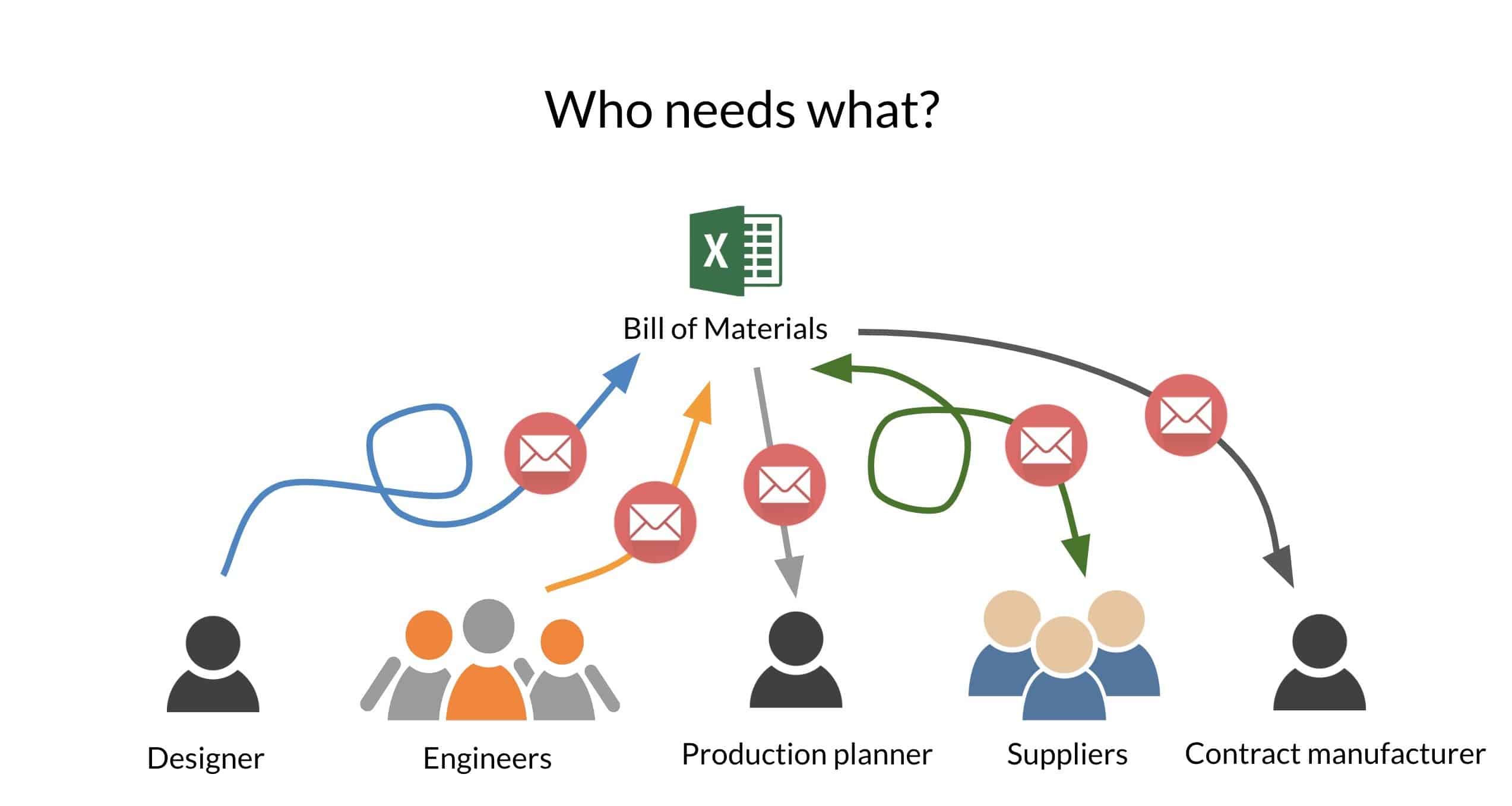

Everyone needs the information that is in the Bill of Materials. But everyone needs it to be delivered differently. Engineers might have an access to all assemblies and sub-assemblies, descriptions, technical information about parts. Procurement has information about suppliers, contractors, and cost. How to balance all this information together.

