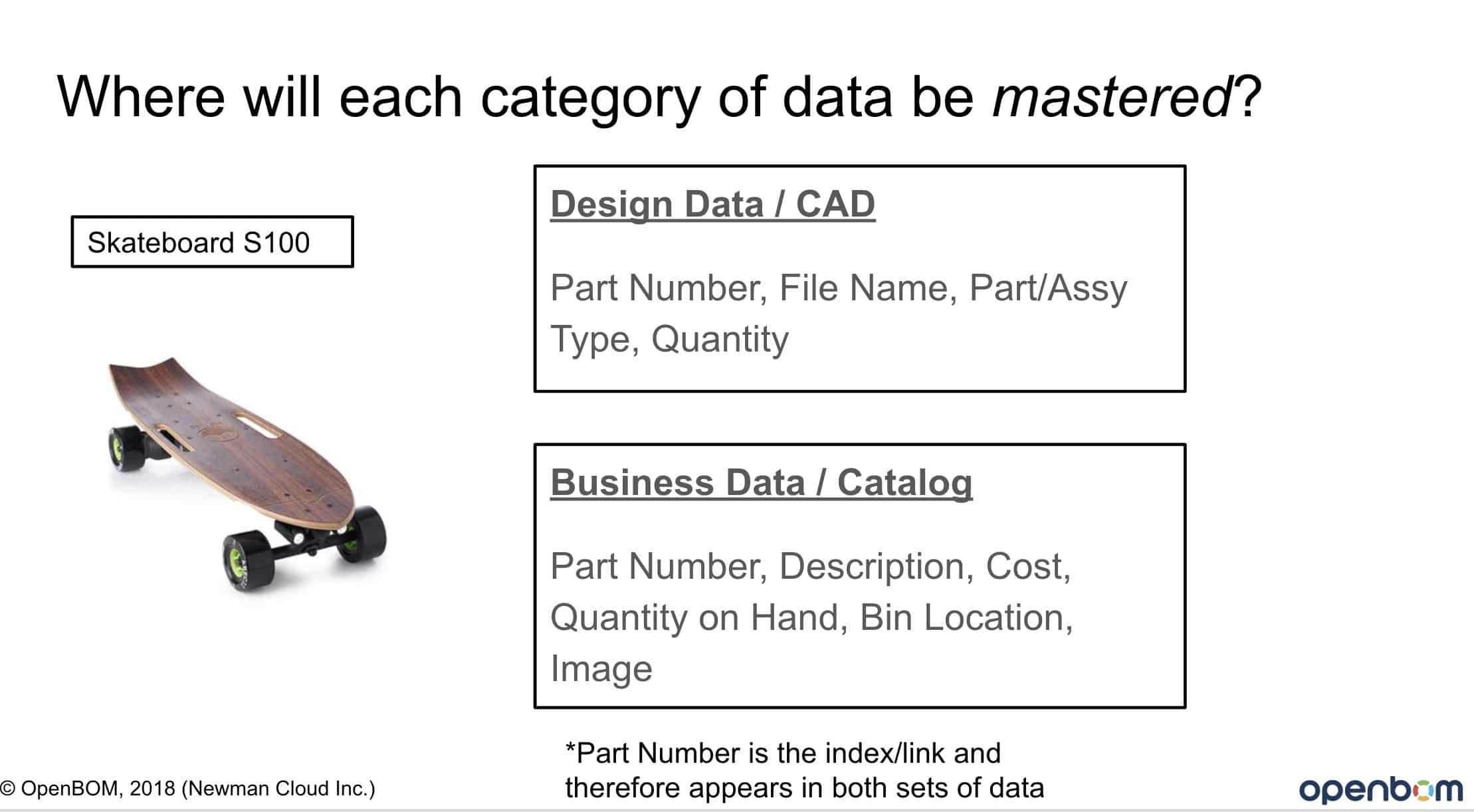

For many years, CAD was an ultimate tool to store all information. This is usually a place where data is born (design) and naturally stored. However, as we move forward towards the definition of data elements, the question about the separation of data into manageable pieces is becoming more important.

