Data management is a big topic for all engineering teams and industrial companies. According to many reviews, engineers are spending more than 50% of their time on information and other data-related activities such as extracting, formatting, validating, and sending information downstream and upstream. Old data management habits are still powerful for manufacturing companies and therefore engineers and management are in the continuous clash of activities – how to prepare the data and how to make the data useful.

The dilemma is really painful – engineers can manually enter data and maintain Excel files or focus on the development of future innovative products. The outcome is painful – companies are continuously struggling with getting access to the right information, existing data management practices are slowing teams, and IT and PLM architects are getting requests about data management improvements.

Product complexity is another big problem for most engineering teams. Modern products are a mix of mechanical, electronics, and software elements together with cloud services and heavy dependencies on people in other companies (design contractors, manufacturing contractors, and suppliers). Organizing data management workflows in this reality is a big deal mainly because the traditional data management was oriented on a single CAD system and vaulting files using a local PDM vault.

Old Data Management Practices

In my article last week, I was speaking about the industry trajectory of CAD data management development. CAD files are still a core and fundamental part of data management organizations. Although CAD file vaults (PDM) are growing in popularity they cannot provide a reliable mechanism to support data information workflows downstream and across the value chain. Most cloud PLMs were designed not to provide integration with CAD data management and cloud CAD progress is still too slow.

Altogether, it presents a super painful problem – how to organize the information flow between engineers, production planning, procurement, contractors, and suppliers. Old fashion methods of extracting Excels, sharing files via emails, and cloud file storages are not efficient and the information flow is a big mess in companies of all sizes.

