One of my favorite engineering communities in the world is SOLIDWORKS Users. It has been 25 years since Jon Hirschtick and his team founded SOLIDWORKS.

These days SOLIDWORKS is the de-facto standard for mechanical design and the system is probably used in all colleges and universities across the world to teach future engineers. I can’t even begin to count the number of amazing products that have been created using SOLIDWORKS.

Is There Room For Improvement?

As I’ve mentioned above, SOLIDWORKS is a great tool that has helped countless individuals in numerous engineering fields, but here is the thing… SOLIDWORKS was created at a time when “File” was a basic collaboration paradigm.

So, when you need to pull the data from SOLIDWORKS, such as Bill of Materials, attach some additional information (eg. Drawings), you’re left alone with Excel spreadsheets, Emails and a bunch of other funky tools like cloud storage (eg. Google Drive or similar).

It’s All About The Data!

If you work for a company or even if you’re a contractor, everyone needs the data. Guess what? Nobody really likes to manage this data.

Bill of Materials (BOM) is the lifeblood of every product development and manufacturing process. Engineering and manufacturing organizations are heavily relying on BOMs and related information in order to plan, coordinate and communicate a variety of activities. While SOLIDWORKS design can be efficient, the data management and collaboration around the data is done in a very inefficient way. And this is a place where a BOM in Spreadsheets is a leading trouble maker.

Think about pulling a multi-level product structure, converting it into a BOM, adding description, cost and supplier information, rollup cost, adding and correcting some information (Eg. excluding Purchased Assemblies, adding some materials) and sending it to a procurement team to order Parts.

You did it once? Great… now, make a change and do it a second time :). Now do you see the problem?

If you’ve been around engineering and SOLIDWORKS design, you will know that the task described above is just crazy. And if you don’t have a single Top-Level assembly designed in SOLIDWORKS, you can join Tom Cruise in his next mission impossible movie.

Moving Away From Static Spreadsheet Is A Must!

The number one pain point for SolidWorks is using Excel and spreadsheets to manage your parts and BOMs. The pain starts from creating your original BOM, sharing with other people that need to consume the information (eg. procurement) and keeping it in sync between all members of your team, contractors and suppliers. These Excels (or even Google Spreadsheets) are a mess and a source of confusion and mistakes.

Calculation is another source of royal pain. Think about rolling up a cost for an assembly or even worse, trying to figure out how many parts you have in a few assemblies together. As you work downstream you’re cloning these Excel spreadsheets and you never know which one has the latest updated cost and description.

OpenBOM is Your Key To Breaking Away From Outdated Spreadsheets

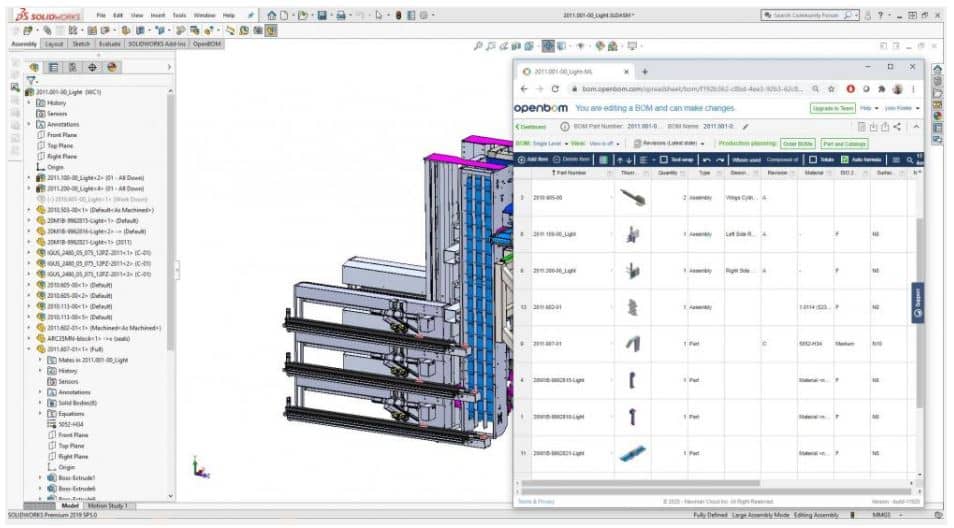

But there is some good news… OpenBOM is a way to escape Excel madness. OpenBOM integrates with CAD tools such as SOLIDWORKS, allowing you to create BOMs from SOLIDWORKS in a matter minutes, managing a single source of information, extracting data, uploading files, supports calculation, instant data sharing, BOM revisions and many other features.