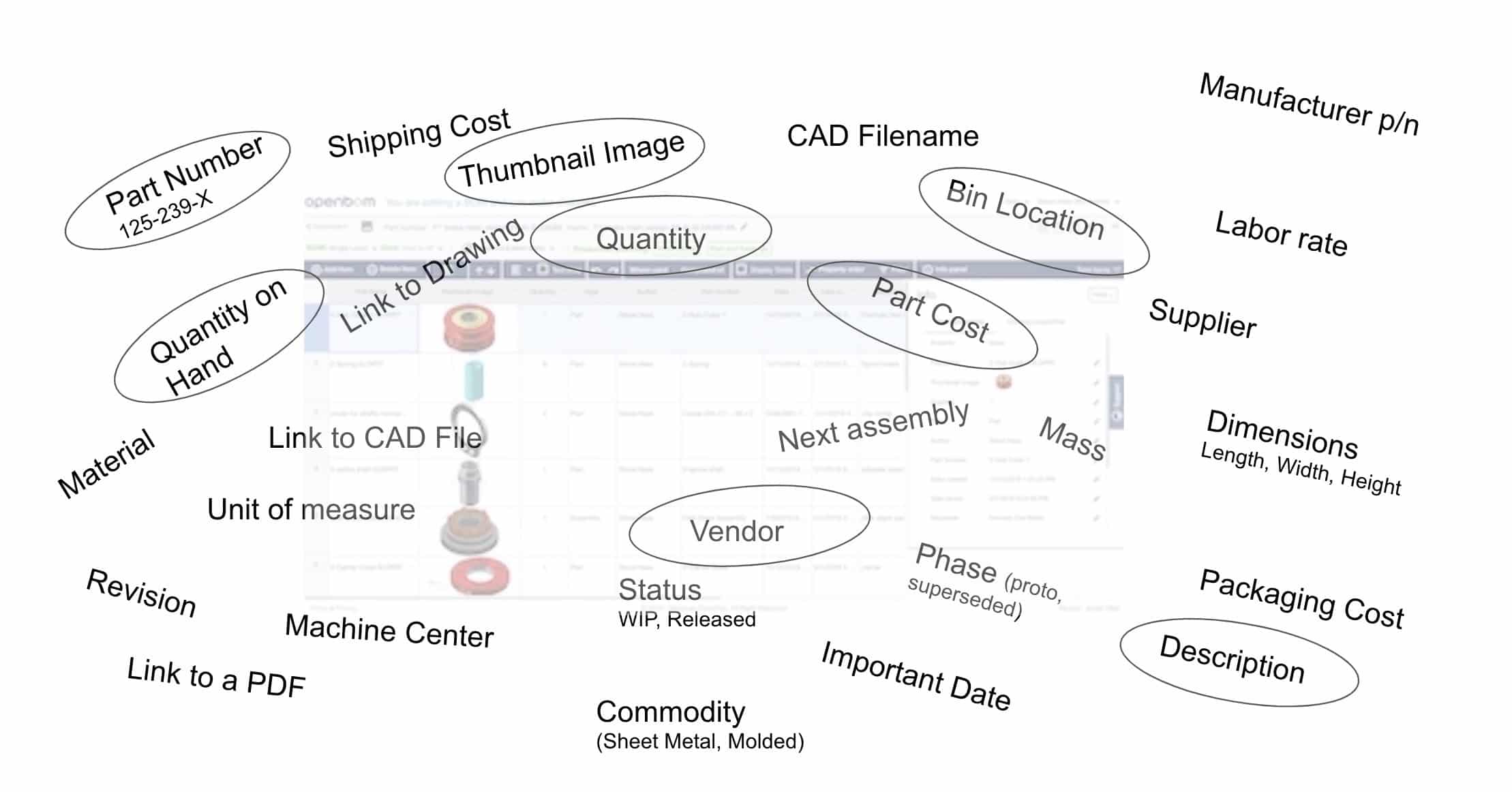

The first step in this process is to decide what data do you need. Typical set of data parameters such as Part Number, Description, Unit Price, Quantity, etc. comes easy. But there are many other pieces of data.

Earlier this week, we organized a webinar where we discussed how to organize data, what data needs to managed and what are options to store it.

Here is a video

Here is a slide deck

The Bill of Materials is a complex set of data that must be organized and managed. It requires some planning. Don’t skip the planning, otherwise, you will find yourself in the middle of the data management crisis trying to decide what data attributes you need to manage in the Bill of Materials. Do you have a BOM topic you want us to talk about? Please send topics for new webinars to support at openbom dot com.

Best, Oleg @ openbom dot com.

Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.