Digital Thread implementations are on the rise in manufacturing. Companies are moving to a digital era and looking at how to establish seamless information workflows, eliminate old fashion document-driven operations, and switch to online systems that can be available to everyone and everywhere. Many companies are looking for ways to improve factory communication and operations. OpenBOM offers a suite of online services that helps connect different parts of the product development process – design, engineering, production, and procurement.

With OpenBOM, companies can build a digital thread that improves communication and collaboration between suppliers, designers, engineers, and manufacturers. In our recent article, I talked about how the new OpenBOM Drive extends the digital workflows for customers using OpenBOM by adding an ability to bring CAD (and other files) under control and associate catalog item records with files located in Drive. Today, I want to give you a bigger picture of how OpenBOM manages the information and connects the silos.

Product Development and Digital Thread

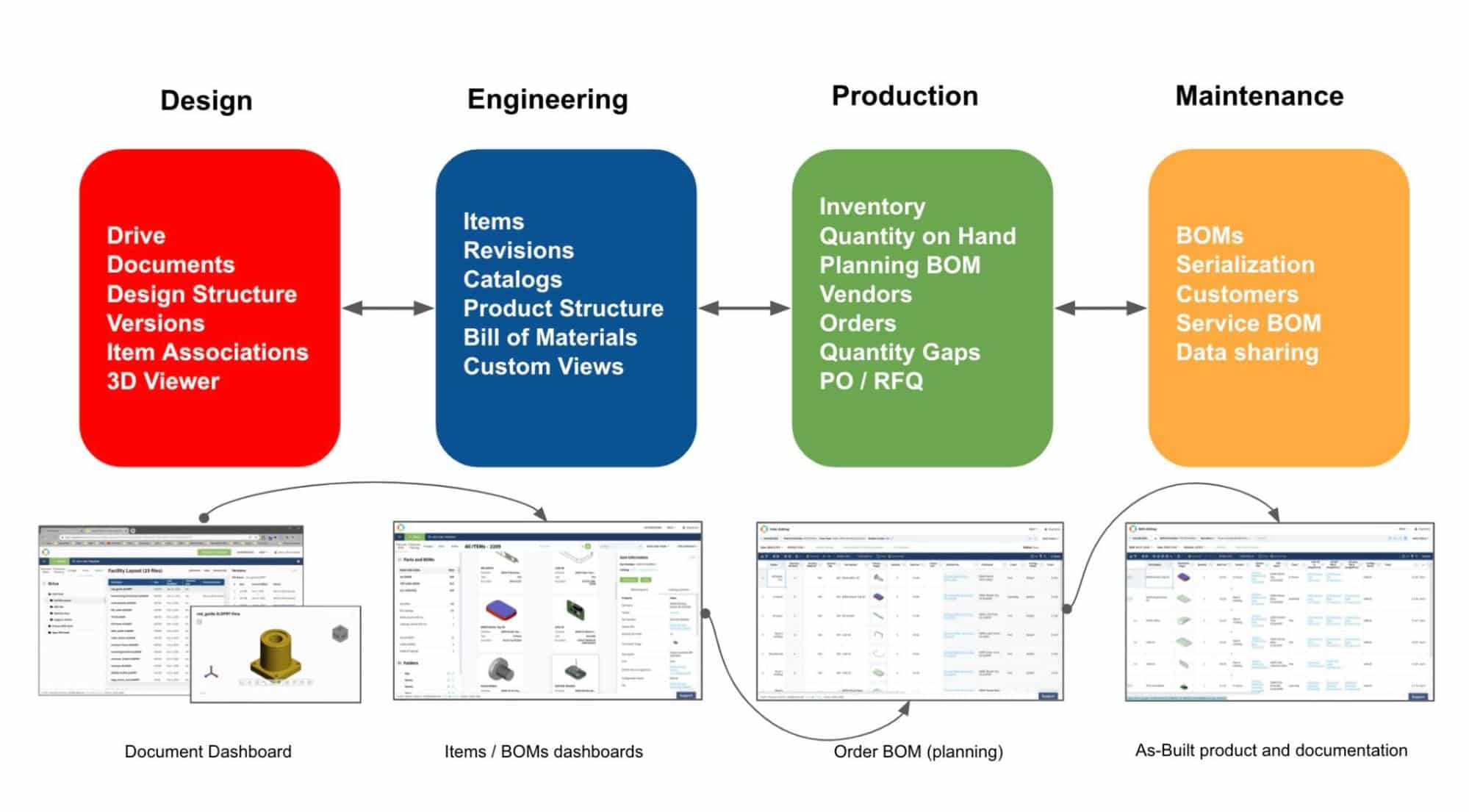

OpenBOM flexible data model allows you to create and maintain the product representation information in a variety of forms and stages during its lifecycle. It starts from the design where OpenBOM Drives allows you to manage files and keep a structure of documents and their versions under control. For engineering, OpenBOM allows the management of Items, BOMs, revisions, and maintaining the history of changes. Moving to production, OpenBOM allows performing the planning and ordering process. Finally, once the product is released to the customer, OpenBOM allows you to keep the information about product records and their changes during the maintenance process.

All pieces of information are intertwined and OpenBOM supports the way for people working on different data elements to connect and collaborate in real-time.

OpenBOM Services

The functions described above are supported by multiple system components in OpenBOM and data structures. These components and elements are functioning together and collaboratively allows a customer to perform their data management tasks, create objects, collaborate, save and update information. Below, I will give you a quick summary of the main OpenBOM services and components.

Drive

This is a virtual drive (currently available in Beta) allowing you to manage files, collaborate in real-time, perform vaulting and version management. Available via Windows File Explorer, Web dashboard, and CAD Add-in interfaces, Drive allows you to keep document structure and associate it with items and BOMs created downstream.

CAD Add-ins

Design is a cornerstone of product development. Therefore, managing design information is extremely important. OpenBOM CAD Add-ins allow you to capture design information, including files and all derivatives, and store this information in the OpenBOM cloud service.

BOM Management, Configuration, and Change Management

A core of OpenBOM – Item and BOM management provides a flexible data foundation to manage product structures, revisions, changes, and attached files (eg. specs and CAD files). All together, it creates a representation of the product structure that provides a single source of truth for all people involved in product development. It is visual and collaborative. It allows all team members, contractors, and suppliers to work together. Configuration and change controls support the process of provisioning, change requests, and approvals. BOM structures can be serialized and used for “As-built” product structures to support maintenance and support processes with customers.

Production and Procurement Process

Order BOM (or planning BOM) is a foundation of the production planning and procurement process. OpenBOM manages inventory levels, allowing you to create orders from catalogs and BOMs as well as to perform RFQ/PO process with suppliers and contractors. Order BOM structure is tightly connected with product structure and can be synched at any moment of time when changes are happening.

Conclusion

OpenBOM provides a set of robust services and digital tools to manage entire product development, design, and product planning processes. The information managed by OpenBOM is intertwined and OpenBOM collaborative tools provide an easy and simple way for people to perform their tasks and communicate. All together, OpenBOM data platforms allow the creation of a connected information set, which helps to streamline processes and information exchange.

Check out how OpenBOM can help you- REGISTER FOR FREE and try a 14-day free trial of all our services.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.