Yes, you can create a BOM of thousands of unique parts with a single click and if your design changes, OpenBOM will merge changes to OpenBOM and instantly share relevant data with contractors and suppliers.

OpenBOM helped thousands of engineers using SOLIDWORKS to solve these problems. But please don’t take our word for it. Read dozens of customer stories and G2 Crowd reviews. We collected some examples for you. Take a look below.

Check the quote from Garrett Rini – Lead Mechanical Engineer at FlyPyka. Here is the article.

“FlyPyka relies on OpenBOM for Solidworks integration to reliably capture product structure and design intent. Our airplanes have lots of parts and assemblies to keep track of… and we need to be on the same BOM all of the time. Getting all of that info straight was a big problem and Google sheets wasn’t going to get us there.”

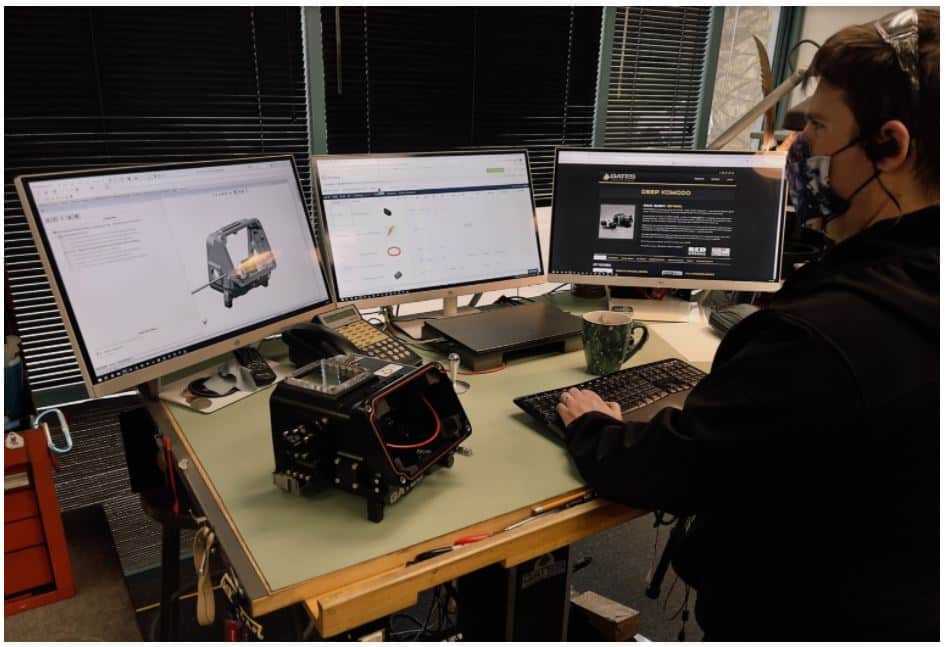

Check out their Story John Ellerbrock – President of Gates Underwater Products:

“I did not anticipate the overall benefit of the Solidworks integration… In the end, we will have a fully digital representation of our products in Solidworks and OpenBOM”

A few quotes from OpenBOM reviews on G2 Crowd website.

“The best thing about the OpenBOM software was how well it integrated with SolidWorks to help us organize our business around the CAD designs!” – Check out this G2 Review

“OpenBOM is highly configurable: It allows us to generate sub assemblies, sub modules, as well as our complete instrument build. With the linkage back to our CAD system (Solidworks), the engineering team’s time is minimized, allowing for them to work on other tasks. We also manage our vendor lists & key items as part of the system.– “Check out this G2 review

“With the linkage back to our CAD system (Solidworks), the engineering team’s time is minimized, allowing for them to work on other tasks. We also manage our vendor lists & key items as part of the system.” – Check out this G2 Review

Conclusion

OpenBOM integration with SOLIDWORKS is state of the art. Combined with OpenBOM’s flexible data management in the cloud is an ultimate solution to help engineers and manufacturing companies to capture SOLIDWORKS information, recombine with other product data and set up a new standard for collaboration in manufacturing companies.

Check OpenBOM today. Register for FREE and start a 14-days trial.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.