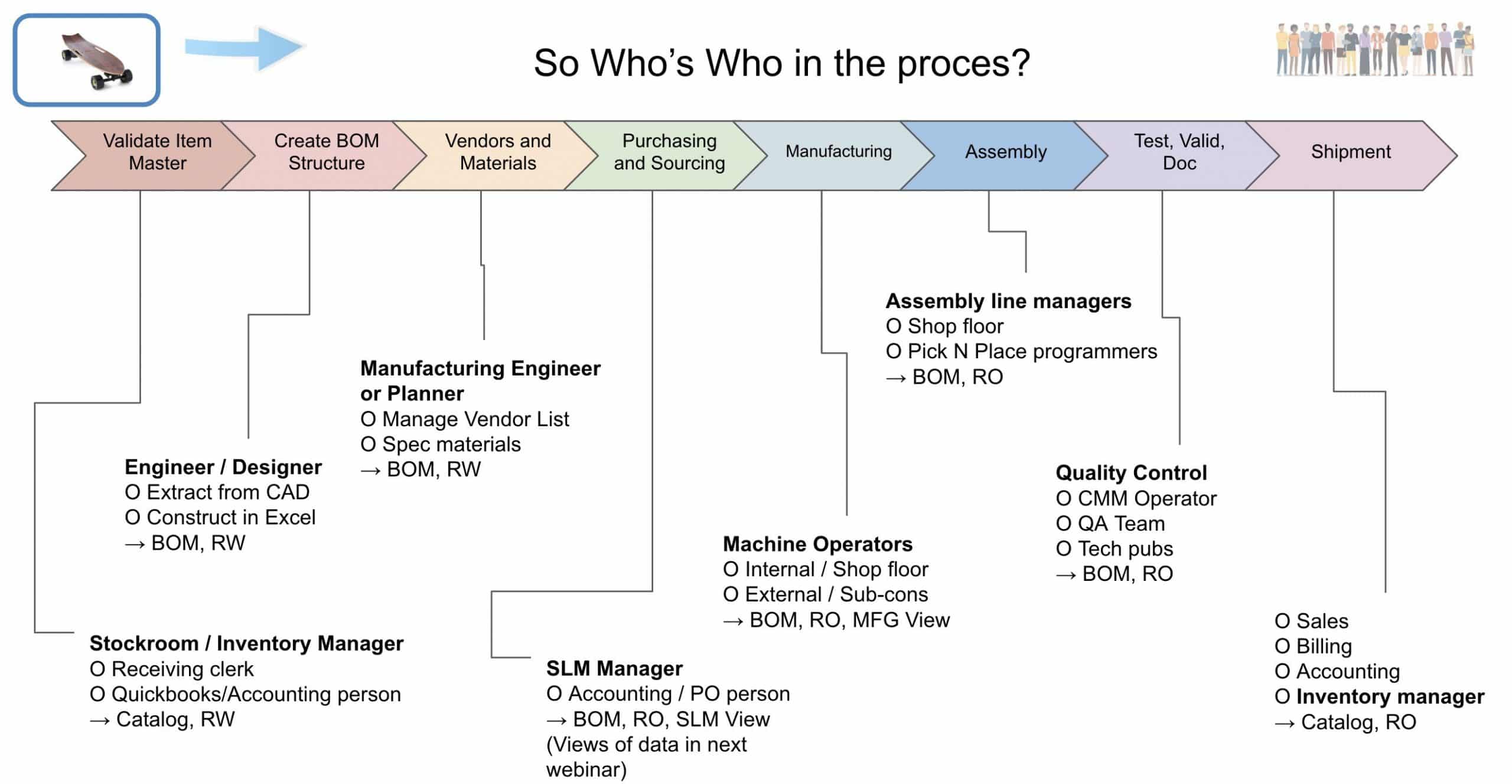

This week we continued the serious of “BOM Basics” webinars and speak about people. Yes, I always like to say that technologies are easy, but people are hard. Bill of Materials Management is teamwork that requires the coordination of many people in the single process of creation and use of information in the bill of materials.

The information in the bill of materials is belonging to engineers originally creating the product, manufacturing planners who work on the process of manufacturing and production, purchasing people involved in the process of buying parts or outsourcing the work.

