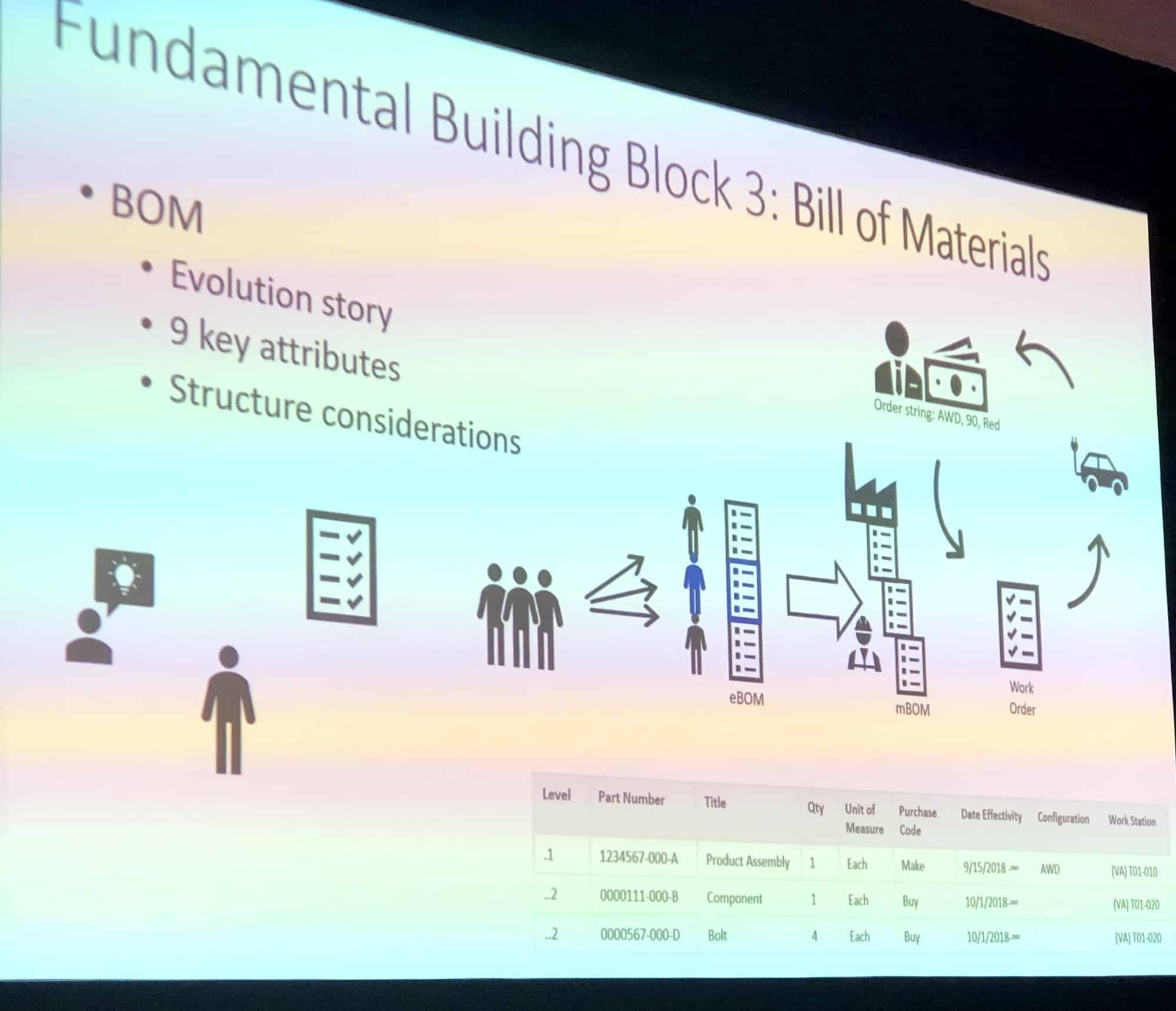

You can think about the Bill of Materials as a flat list of parts placed in the drawings. This is a simplistic and wrong way to think about the information. Here is a slide deck I captured a few weeks ago at PI PLMx in San-Diego by Rick Chang, Director – Enterprise Methods and Tools, Faraday Future.

While nothing is wrong in presenting a BOM as a list, this is only a “presentation view”. Inside, BOM is much complex and it is related to how you manage information about product structure, parts, and properties.

It made me think about how to get back to basics and explain some fundamental things about how to manage data about parts, part usages and BOMs.