Cloud Services and Information Flow

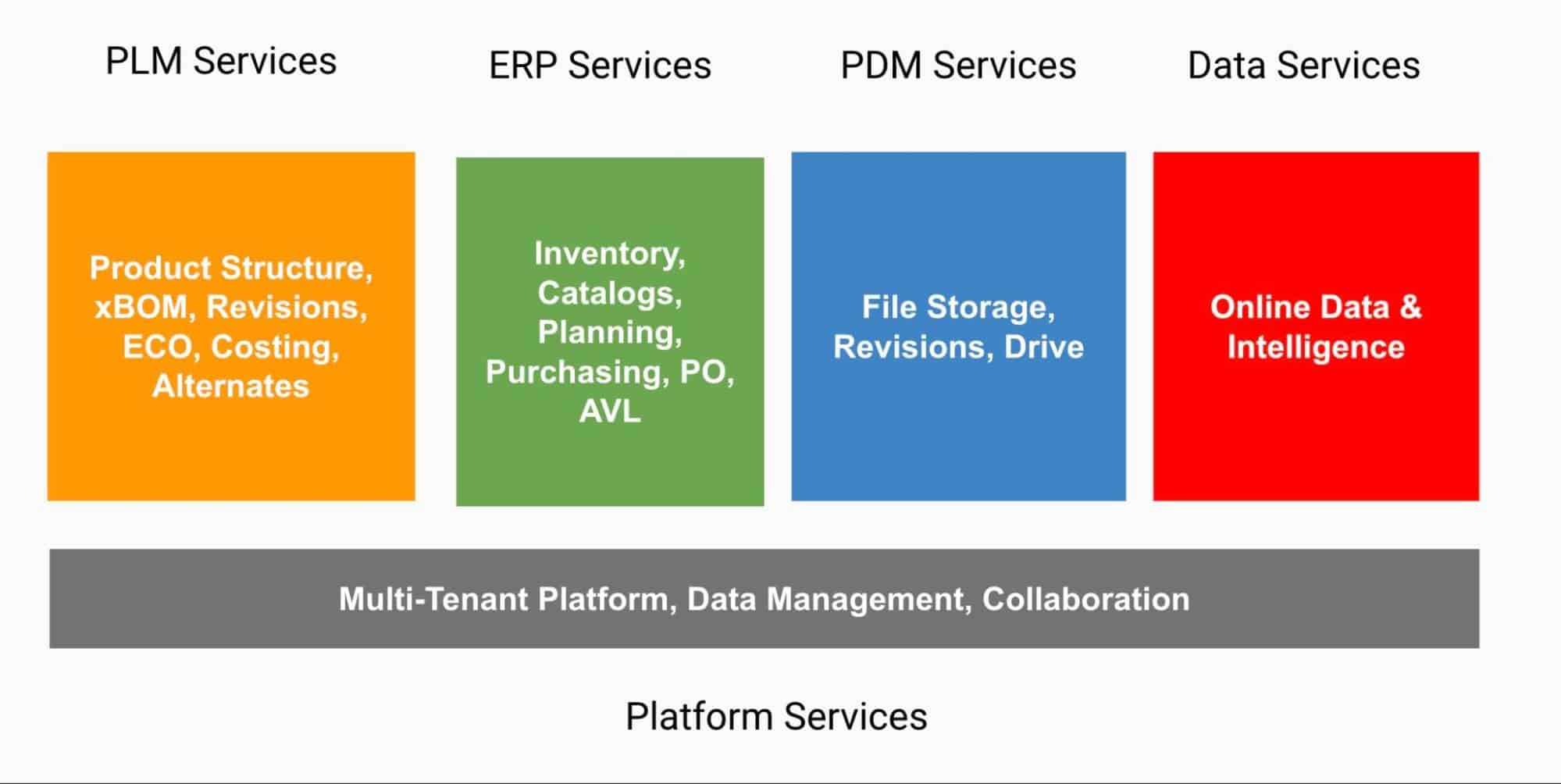

Companies have to move away from old fashion data management practices and setting up new services is the most important step to organize and optimize data flow. It is a holistic shift that provides a new foundation (multi-tenant online data services) capable of interacting with CAD systems, turning existing desktop solutions into online data services by SaaSification or desktop-based solutions to support modern digital workflow. These cloud services can seamlessly integrate with cloud/SaaS CAD systems and also speed up cloud CAD adoption.

The foundation of these new cloud-native platforms is a multi-tenant data management, micro-service architecture, and polyglot persistence database architecture. Together, they provide a scalable global platform capable of integrating with existing multiple CAD systems but providing seamless SaaS user experience and scale to support multiple engineering teams, contractors, and suppliers

OpenBOM Services

OpenBOM brings a new type of cloud service that can be used for different purposes. The services are available with different subscription options and can be used with a high level of granularity to set up a new data flow.

For the purpose of this article, I want to talk about the foundation services and part of PDM and PLM services providing integrations to manage CAD files, to extract information including files, organize it and make it available to everyone in the organization for downstream and across the value chain (design contractors, manufacturing contractors, supply chain). Check out the number of integrated CAD tools with OpenBOM. By setting these integrations, OpenBOM services are providing seamless access to information.

Here are the 3 ways OpenBOM services can be used to optimze the information flow:

CAD services

This group of services is responsible for the seamless integration of desktop and cloud CAD data and tools. The information is flowing from desktop data sources and data management tools become available online. By doing so, OpenBOM eliminates the need for old fashion CAD Excel exports and ongoing routine tasks of “Excel management”.

Data Sharing

OpenBOM patented BOM collaboration methods are used for instant data sharing and seamless data access by individual users as well as role-based data access. Everyone is getting the right data, no manual updates are needed, all changes are happening in real-time with no delays. Think about all emails with Excel attachments – you don’t need them anymore.

Release and Change Management

For a more structured change process, OpenBOM change management provides unique collaborative approval workflow methods. This service provides a customizable approval business logic and collaborative access for everyone to review, approve, and notifications about all changes. No more parallel Excel approvals, files sharing, email confirmations. OpenBOM online platforms give you a new information flow.

Customer Examples

OpenBOM helps thousands of companies across the globe organize the data and optimize the information flow.

OpenBOM helps rfIDEAS to streamline its communication and data sharing with contract manufacturers.

“Our primary use of OpenBOM is with our contract manufacturers”, says Craig Zerwas, the company’s Engineering & Operations manager. OpenBOM delivers the proper information to our CMs”, Craig explains, “it’s just that simple.” According to Craig, “OpenBOM speeds the ECO process and reduces build times. All information is in one place. No emails with the ‘final final final excel attached’, it’s way less confusing for our CMs.”

Another story – Mechasys Reduces The Number of ECOs by 35% And Streamlines NPI Processes Using OpenBOM.

“Leaving Excel behind has had other benefits at Mechasys. The company is transitioning from R&D to NPI. We need an accurate, structured BOM to communicate with our supply line and the manufacturing team. We love OpenBOM for our engineers. Our Engineers import CAD data using the OpenBOM add-in and the rest of the team consumes it in the planning process – it’s that simple. Reflecting back on our implementation with OpenBOM I can say the results have validated our choice to buy OpenBOM. We reduced the number of ECOs BY 35%.”

The last story is from Kapsch BusinessCom, which has over twenty years of successfully implementing international projects quickly and easily, making global presence possible for their clients.

“OpenBOM has reduced our engineering time by 30% and significantly increased my teams’ effectiveness,” says Roland. “Prior to OpenBOM, we struggled with multi-level Excel files which stifled our collaboration, now we make pre-sales quote or BOM updates from anywhere by anyone. OpenBOM has unlocked my groups’ ability to work on multiple levels of the BOM simultaneously while OpenBOM multi-level formulas allow for synchronization of big calculations and saves hours over Excel.”

Check for more customer stories and online reviews.

Conclusion

Streamlining information flow is the most important aspect of a company’s digital transformation process. While replacing individual siloed components can move the company forward (eg. moving from desktop CAD to cloud CAD), only a holistic approach that allows connecting all solutions together will become an ultimate winner to optimize the information flow.

REGISTER FOR FREE and check how OpenBOM can help you today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.