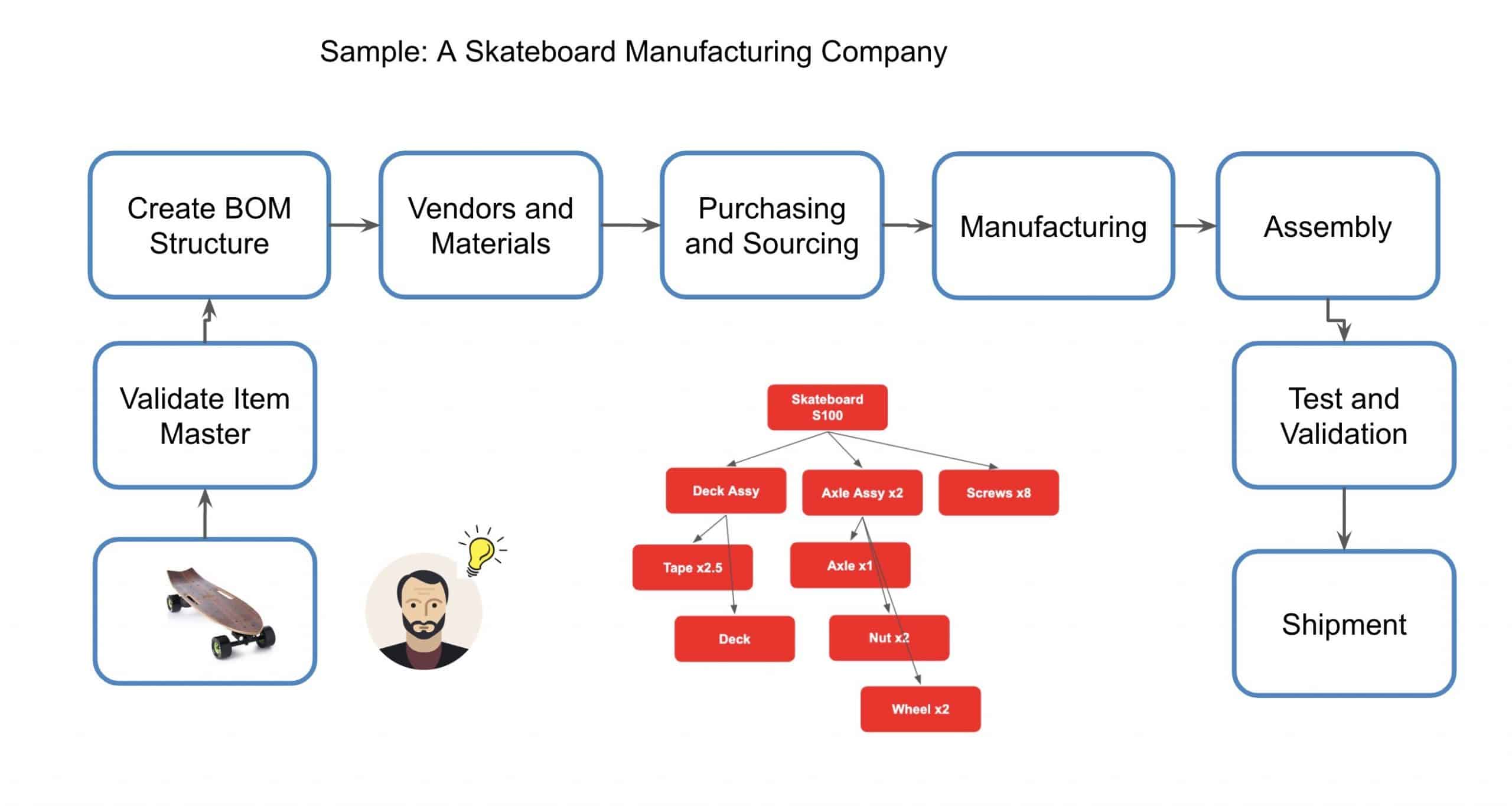

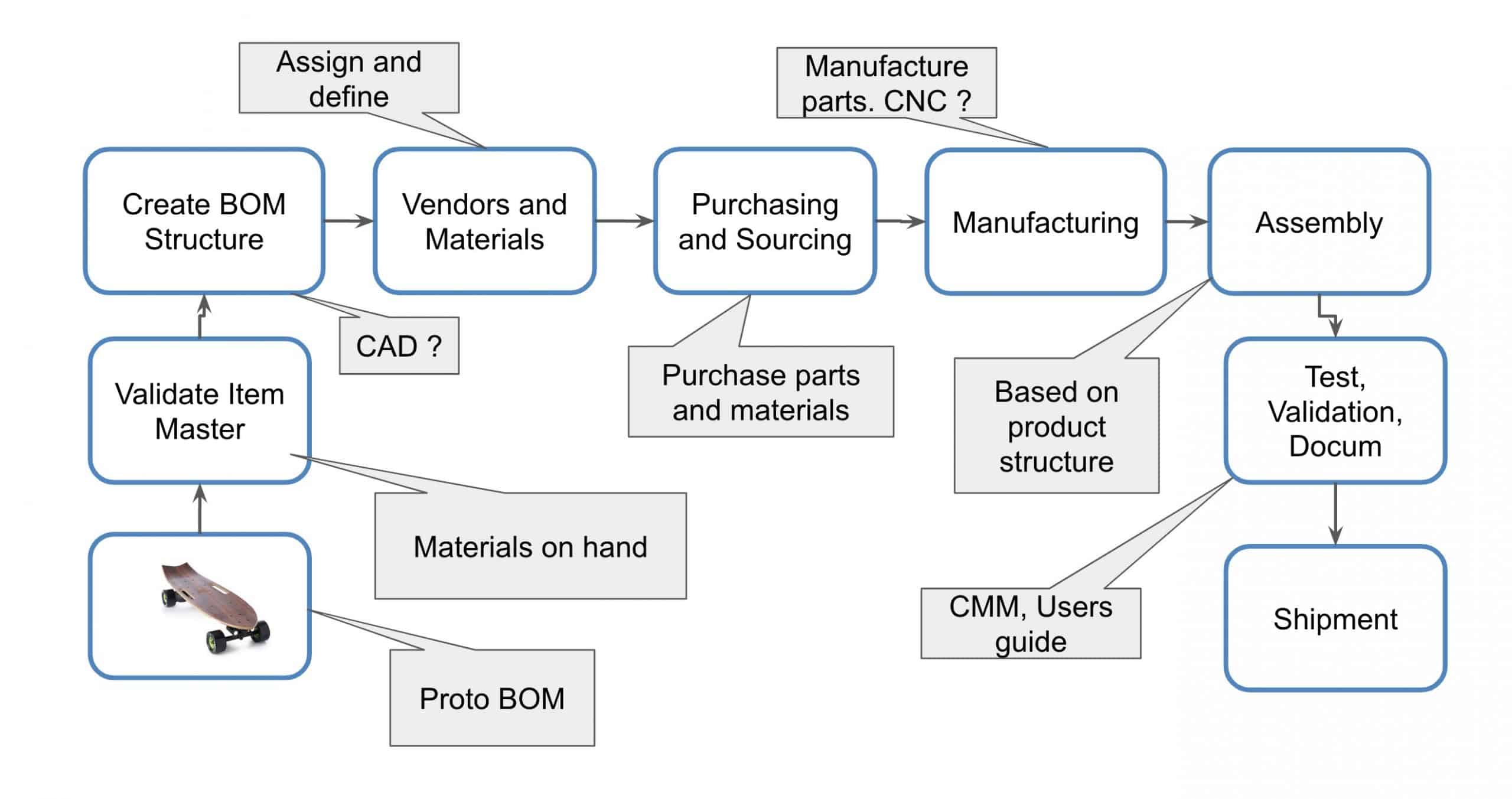

Here is an example of a Skateboard manufacturing company.

Who are those people involved in a process of designing, engineering, planning, assembly and final shipment of the product?

Finally, the process looks like the following picture. Check who are the people (or departments) involved.

Check the slide deck from the webinar here.

And watch video recording from the webinar.

Conclusion.

Bill of Materials is the lifeblood of the product development process and practically everything in manufacturing. A company is using BOM to organize information and coordinate people. It is an essential piece of the information you need to succeed in manufacturing. It is important to share BOM and related information to keep people on the same page (or you can say on the same BOM :)).

Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Try OpenBOM today by registering to FREE OpenBOM User Subscription.

Best, Oleg @ openbom dot com.

Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.