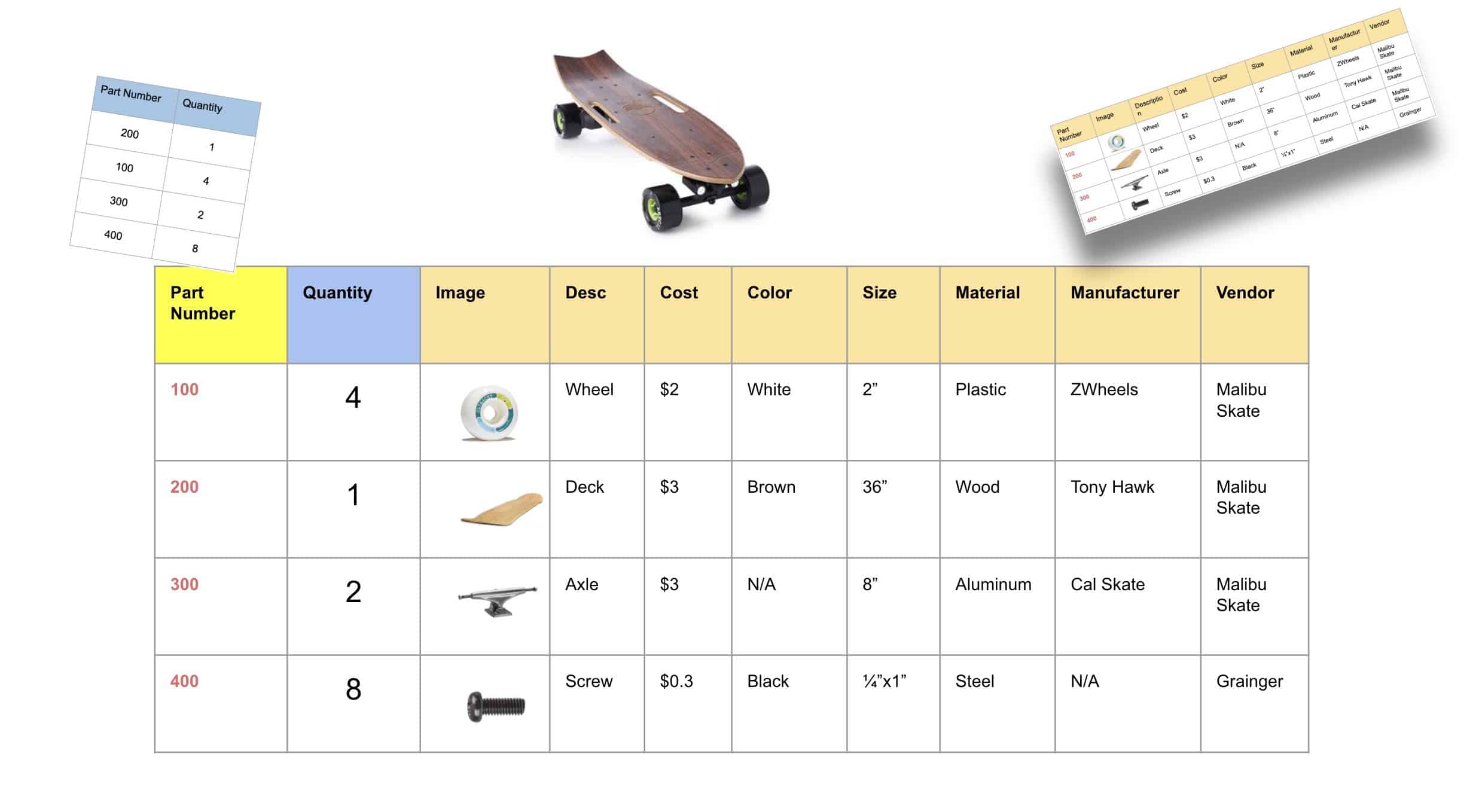

The slide deck and webinar are doing exactly that. We describe a few important elements of BOM management – Item (Part) and Reference (Part Usage). Every line in the BOM is associated with the part. These parts are represented by data (properties). Some of these properties are the same for all usages of Parts and some of them are not. How to manage it? Check our slide deck.

Here is a quick summary:

1- Each part has properties that will be the same all the time – Size, Manufacture, Cost, etc.

2- Part can be used in multiple Bill of Materials (products) and in such cases, there are some properties that can be different in each BOM – Quantity, Reference Designator, Calculated Cost.

3- The data about Part and its usages must be managed separately to prevent duplications. In OpenBOM we call it a reference-instance model. However, you can find some other names as well.

Conclusion.

Planning how to manage data is important. Excels are good because you can through data in Excel and move fast. But within time, the data in Excel will be messy. The advantage of OpenBOM is that it gives you an easy paradigm to manage data about Parts, Usages and BOMs to prevent data redundancy and at the same time, by managing data in a simple and easy way.

Try OpenBOM today by registering to FREE OpenBOM User Subscription.

Best, Oleg @ openbom dot com.

Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.