Typically. Organizations are struggling with the data. It comes from siloed enterprise systems or the absence of these systems. Data is not located in a single place. People are taking the data they need and offload it to Excels they can control. This is not a good way to share data.

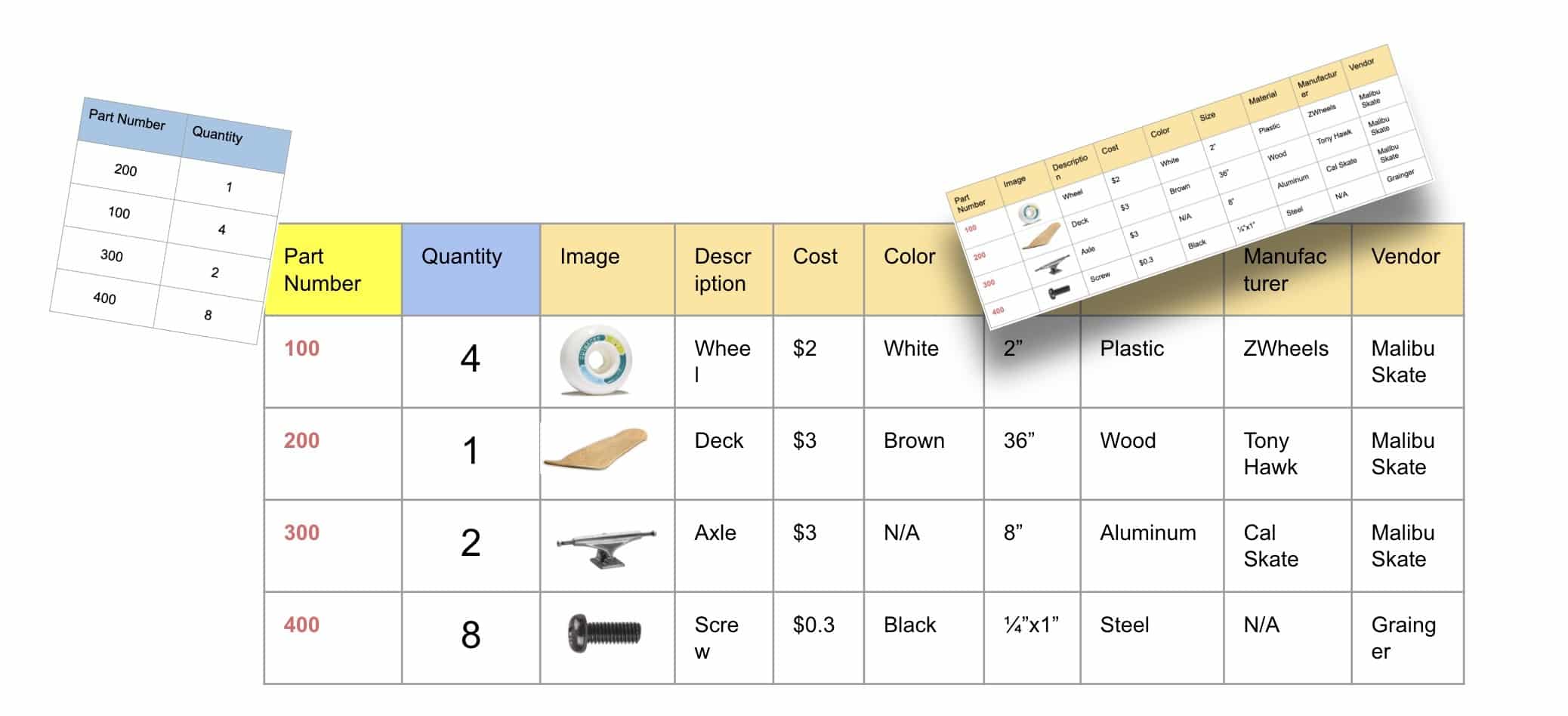

The fundamental data management principles of BOM management and product development are Item and Usage. Sometimes we call it Reference-Instance. The main point is that Item (Reference) represents all common information about parts. Eg. the screw cost and description are the same in all assemblies and sub-assemblies. But Quantity is not. In such a situation, Quantity is an instance (usage) information.

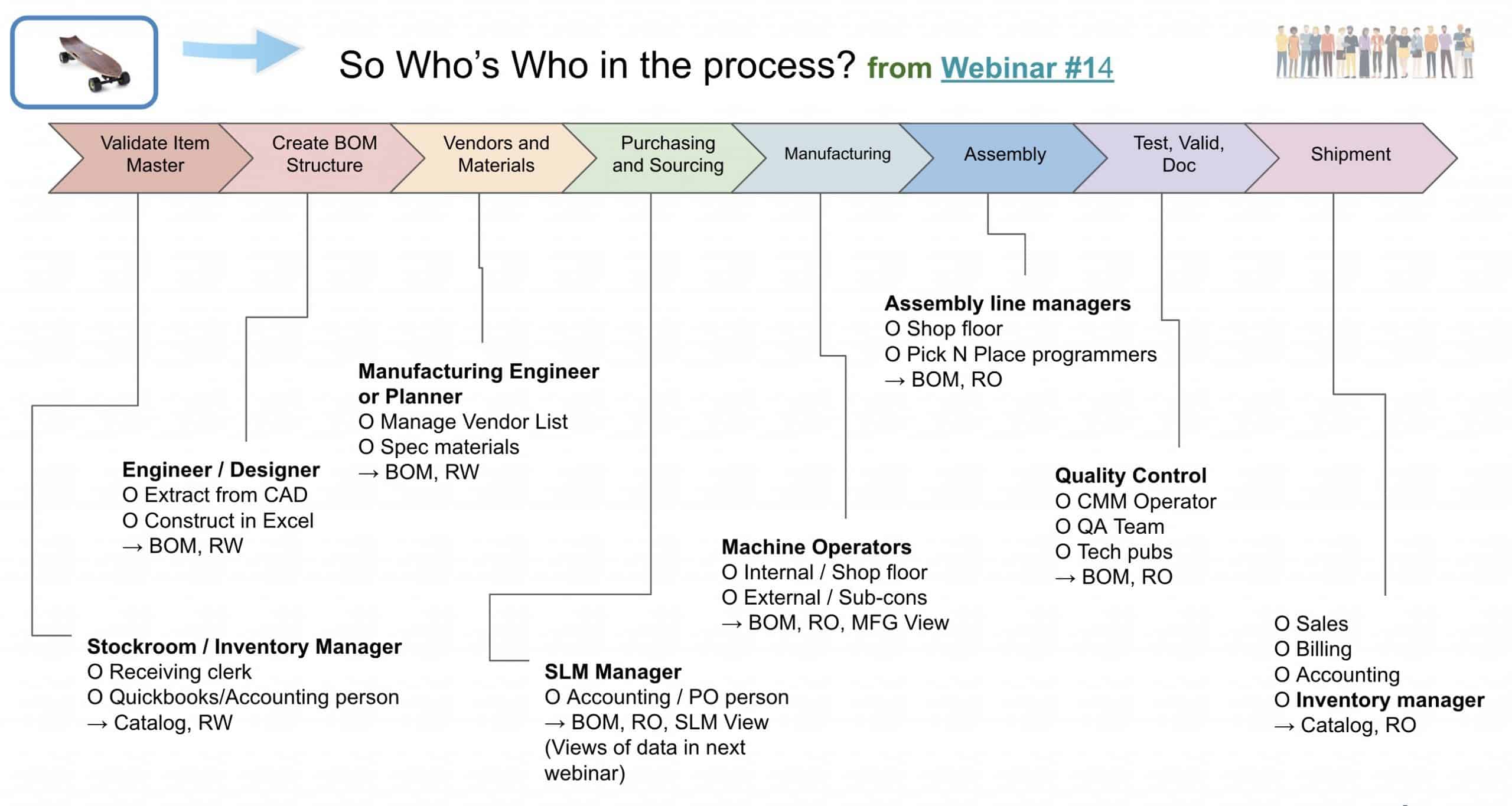

To think about who gets what, let’s take a look at the overall process.

As you can see the needs for information are different. Therefore, a good idea is to define roles and what information can be available. User-defined views is a good way to think about what information is available.

Check this video from the webinar for more details.

And watch video recording from the webinar.

And this is a slide deck.

Conclusion.

When you think about product development and manufacturing, you need to image different roles and information that belongs to these roles. That would be your roadmap on how to plan data access. Bill of Materials can be overwhelming with the complexity. Therefore to bring the right data at the right time is a way to go.

Best, Oleg @ openbom dot com.

Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.